Center calibration device for engine vibration experiment

A center calibration, engine technology, applied in the direction of engine testing, measuring device, machine/structural component testing, etc., can solve the problems of poor accurate judgment of the coaxiality of the position of the connection point, violent vibration of the body, and easy deviation, etc. To achieve the effect of shortening the experimental preparation time, strong interchangeability of parts, and ingenious production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific embodiments.

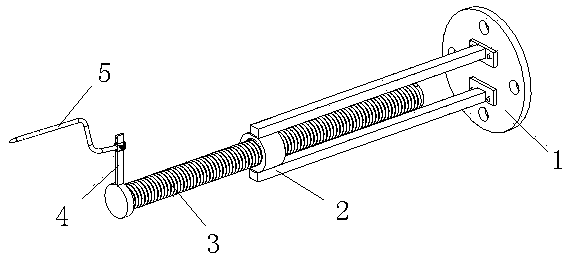

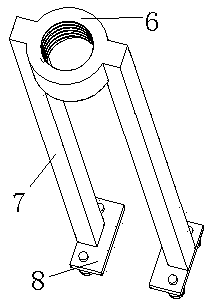

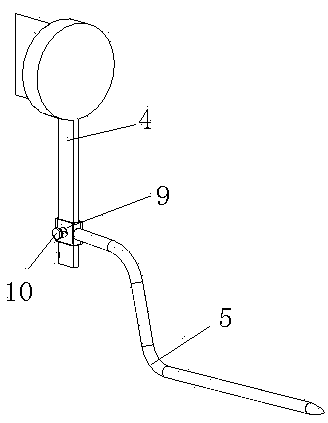

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a central calibration device for an engine vibration experiment includes a connection plate 1, and also includes a fixed bracket 2, a screw rod 3 and a detection needle 5 arranged in sequence. The bracket fixing holes are distributed in shape, and there are installation holes on the connecting plate away from the center; the fixing bracket is fixed on the connecting plate through nuts and bolts, which includes threaded sleeves 6, supporting arms 7 and fixing plates arranged in sequence from top to bottom 8. There are two support arms 7, both of which are symmetrically fixed on both sides of the threaded sleeve 6; there are two fixed plates 8, which are respectively fixed on the bottom of the support arms, and the fixed plate 8 is a rectangular structure, on which there are 2 screw holes; the layout of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com