Pipeline monitoring device and system based on distributed fiber sensors and acoustic wave

A distributed optical fiber and monitoring device technology, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of poor anti-interference ability and false alarm of distributed optical fiber, so as to reduce the false alarm rate and ensure safety. The performance and detection reliability are improved, and the effect of making up for the high false alarm rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

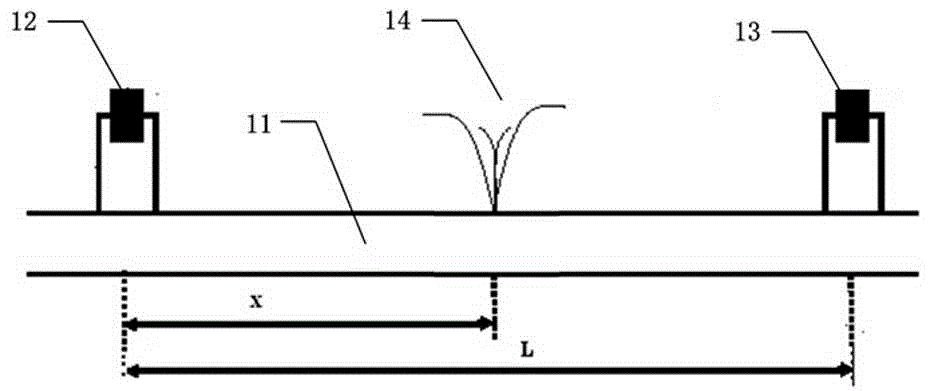

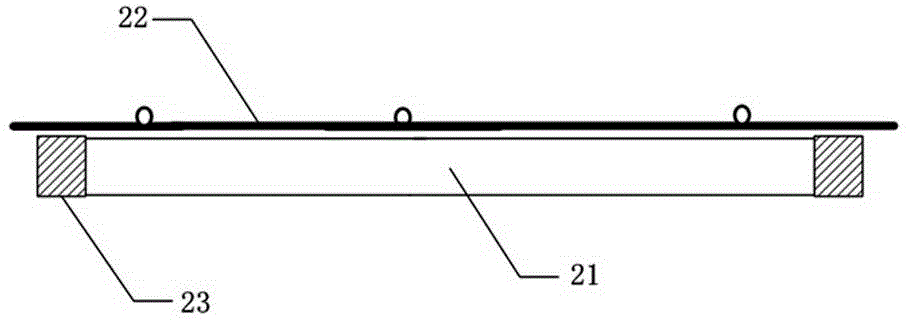

[0034] figure 2 Schematically provides a structural diagram of a pipeline monitoring device based on distributed optical fiber sensors and acoustic waves, including a pipeline 21, and a distributed optical fiber sensor 22 is laid in the monitoring area of the pipeline 21. In this embodiment, the outer wall surface of the pipeline 21 is selected Distributed optical fiber sensors 22 are laid in parallel, and acoustic wave sensing units 23 are arranged at both ends of the pipeline 21 . Of course, the distributed optical fiber sensor 22 can be installed in the vicinity of the pipeline and laid in parallel, or it can be laid on the surface of the pipeline outer wall in a spiral shape, or buried inside the pipeline outer wall, or even installed in the pipeline, or the above-mentioned several places can be selected simultaneously The distributed optical fiber sensor 22 is arranged, and the acoustic wave sensing unit 23 can also be arranged in sections on the surface of the pipe 21...

Embodiment 2

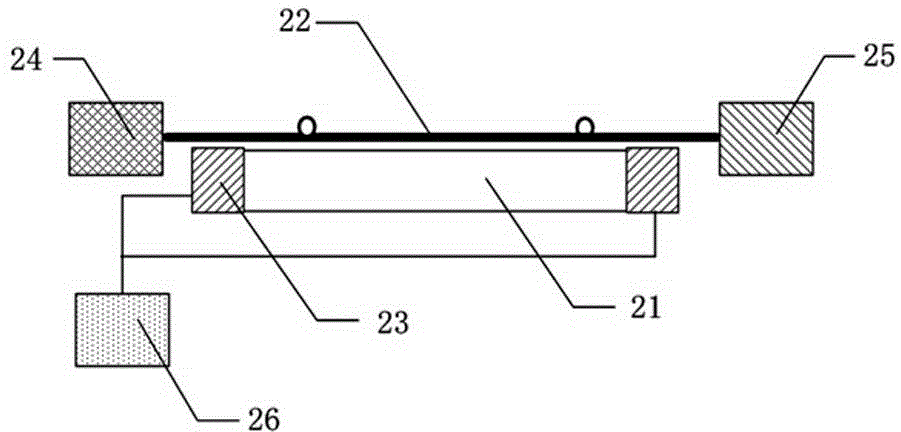

[0037] image 3 A structural diagram of a pipeline monitoring system based on distributed optical fiber sensors and acoustic waves is schematically provided, including a pipeline 21 as described in Embodiment 1, a distributed optical fiber sensor 22 laid in parallel on the outer wall surface of the pipeline 21, And the acoustic wave sensing units 23 arranged at both ends of the pipeline 21, this embodiment also includes a backscattered light detection module 24 arranged at the input end of the distributed optical fiber sensor 22, and an output optical power detection module arranged at the output end of the distributed optical fiber sensor 22 module 25, and an acoustic wave signal receiving and processing device 26 arranged at one end of the pipeline 21. The backscattered light detection module 24 completes the measurement and positioning of the static and dynamic loss of each point on the distributed optical fiber sensor, and the output optical power detection module 25 compl...

Embodiment 3

[0040] Figure 4 Schematically presents the work flow chart of the pipeline monitoring device and system based on distributed optical fiber sensors and acoustic waves of the present invention, the process includes the following steps:

[0041] Step 1: Lay distributed fiber optic sensors in the pipeline monitoring area, and install acoustic wave sensing units at both ends of the pipeline, or segmentally install acoustic wave sensing units on the pipeline, and use distributed optical fiber sensors and acoustic wave sensing units to simultaneously monitor the pipeline in real time ;

[0042] Step 2: configure the optical power detection module for the distributed optical fiber sensor; and configure the acoustic wave signal receiving and processing device for the acoustic wave sensing unit;

[0043] Step 3: When the pipeline leaks, use the distributed optical fiber sensor and the acoustic wave sensing unit to detect the leakage signal, and judge the type of leakage based on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com