Baseboard heating and cooling system

A heat dissipation system and baseboard technology, applied in heating systems, hot water central heating systems, household heating, etc., can solve problems such as difficult cleaning, easy storage of dust, large gaps, etc., to improve heat dissipation efficiency and heat dissipation , increase the contact area, improve the effect of aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

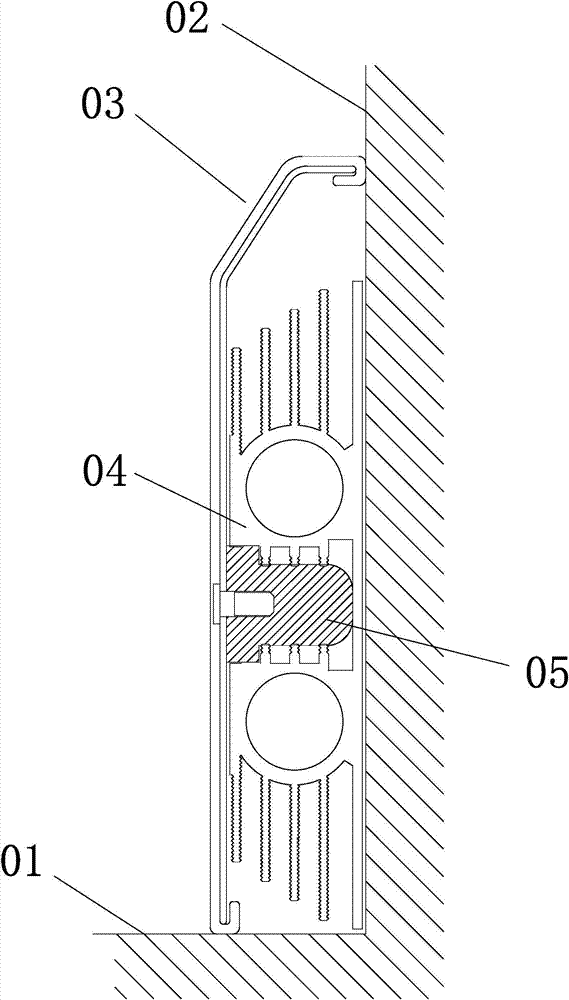

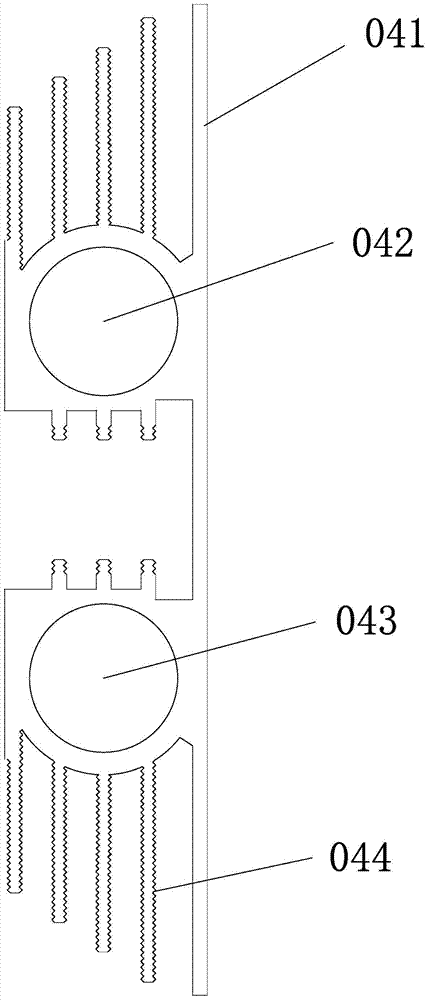

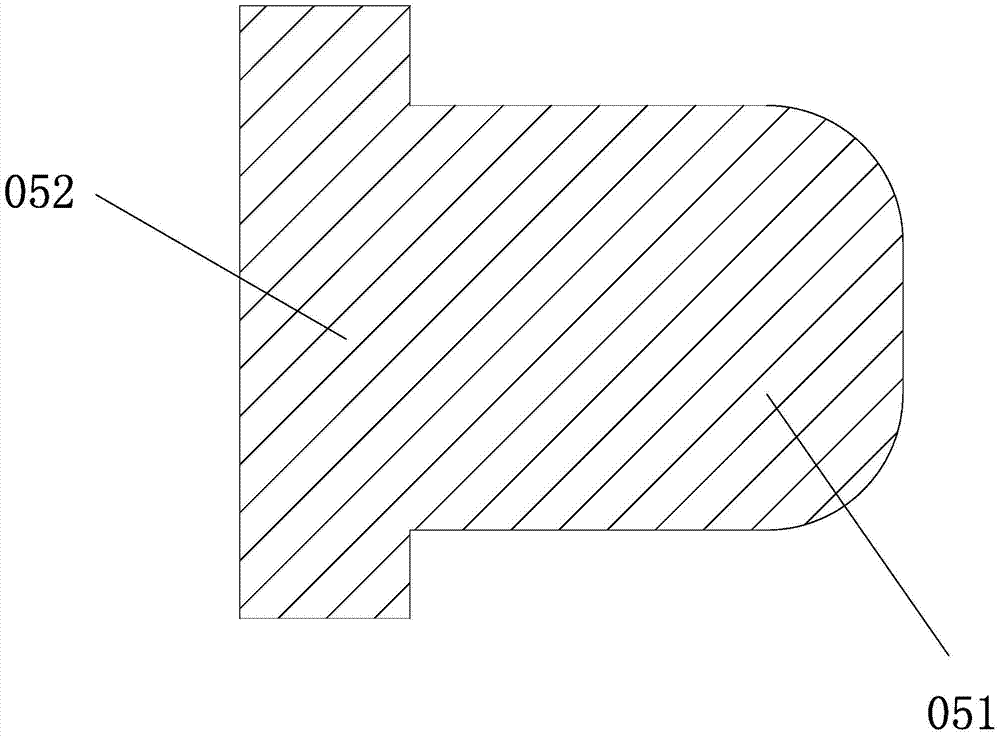

[0036] Embodiment 1: as figure 1 As shown, a skirting-type heating and cooling system includes a skirting-type heat sink 04 and a hot water supply device for heating the skirting-type heat sink. The end of the skirting-line heat sink 04 away from the wall 02 is installed with a board 03. Such as figure 2 As shown, the baseboard heat sink includes a heat dissipation plate 041 attached to the wall, and bolt mounting holes are separated on the heat dissipation plate 041, and the heat dissipation plate is connected to the wall by bolts through the bolt mounting holes. The end of the cooling plate away from the wall is integrally connected with two parallel distributed hot water pipes, the two hot water pipes are respectively the upper pipe 042 and the lower pipe 043, and the hot water pipes are located between the cooling plate and the decorative plate. The upper and lower ends of the outer wall of the hot water pipe are provided with a heat dissipation strip group integrally c...

Embodiment 2

[0038] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 14 , 15 As shown, the connecting pipe is in the shape of "U", which is used for backflow at the end of the base line. There are two parallel hot water pipes on the same base line heat sink, and the hot water is returned through the "U"-shaped connecting pipe.

Embodiment 3

[0039] Embodiment 3: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 16 As shown, the connecting pipe can also be in an "L" shape, which is used for the right-angle splicing of the inner corner or the outer corner of the cooling fin on the base line. The two ends of the connecting pipe near the middle are provided with positioning rings to ensure that the two ends of the connecting pipe are inserted into the The insertion lengths of the two ground fins are equal or even at both ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com