Hydraulic balance valve with changeable load

A technology of hydraulic balance and cone valve, which is applied in the field of hydraulic balance valves, can solve problems such as the mismatch between balance capacity and load, and achieve the effects of improving oxygen absorption efficiency, easy processing, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

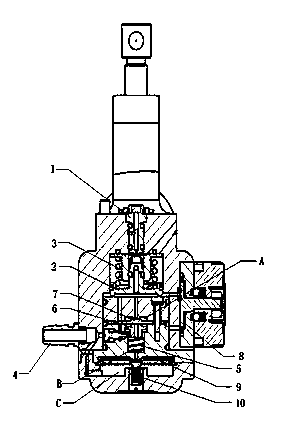

[0008] Depend on figure 1 It is known that a hydraulic balance valve with variable load includes a main valve, a load adaptation valve and a control valve. The main valve and the control valve are cone valve structures, and the load adaptation valve is a slide valve structure. There are external oil ports A and B on the valve. , K, X, the spool 10 of the load adapting valve has a series of circumferential small holes, the load adapting valve includes a strong spring 8 and a weak spring 9, a diaphragm and a spring are respectively arranged at the inlet end and the outlet end, The diaphragm at the air outlet controls the diaphragm at the intake end, and the main valve and control valve adopt a cone valve structure.

[0009] When the outside is inhaled, a negative pressure is formed, first the outlet diaphragm is opened, and then the inlet diaphragm is opened due to the decrease in internal pressure, thereby outputting oxygen; when the internal pressure is reduced to less than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com