Multilayer multi-foot frame structure and construction method thereof

A construction method and a multi-pod technology, which can be applied in infrastructure engineering, underwater structures, artificial islands, etc., can solve the problems of difficult leveling, difficult installation, and many construction procedures on the water, so as to improve the overall rigidity and stability Sexuality, reducing construction time and cost, avoiding the effect of sending piles and clamping piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention are described in detail below.

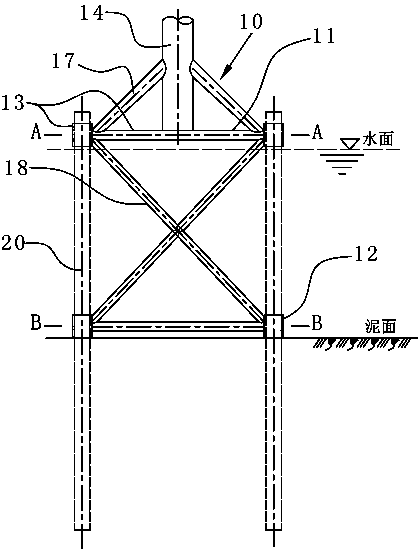

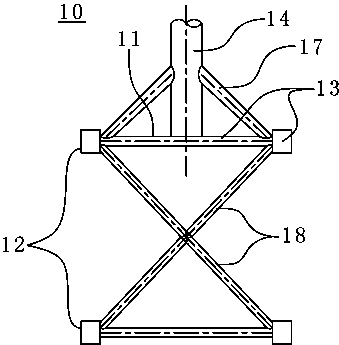

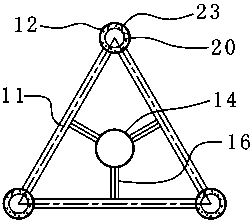

[0037] refer to Figure 1~4As shown, the figure shows a multi-layer multi-legged frame structure of the present invention, which includes at least two horizontally arranged multi-legged frames 13 arranged in layers at different elevations, and diagonal braces that connect each layer of multi-legged frames into a whole Rod 18, multi-legged frame 13 is surrounded by a plurality of connecting rods 11 to form a polygon and is provided with a cylindrical steel leg tube 12 at the polygonal apex, each layer of multi-legged frame 13 and the diagonal struts 18, steel Column 14, horizontal connecting rod 16, and oblique connecting rod 17 are processed and fixedly connected in the factory to form an integral structure—a multi-layer trivet frame body 10. Among them, the steel leg tube 12 is pierced with a secondary additional foundation pile 20, and an annular seam is reserved between the steel leg tube 12 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com