Self-pressurizing system of gas cylinder

A self-pressurization and gas cylinder technology, applied in the direction of charging system, oil supply device, internal combustion piston engine, etc., can solve the problems of liquefied gas leakage, hidden dangers, low efficiency of air heating and heat transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

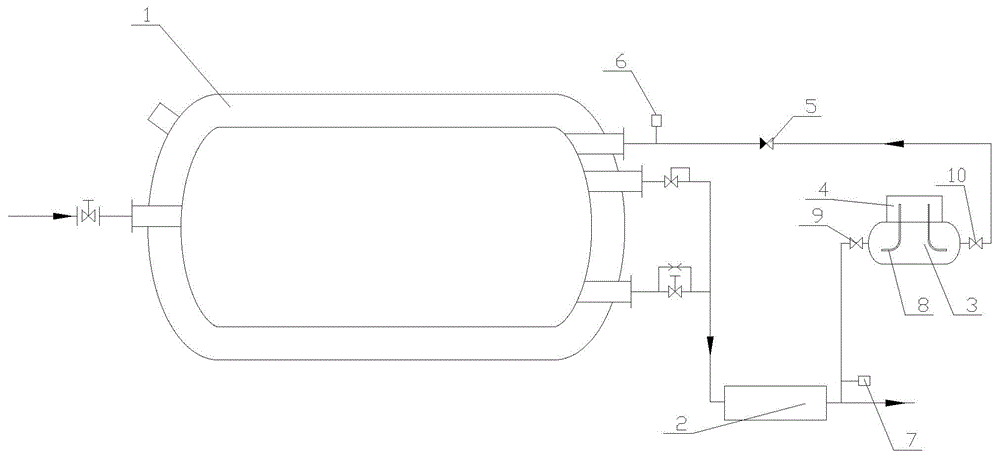

[0018] Such as figure 1 As shown, a self-pressurization system for LNG vehicle-mounted cylinders includes a gas cylinder 1, the liquid outlet of the gas cylinder 1 is connected to the water bath type vaporizer 2 through a pipeline provided with an electronically controlled liquid outlet valve, and the water bath Type gasifier 2 communicates with the automobile engine cooling water system. The outlet of the water-bath gasifier 2 is provided with a tee, one outlet on the tee is connected to the automobile engine through a pipeline, and the other outlet on the tee is connected to the gas storage tank through a pipeline, and the gas storage tank is connected to the gas storage tank through the pipeline. The pipeline is connected to the gas phase port of the gas cylinder 1 and a pressure sensor 6 and a check valve 5 are arranged on this section of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap