Pump unit driven by an electric motor

A technology of pump components and motors, which is applied in the direction of engine components, pump components, engine functions, etc., can solve the problems of manufacturability cost and assembly investment of complex structures, and achieve the reduction of acoustic reflection, improvement of acoustic decoupling, and reduction of assembly investment small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Since the basic mode of operation of a pump assembly of the same type and of a pneumatic brake booster that can be connected to such a pump assembly is sufficiently known, it will not be described in detail hereinafter, as long as this is not considered to be necessary for the description of the present invention. Words matter.

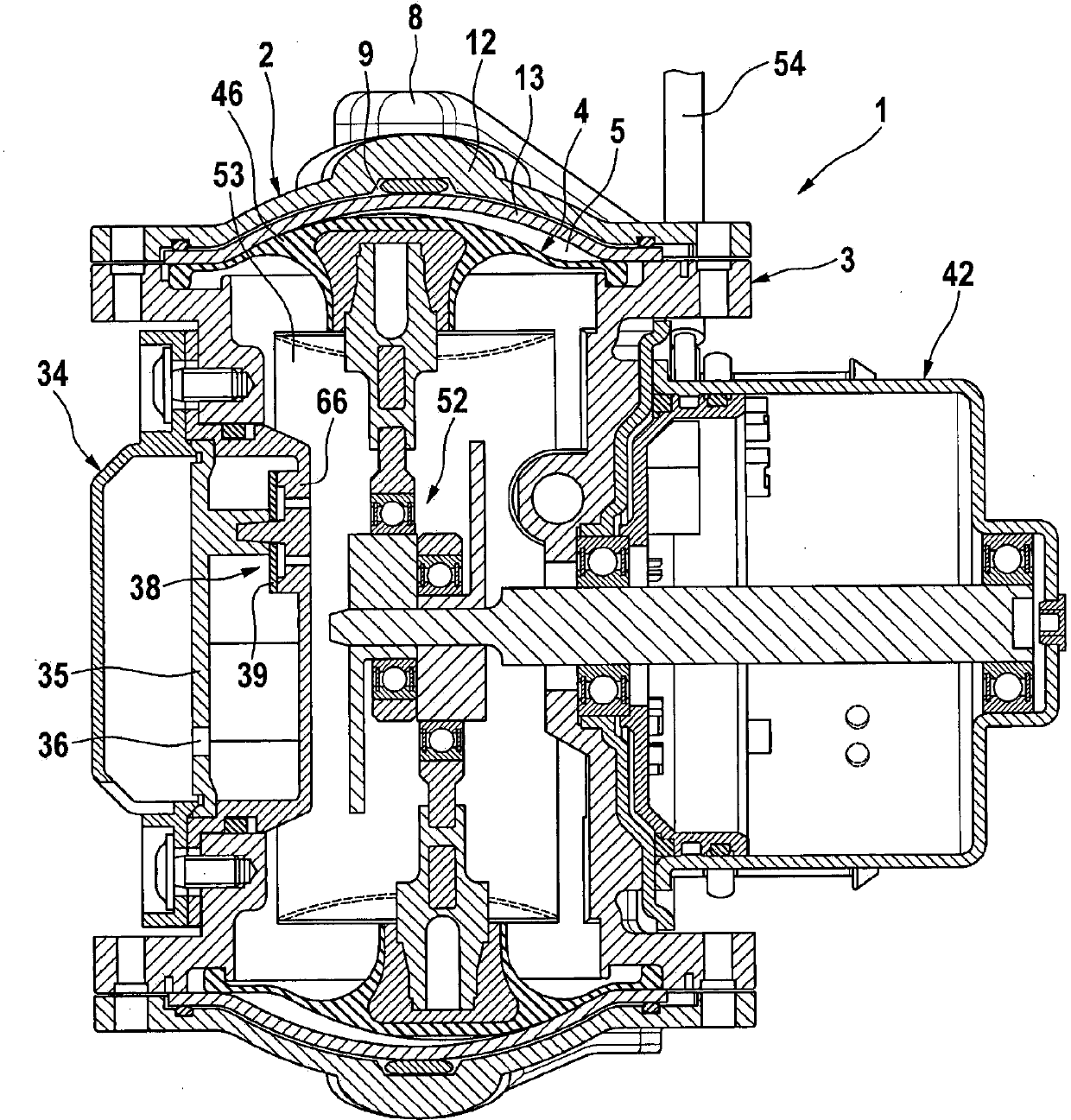

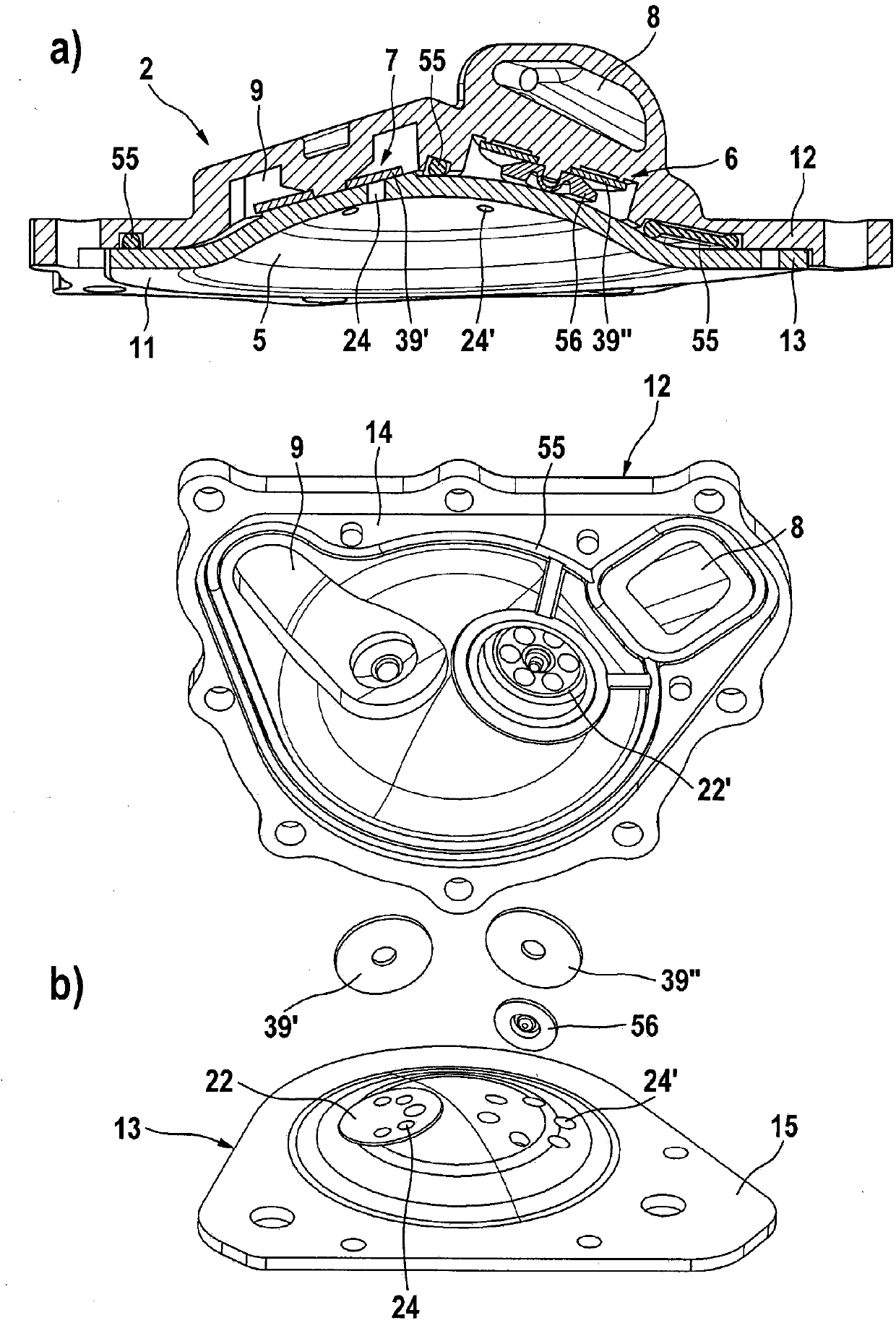

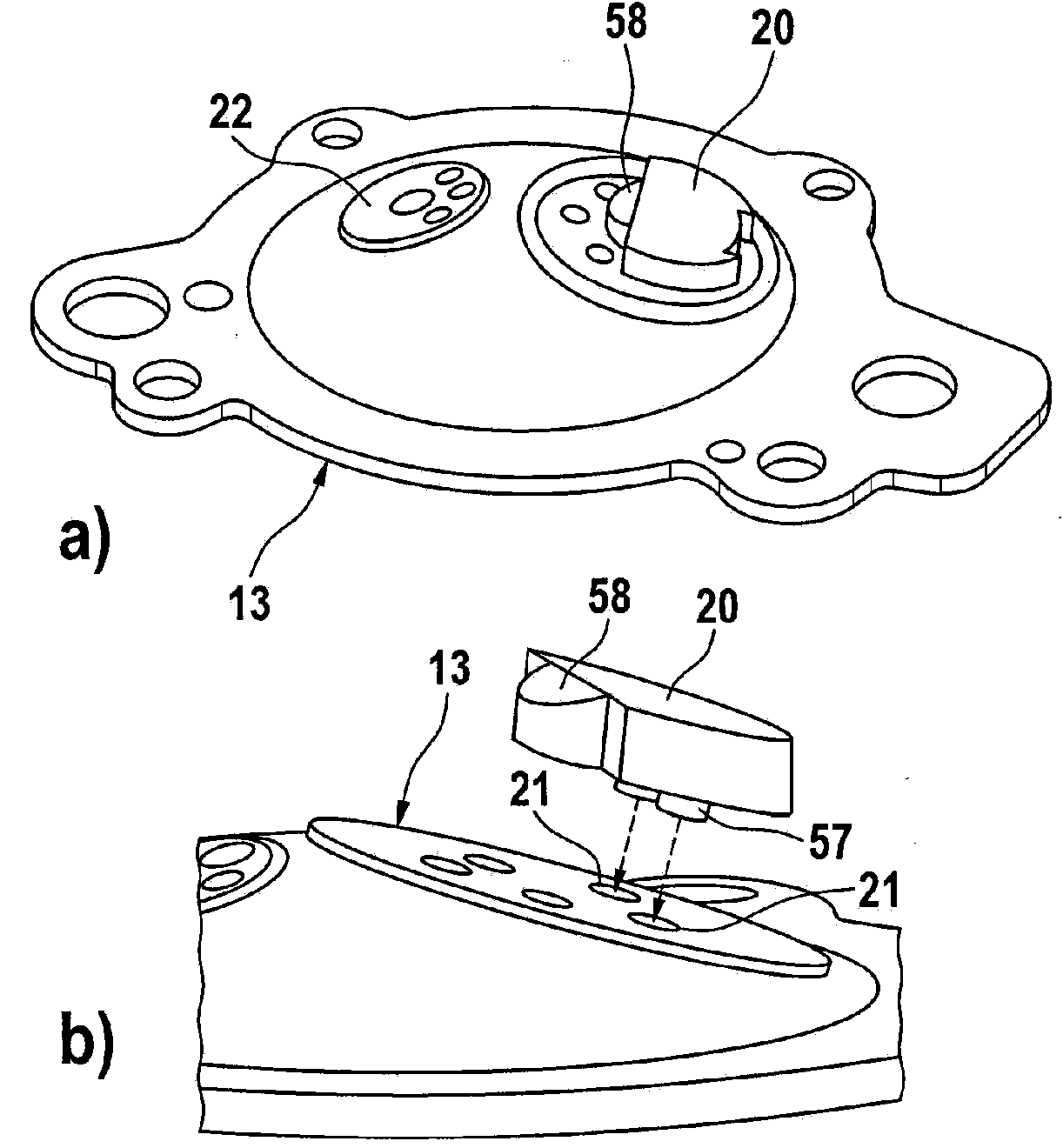

[0046] figure 1

[0047] figure 1 A known pump assembly 1 is shown. The pump assembly is designed as a double-diaphragm pump with two mutually opposite displacement elements 4 . The displacement elements 4 each have an elastic diaphragm element 46 which is respectively stretched airtight between the pump housing 3 and the working chamber cover 2 and thus delimits the working chamber 5 . An inlet valve 6 and an outlet valve 7 , not shown, as well as an inlet channel 8 and an outlet channel 9 , which are pneumatically connected to the valves, are assigned to each working chamber. In this case, inlet channel 8 is connected pneumatically to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com