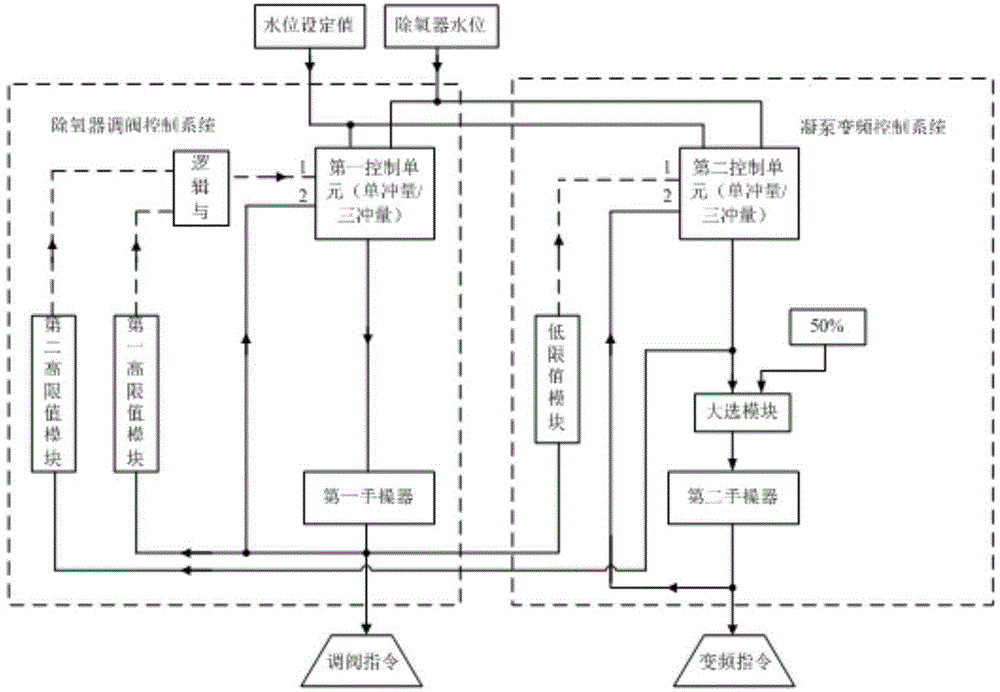

Deoxygenator water level whole-course control system and method with tracking under condensate pump frequency conversion condition

A control system, frequency conversion control technology, applied in control/regulation system, liquid level control, non-electric variable control and other directions, can solve problems such as regulation performance decline, water level fluctuation, and inability to perform water level control in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

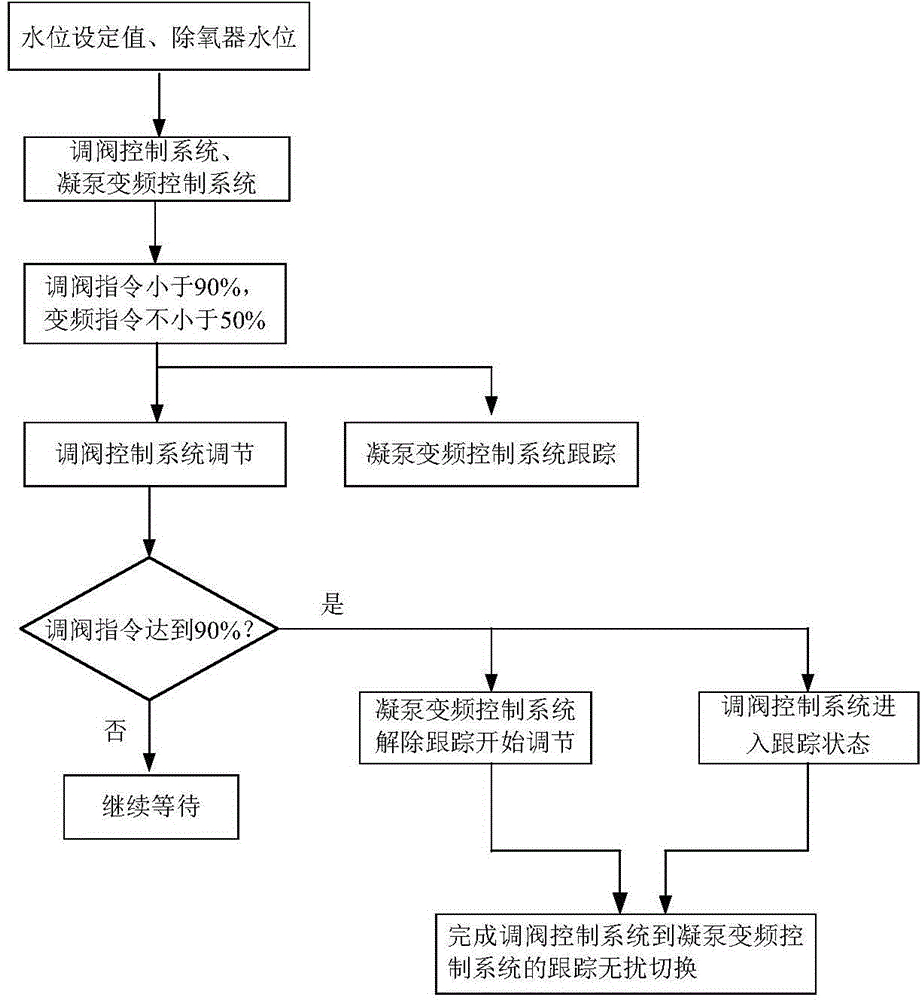

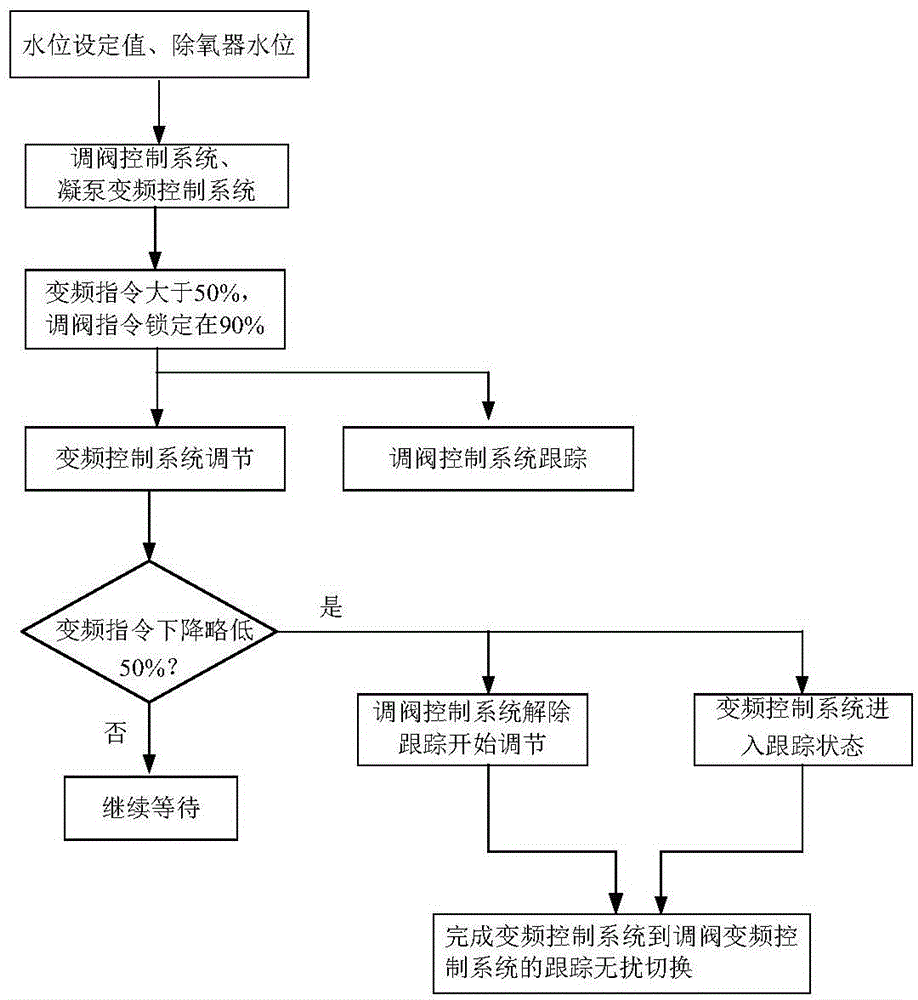

[0035] Implementation case: The program has been put into use in a unit of a certain plant, and good results have been achieved. See the site usage Figure 4 , Figure 5 As shown in the figure, ① represents the valve control command, ② represents the valve feedback, ③ represents the frequency conversion command of the condensate lift pump, ④ represents the condensate lift pump speed, ⑤ represents the deaerator water level setting value, ⑥ represents the actual water level of the deaerator , ⑦ represents generator power.

[0036] Figure 4 In ⑦ generator power, it can be seen that this is a load increase process. When the valve control command ① reaches 90%, the frequency conversion command ③ can be immediately activated, the valve control command ① is locked at 90%, and there is no disturbance in the switching process, ⑤ except There is no fluctuation between the set value of the oxygenator water level and the actual water level of the deaerator, and the water level is always cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com