An integrated air valve for a massage appliance and an air massage appliance

A technology for forming air valves and appliances, which is applied in the field of air valves and air massage appliances, which can solve problems such as the inability to guarantee the massage effect, and achieve the effect of reducing the number of parts and reducing the difficulty of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

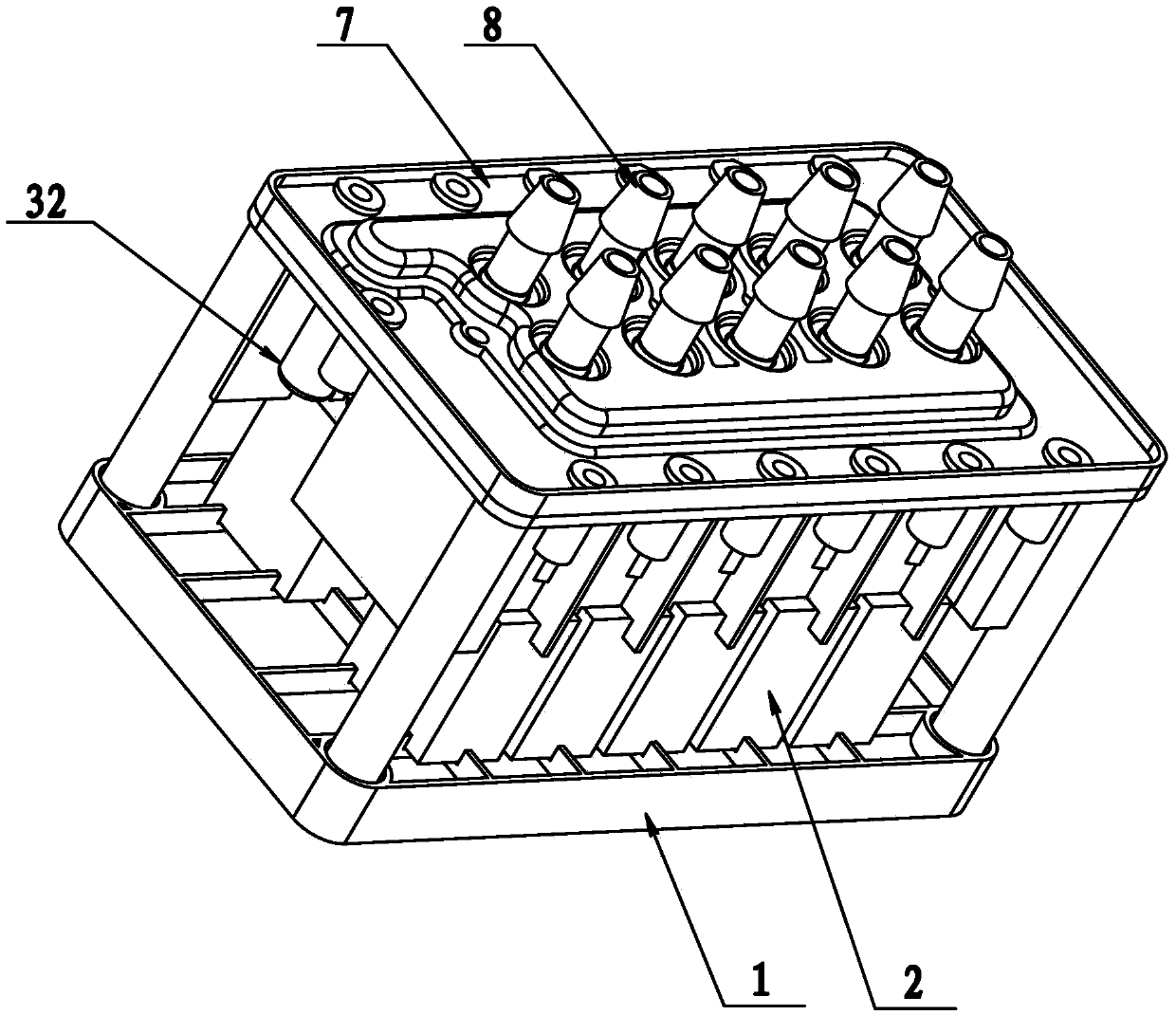

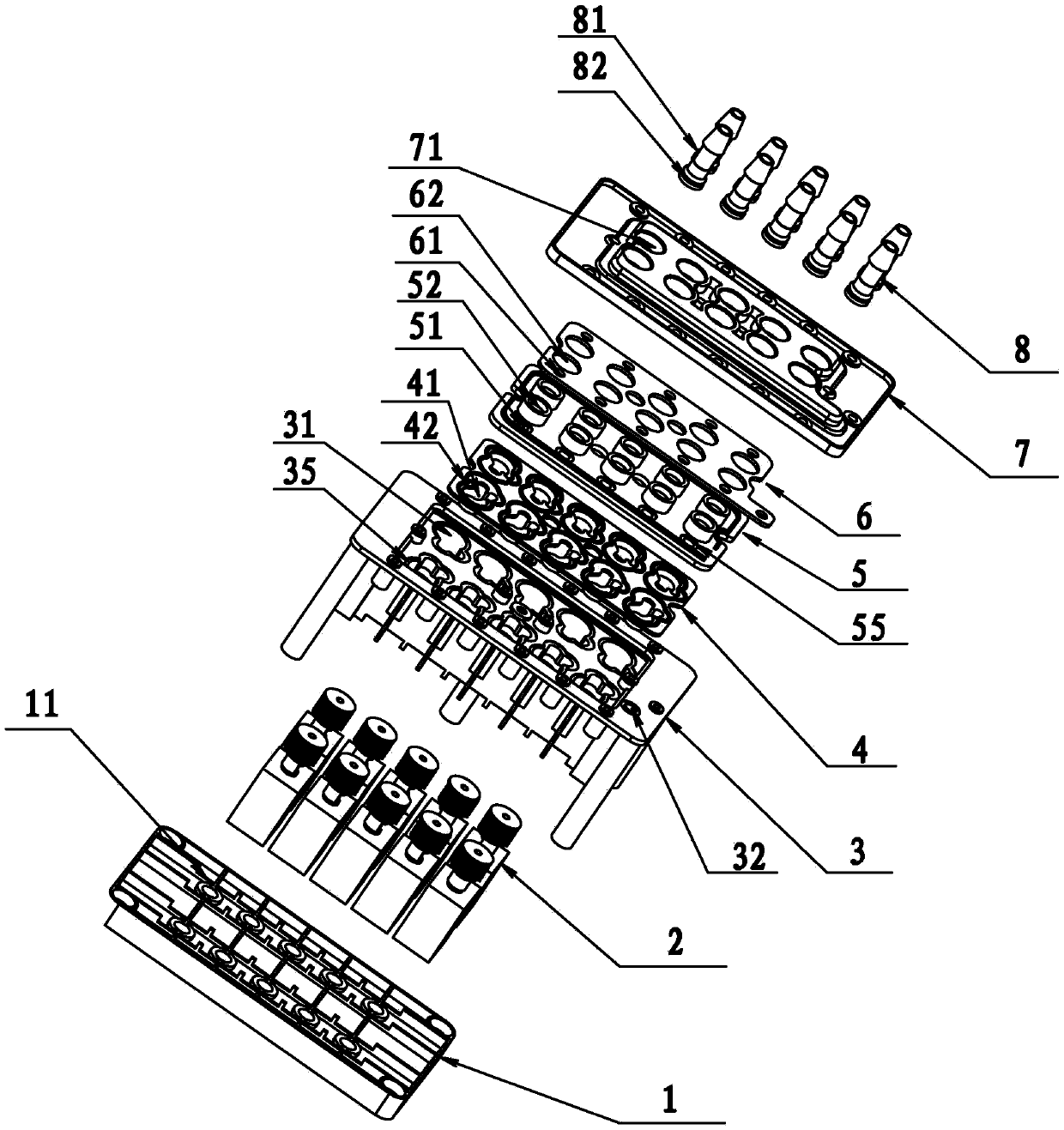

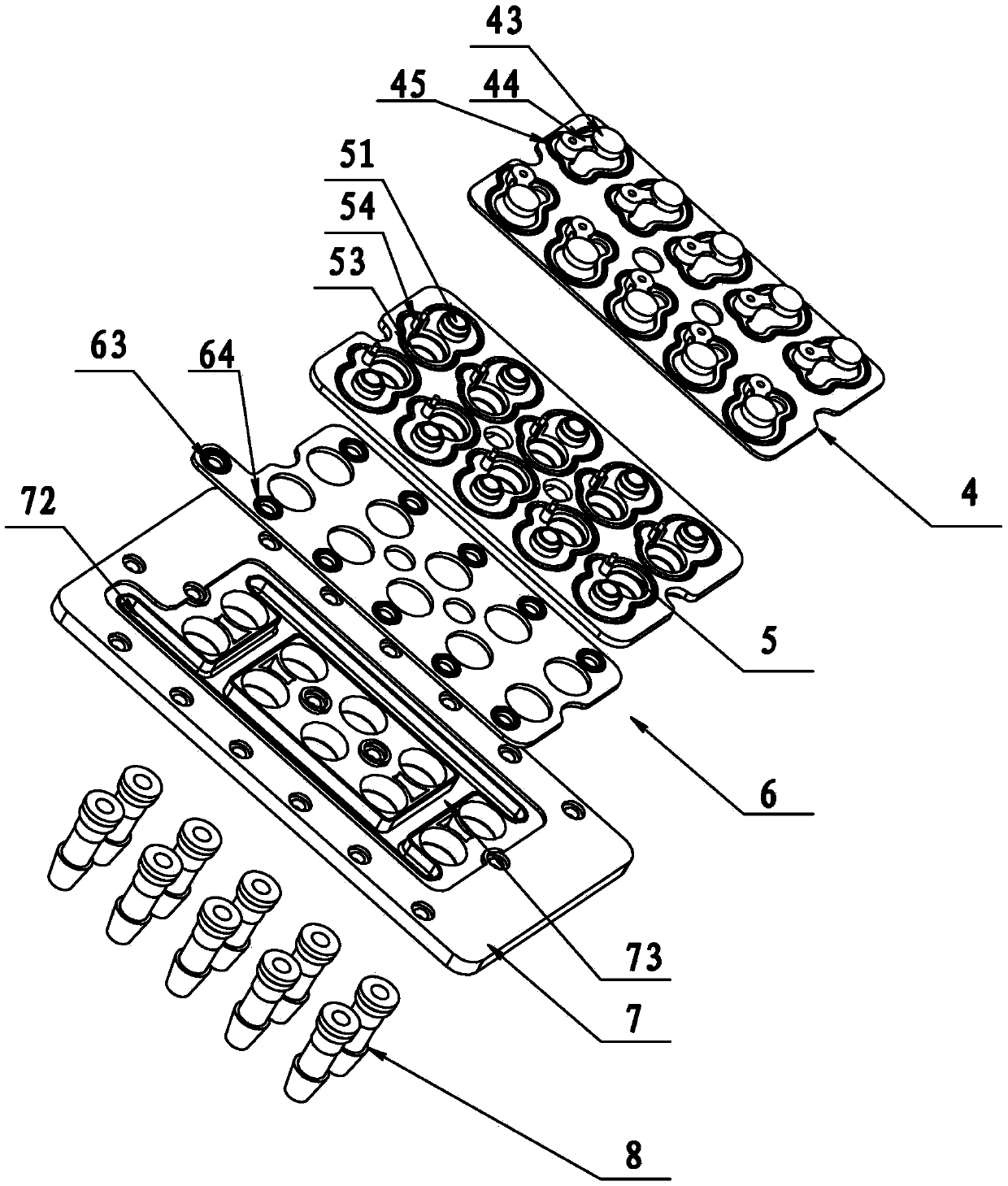

[0035] Such as figure 1 with figure 2 As shown, an integrated air valve of the present invention includes a base 1, an exhaust valve 2, a valve body 3, a valve clack substrate 4 and a valve cover. The valve cover includes a flow dividing plate 5, a sealing partition 6, an upper cover plate 7 and a gas pipe 8. There are two horizontal air supply grooves 72 on both sides of the upper cover plate 7, two vertical air supply grooves 73 in the vertical direction, and the vertical air supply grooves 73 are connected to the two horizontal air supply grooves 72 to form a crisscross pattern. The air supply groove of the air supply groove, the air supply groove and the sealing partition 6 form an air inlet passage, and the sealing partition 6 is provided with two rows of branch ports 61 at the corresponding position of the air inlet passage. There are two rows of air outlet holes A71 in the middle of the upper cover plate 7, a total of ten. The sealing partition 6 is provided with a pa...

no. 2 example

[0046] Such as Picture 10 with Picture 11 As shown, the valve cover of the present invention can be assembled into an upper cover 9. The upper cover 9 is provided with an air inlet 91, a vertical air inlet channel 92, and a lateral air inlet channel 93. The lateral air inlet channel 93 and the vertical air inlet channel 92 form the air inlet channel of the upper cover 9. With a shunt 98. The upper cover 9 is also provided with a check port 94 and an air delivery port 95, and the air inlet 91 and the check port 94 are in communication with the air inlet channel at the same time. The check port 94 is provided with a limit rod 96 and a sealing step D97 on the side of the disc substrate 4. The sealing step D97 cooperates with the annular sealing rib bonnet 42 of the disc substrate 4 for sealing, and the limit rod 96 is connected to the connecting arm 44 The positioning holes match with each other, so that the disc can accurately open or close the check port 94. The air delivery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com