Large-scale mining bolted-connection cylinder body adopting steel structure

A steel structure and bolt technology, which is applied in the field of large-scale mining bolts to connect steel structure cylinders, can solve the problems of non-fusion, only parts can be delivered, and long installation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

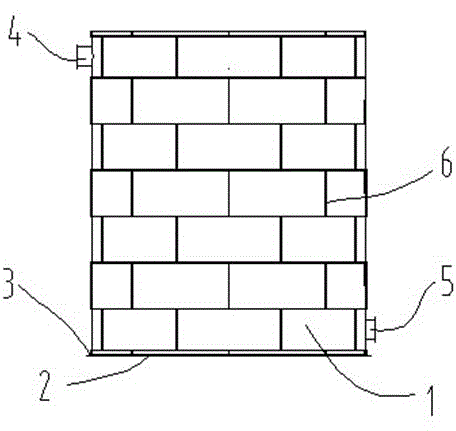

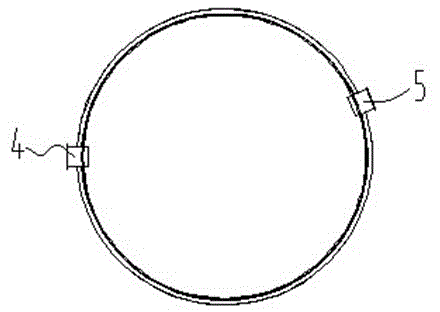

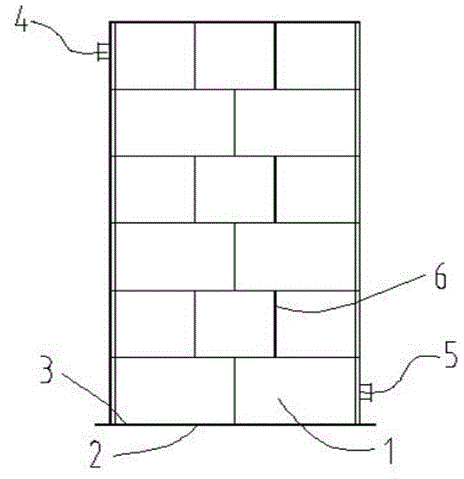

[0013] Refer to attached figure 1 , Embodiment 1, a three-dimensional structure of a circular cylinder, a large-scale mining bolted steel structure cylinder, including a wall plate 1, a bottom plate 2, a pre-embedded plate 3, an ore supply port 4, an ore discharge port 5, and a filling material 6 , Bolt 7, characterized in that: the cylinder wall plate 1 is composed of multiple sections of cylinder joints, which are coaxially arranged and connected by bolts 7; the cylinder joints are composed of multiple sections of steel plates with flange surfaces, and the Filling material 6 is added to the flange surface between them, and bolts 7 are used to connect the wall plate 1 forming the cylinder; filling material 6 is added to the joints of each flange surface of the wall plate 1, and the adjacent flanges and filling material 6 are connected with bolts 7 The connection is fixed; the wall plate 1 of the cylinder is provided with an ore opening 4 and an ore discharge opening 5; a laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com