Heat dissipation module and centrifugal fan thereof

A centrifugal fan and cooling module technology, applied in indirect heat exchangers, non-variable-capacity pumps, lighting and heating equipment, etc., can solve the problems of reduced thickness of cooling modules, annoying noise, etc., to increase heat dissipation surface area, improve heat dissipation efficacy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following will clearly illustrate the spirit of the present invention with the accompanying drawings and detailed descriptions. After any person with ordinary knowledge in the art understands the preferred embodiments of the present invention, he can change and modify it by the technology taught in the present invention. without departing from the spirit and scope of the present invention.

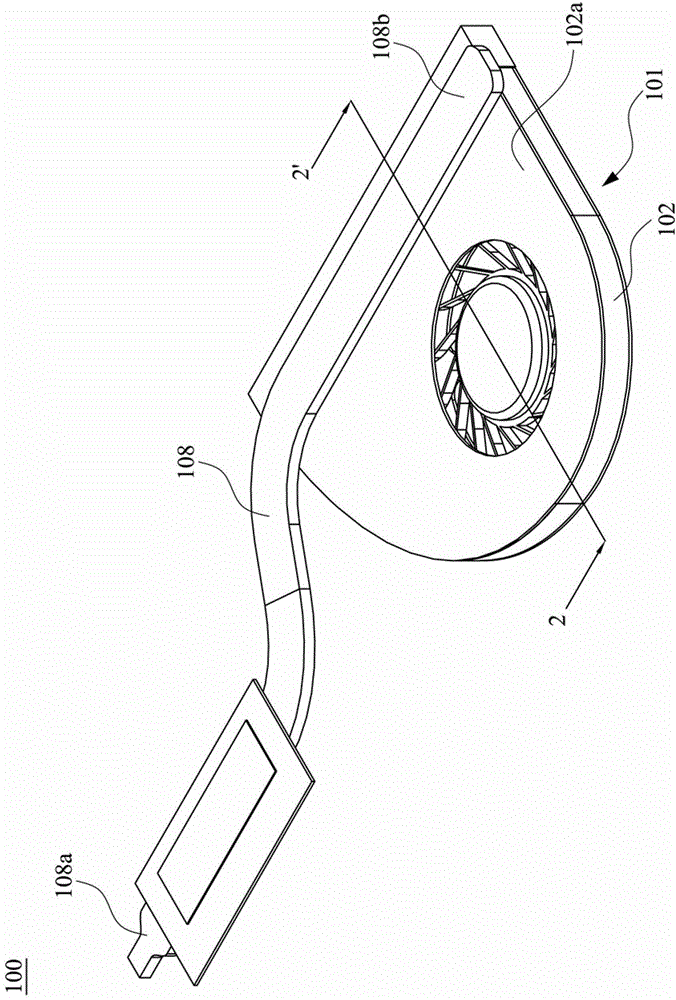

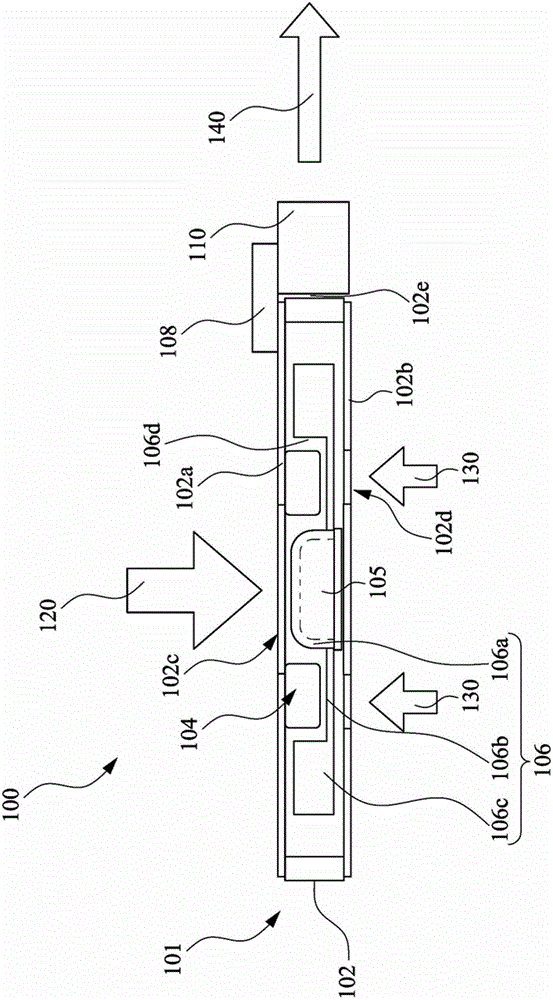

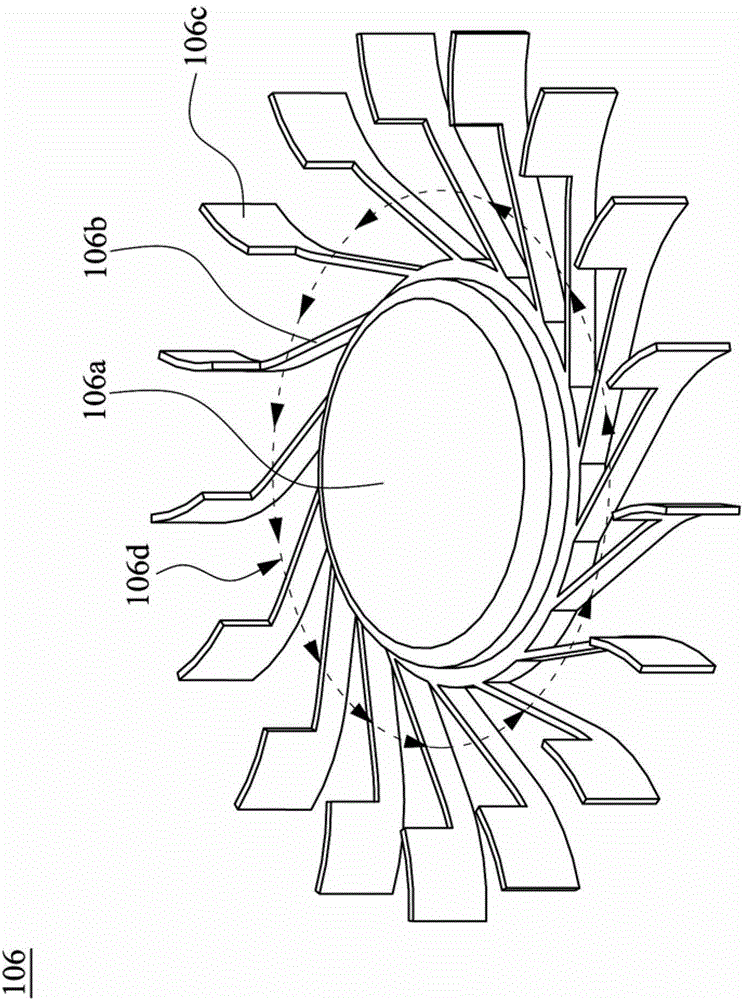

[0045] In order to solve the impact of the heat dissipation performance of the existing heat dissipation module due to thickness reduction, the present invention proposes a new centrifugal fan, in which an array of heat dissipation fins is arranged on the inner wall around the axial air inlet of the casing, and is matched with the original arrangement on the fan. Radial air outlet fin arrays are used to increase the overall heat dissipation surface area of the heat dissipation module and improve heat dissipation performance. The specific design of the cooling module equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com