Contourable hammer type deicing unit and deicing device with same

A unit body and hammering technology, applied in cleaning methods, snow surface cleaning, construction, etc., can solve problems such as affecting operation efficiency, increasing operation cost, and unsatisfactory cleaning effect, and achieving the effect of improving ice breaking effect and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

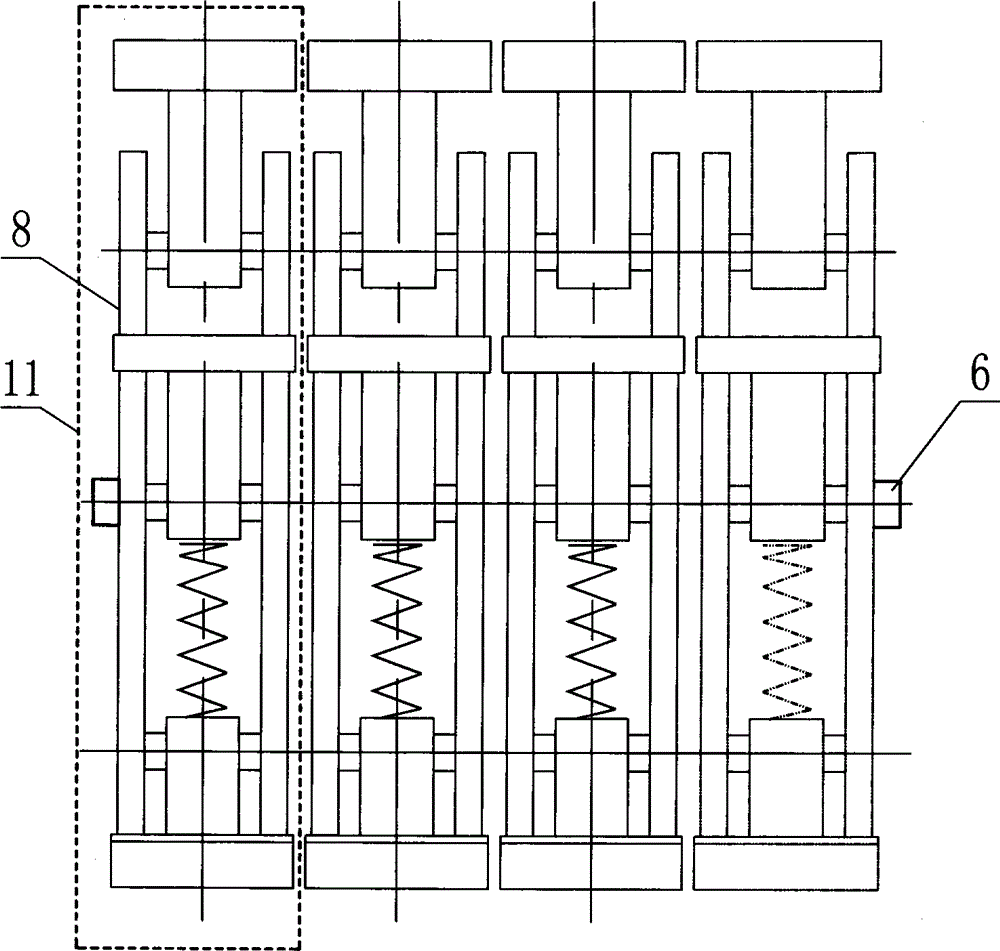

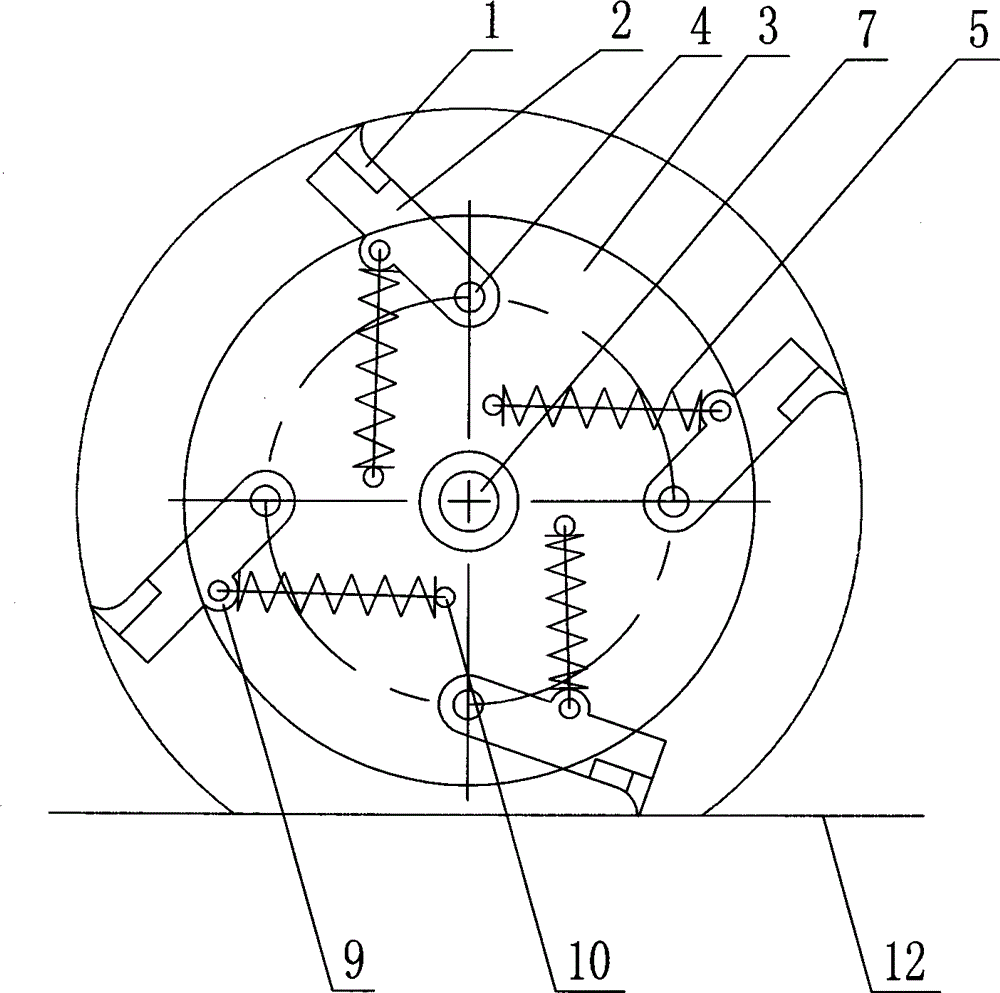

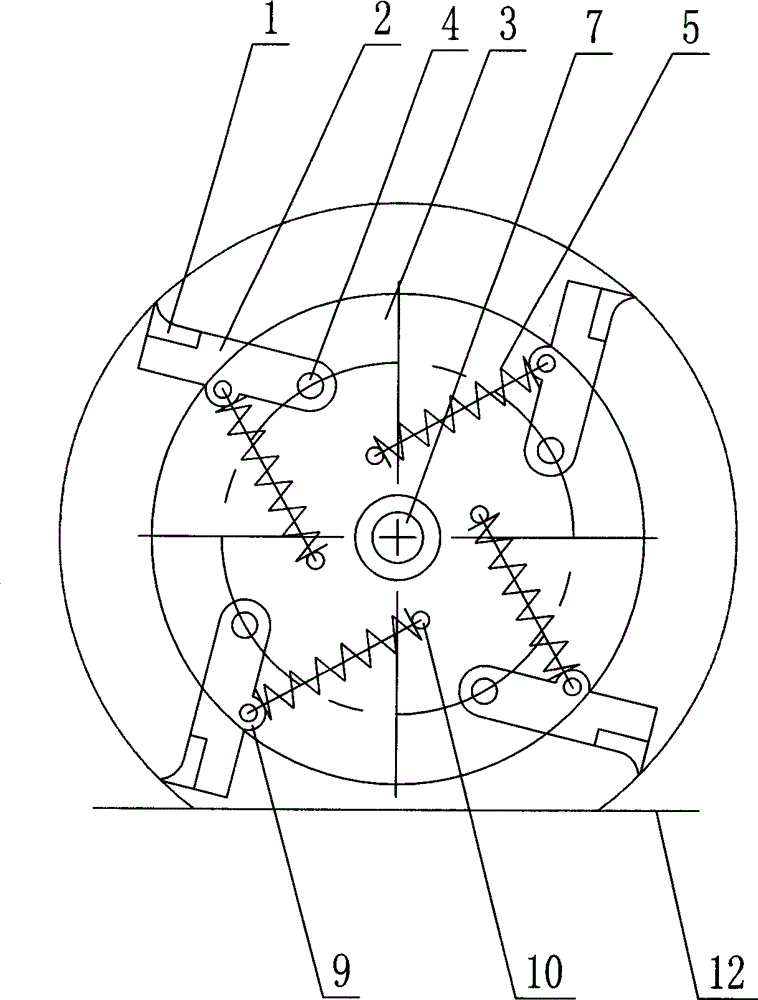

[0017] Specific implementation mode one: as Figure 1 ~ Figure 3 As shown, the profilable hammer-type deicing unit body includes a circular mounting plate 3, a plurality of swing hammers, a plurality of pin shafts 4, a plurality of springs 5, and the plurality of hammering blades 1, The number of a plurality of hammering bodies 2, a plurality of pin shafts 1 and a plurality of springs 5 is the same, and each swing hammer is composed of a hammering blade 1 and a hammering body 2, and the circular mounting plate 3 is a combination Welding parts, one end of the hammering body 2 is fixed with a hammering blade 1, the other end of the hammering body 2 is sleeved on the pin shaft 1 through the through hole ring provided on it, and the center of the circular mounting plate 3 There is a mounting hole 7 for the long axis 6 to pass through, and the circular mounting plate 3 is provided with a hollow cavity, and a plurality of pin shafts-4 are fixed axially between the two inner side w...

specific Embodiment approach 2

[0019] Specific implementation mode two: as Figure 1 ~ Figure 3 As shown in the first embodiment of the profilable hammer-type deicing unit body, the circular mounting plate 3 is composed of an outer peripheral side plate and two discs 8, and the outer peripheral side plate The two disks 8 are arranged facing each other, and the long strip plate bent into an arc is arranged on the outer surface between the two disks 8. At the edge of the circumference, two discs 8 are welded with the strip plate bent into an arc shape.

specific Embodiment approach 3

[0020] Specific implementation mode three: as figure 2 , image 3 As shown in the specific embodiment 1, the profilable hammer-type deicing unit body, the hammer body 2 is a strip-shaped plate, and one corner of one end of the hammer body 2 is processed with a A right-angled notch, the hammer blade 1 is fixedly arranged at the right-angled notch of the hammer body 2 . Hammer blade 1 is damaged and replaceable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com