Wing of ornithopter

A wing and airfoil technology, applied in the field of flapping wing, can solve the problems of not being suitable for micro-aircraft, low efficiency, complex structure, etc., and achieve the effect of simple structure, small resistance, large lift and thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

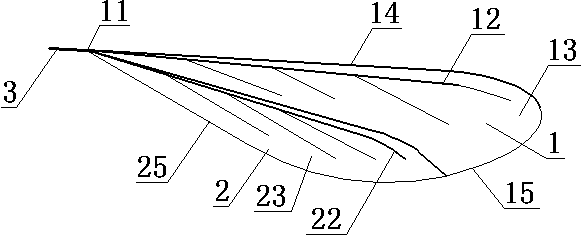

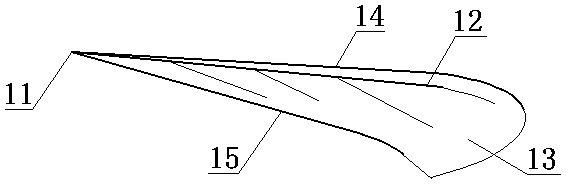

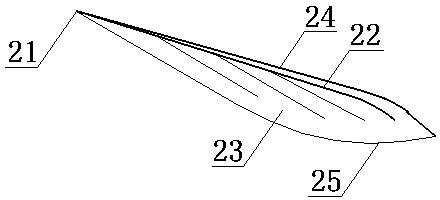

[0010] now attached Figure 1~4 The present invention is described in detail: a flapping wing, consisting of a main wing 1, an aileron 2 and a rocker 3. The main wing 1 includes the main wing root 11 , the main wing frame 12 and the main wing skin 13 , and the aileron 2 includes the aileron root 21 , the aileron frame 22 and the aileron skin 23 . Both the main wing frame 12 and the aileron frame 22 are in the shape of dendrites, the main wing leading edge 14 is relatively thick, the position where the main wing trailing edge 15 connects with the aileron leading edge 24 protrudes downward, and the aileron leading edge 24 protrudes upward, and the aileron rear edge 24 protrudes upwards. Edge 25 is thinner. The aileron root 21 is more elastic than other parts of the airfoil. The planar shape of the whole wing is similar to leaves; the leading edge of the whole wing is the main wing leading edge 14 which is relatively straight, and the leading edge at the tip of the wing has som...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com