Array substrate and display device

A technology for array substrates and material layers, applied in instruments, semiconductor devices, optics, etc., can solve the problems of reduced display quality, large spacing, and reduced storage capacitance, and achieve improved pixel aperture ratio, improved display quality, and increased storage capacitance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

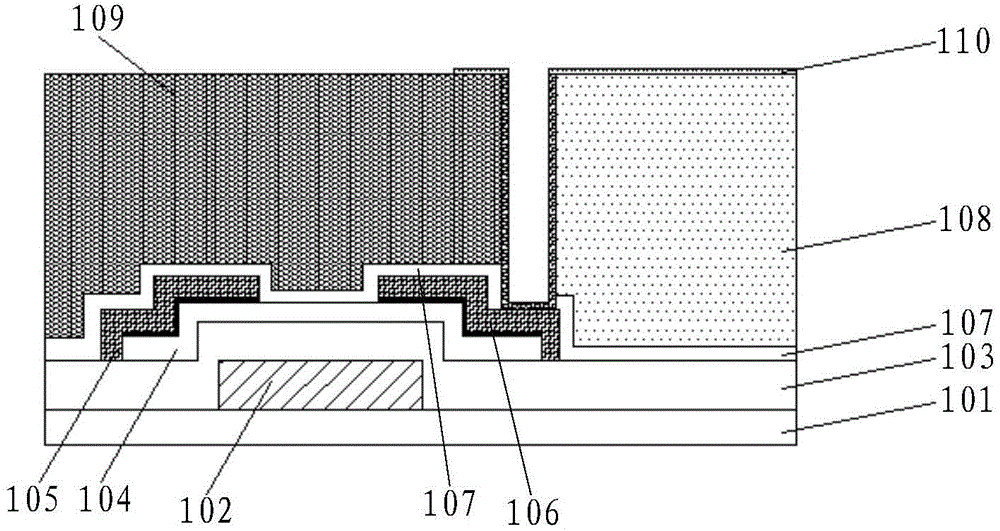

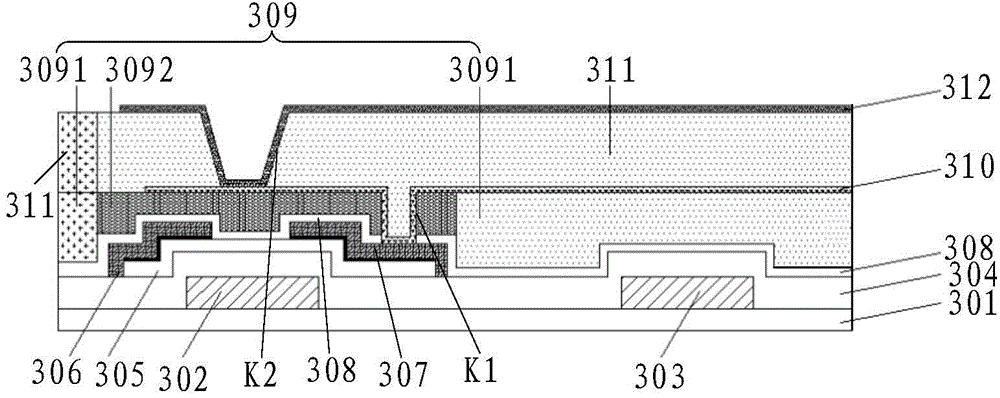

Embodiment 1

[0038] This embodiment provides an array substrate, including: a thin film transistor, a pixel electrode, and a common electrode; the array substrate further includes: a first material layer located on the thin film transistor, and a first via hole is located in the first material layer; The conductive interlayer on the first material layer, the conductive interlayer is electrically connected to the drain of the thin film transistor through the first via hole; the second material layer located on the conductive interlayer, the second material layer has a structure interconnected with the first via hole The second via hole is staggered, the pixel electrode is located on the second material layer, and the conductive interlayer is electrically connected to the pixel electrode through the second via hole to form a storage capacitor with the common electrode; wherein, the first material layer located on the array substrate The material of the part in the opening area and the materia...

Embodiment 2

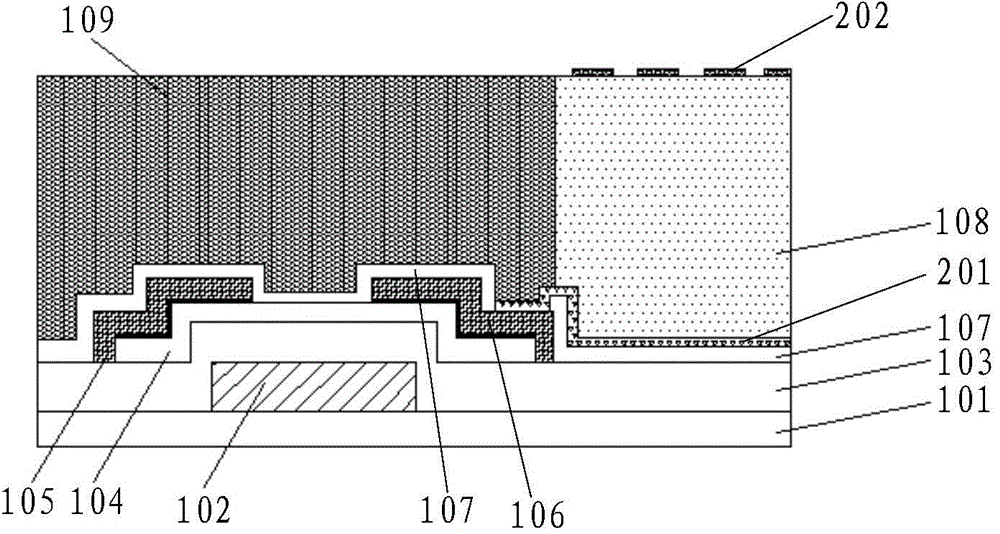

[0064]This embodiment provides an array substrate, including: a thin film transistor, a pixel electrode, and an element for providing a common electrode voltage; the array substrate also includes: a first material layer located on the thin film transistor, and the first material layer has The first via hole; the first conductive interlayer and the second conductive interlayer insulated on the first material layer, the first conductive interlayer is electrically connected to the drain of the thin film transistor through the first via hole, and the second conductive interlayer is connected to the drain of the thin film transistor. The components used to provide the common electrode voltage are electrically connected; the second material layer located on the first conductive interlayer and the second conductive interlayer has a second via hole that is staggered from the first via hole on the second material layer , the pixel electrode is located on the second material layer, the f...

Embodiment 3

[0090] This embodiment provides a display device, which includes the array substrate as described in Embodiment 1 and Embodiment 2. The display device may be any product or component with a display function such as a liquid crystal panel, an electronic paper, an OLED panel, a liquid crystal TV, a liquid crystal display, a digital photo frame, a mobile phone, and a tablet computer. Based on the advantages of the array substrates described in Embodiment 1 and Embodiment 2 above, the display device provided in this embodiment has the advantages of high screen display stability, large pixel aperture ratio, and good display quality compared with the display devices in the prior art. etc., and the display device provided by this embodiment can be of FFS type structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com