Hub for axial flow fan

A technology of axial fans and hubs, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of complex processing process, low overall strength, complex structure, etc., achieve compact and beautiful appearance, and reduce equipment cost , The effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention is further described:

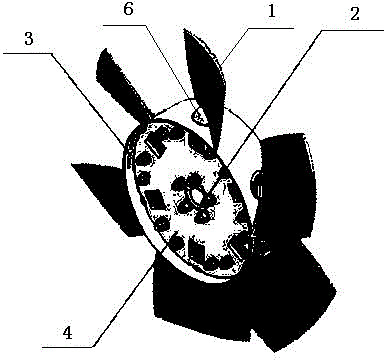

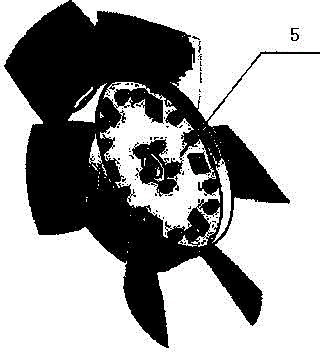

[0012] As shown in the drawings, a hub for an axial flow fan includes a blade 1, which is characterized in that it is provided with a shaft disk 2, a rim 3, a front pressure plate 4, a rear pressure plate 5 and a blade fixing shaft 6, and the shaft disk 2 is arranged on the wheel. The center of the ring 3, and the axle disc 2 and the wheel rim 3 are coaxial, one end of the axle disc 2 is fixedly connected with the front pressure plate 4 through a fixing bolt and a fixing nut, and the other end is fixedly connected with the rear pressure plate 5 through a fixing bolt and a fixing nut, The front pressing plate 4 and the rear pressing plate 5 are stuck in the rim 3, and the circumferential array of the rim 3 has blade installation holes, so as to be beneficial to arbitrarily adjust the angle of the blades. There are positioning holes, which are also conducive to clamping and fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com