A kind of cnc milling process of milling tool and aluminum decorative strip-like curved surface gap

A technology of milling cutters and milling cutters, which is applied in the direction of milling cutters, manufacturing tools, milling machine equipment, etc., can solve problems such as complex features, inability to accommodate accompanying objects, and inability to realize mass production in a rhythm, so as to achieve high-efficiency mass production and meet the production cycle rate Requirements and achieve the effect of milling surface quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

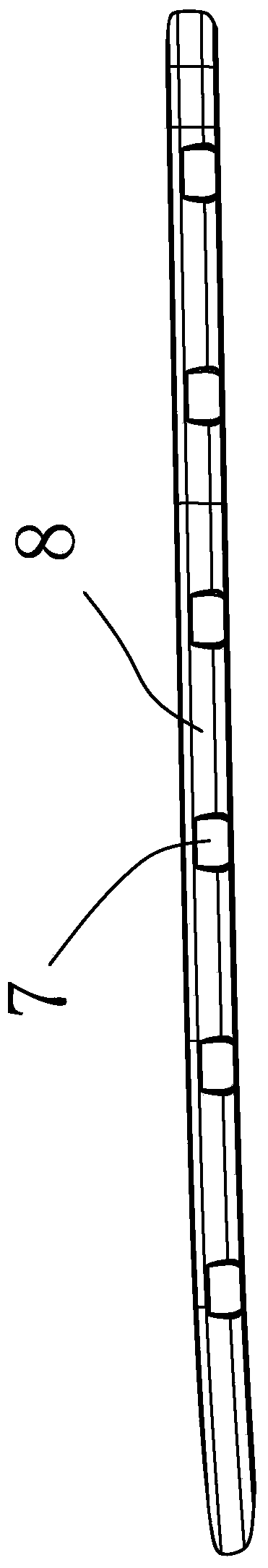

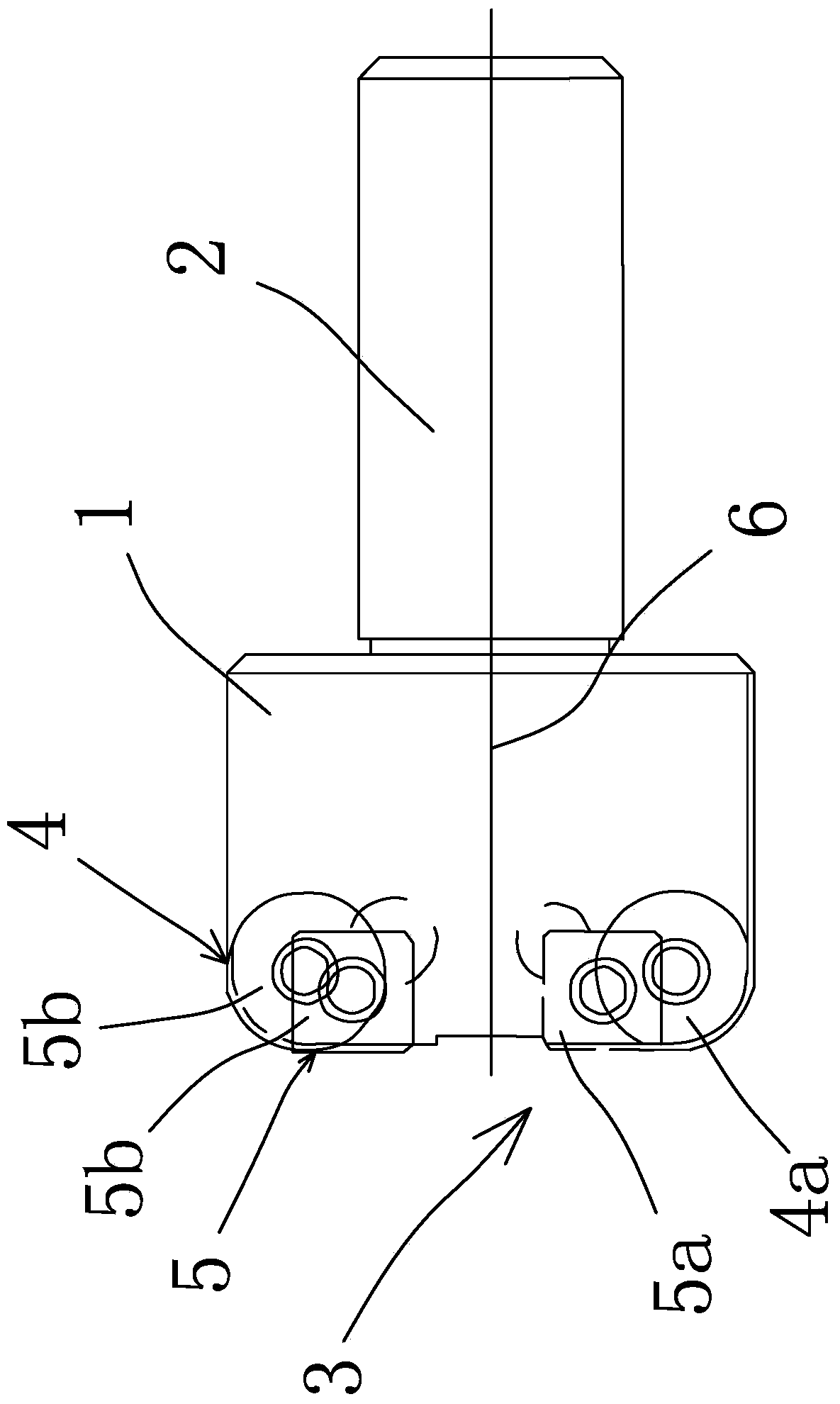

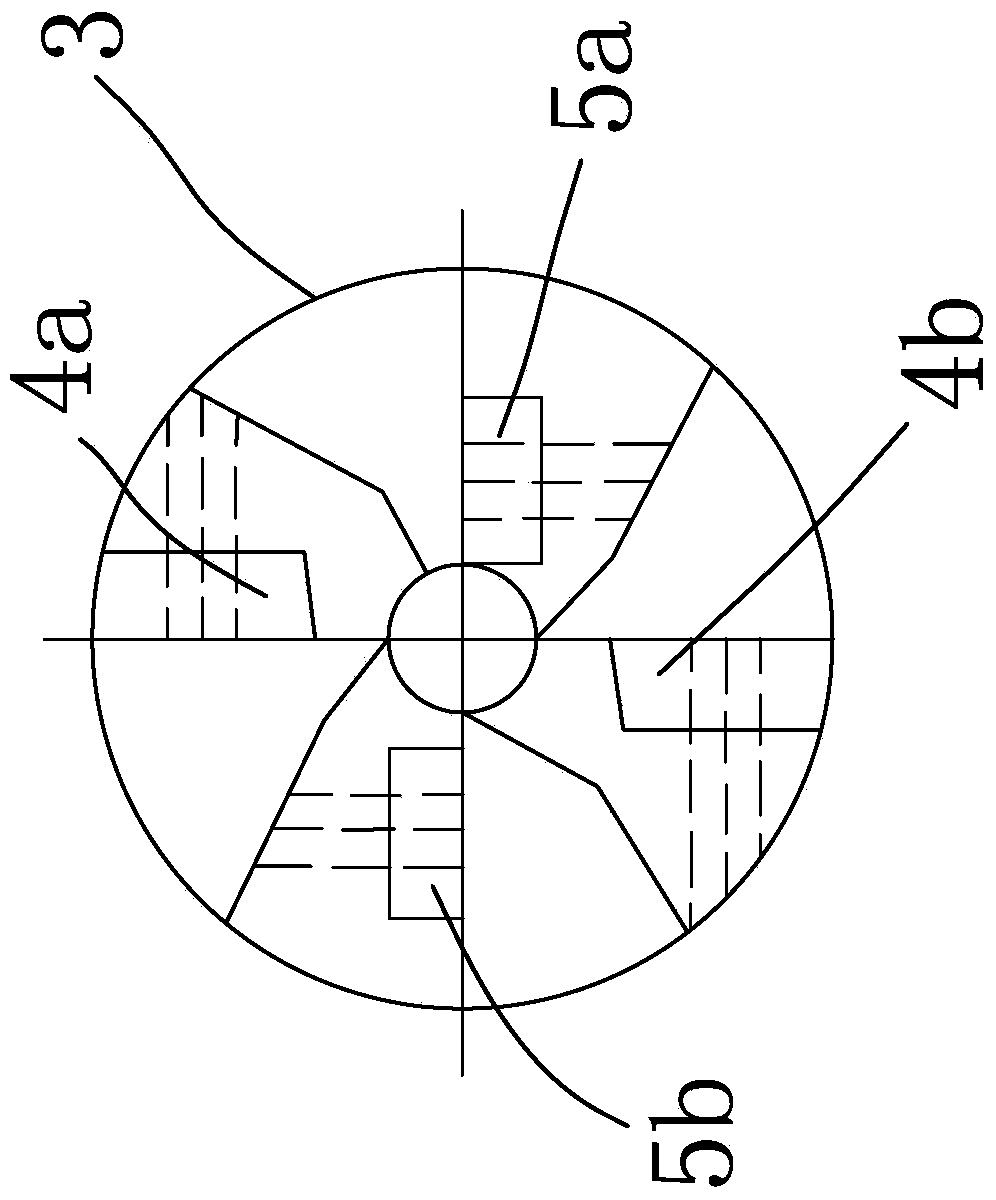

[0031] In the figure, body 1; handle 2; milling cutter body 3; round cutter grain 4; first round cutter grain 4a; second round knife grain 4b; square knife grain 5; first square knife grain 5a; second square knife Grain 5b; Knife handle center line 6; Curved surface gap 7; Luggage rack 8; First path trajectory 9; Second path trajectory 10; Third path trajectory 11; Fourth path trajectory 12; ; Area Two 13b; Vacant Area One 13c; Second Area 14; Area Three 14a; Area Four 14b; Vacant Area Two 14c; Third Area 15; Area Five 15a; Area Six 15b; Vacant Area Three 15c; the fourth area 16; area seven 16a; area eight 16b; vacant area four 16c.

[0032] Such as figure 2 As shown, the milling tool is mainly used to mill out the curv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com