A non-refillable valve and its realization method

A non-repetitive, valve technology, used in lift valves, valve details, control valves, etc., can solve problems such as poor sealing performance and affect use, and achieve the effect of eliminating secondary filling, facilitating installation, and eliminating repeated filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

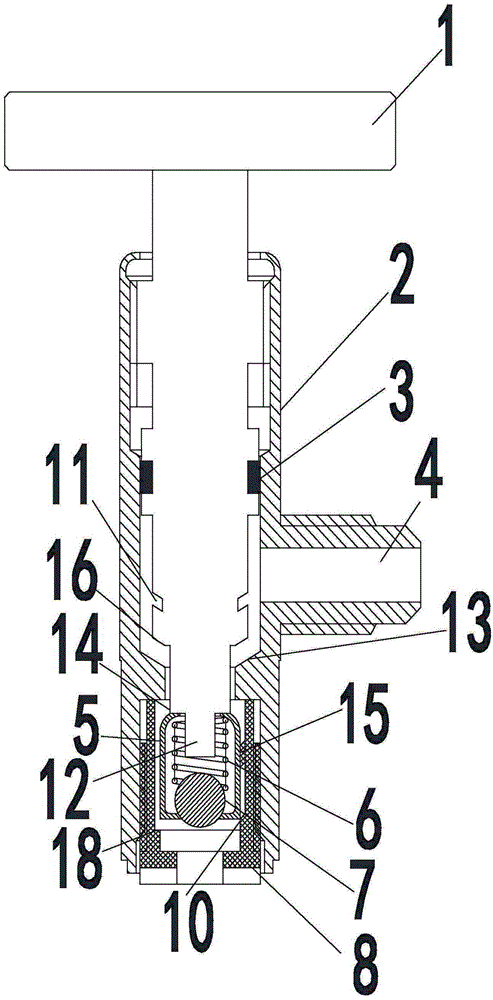

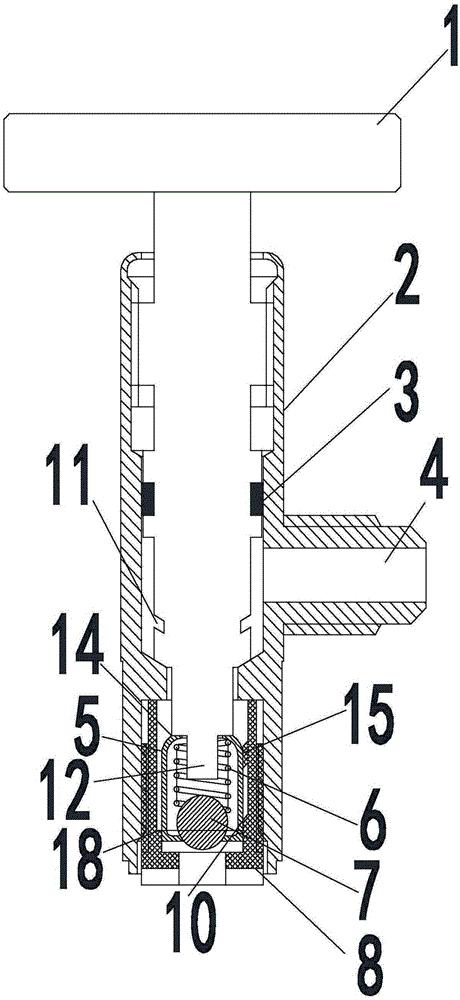

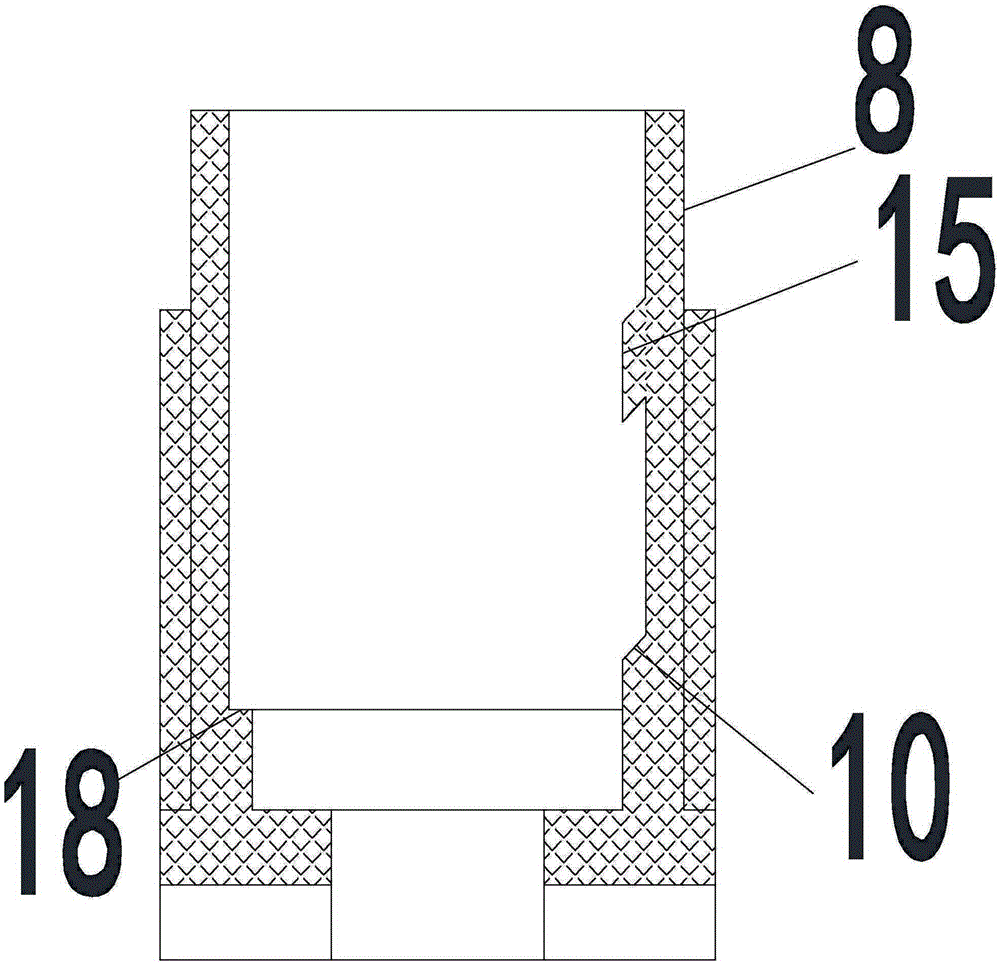

[0039] Such as Figure 1~4 As shown, a non-refillable valve includes a valve stem 1, a valve body 2, a sealing ring 3, an air inlet 4, a steel ball seat 5, a spring 6, a steel ball 7 and an inner sealing seat 8; wherein, the valve 1 The rod penetrates into the valve body 2, the air inlet 4 is set on one side of the valve body 2, and the sealing ring 3 is set inside the valve body 2, and the sealing ring 3 wraps the valve stem 1, specifically the middle and upper part, the purpose of the sealing ring 3 setting It is to prevent the gas from leaking out and escaping from the top; there is an installation part in the bottom of the valve body 1, and an inner sealing seat 8 is installed in the installation part, and a steel ball seat 5 is arranged in the inner sealing seat 8, and the gap between the inner sealing seat 8 and the steel ball seat is 5 The relationship: when not inflated, there is an inflation channel between the inner sealing seat 8 and the steel ball seat 5, when the ...

Embodiment 2

[0055] The difference between this embodiment and Embodiment 1 is that the spring 6 in this embodiment has a stiffness coefficient of 1.5 N / M, and an inclined groove 11 is provided on the valve stem 1 above the annular slope 16 with a width of 2 mm and a depth of 1 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com