Cooling fin and electric power conversion device comprising same

A technology of a heat sink and an air inlet is applied in the field of heat sinks and power conversion devices equipped with the heat sinks, and can solve problems such as increased cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

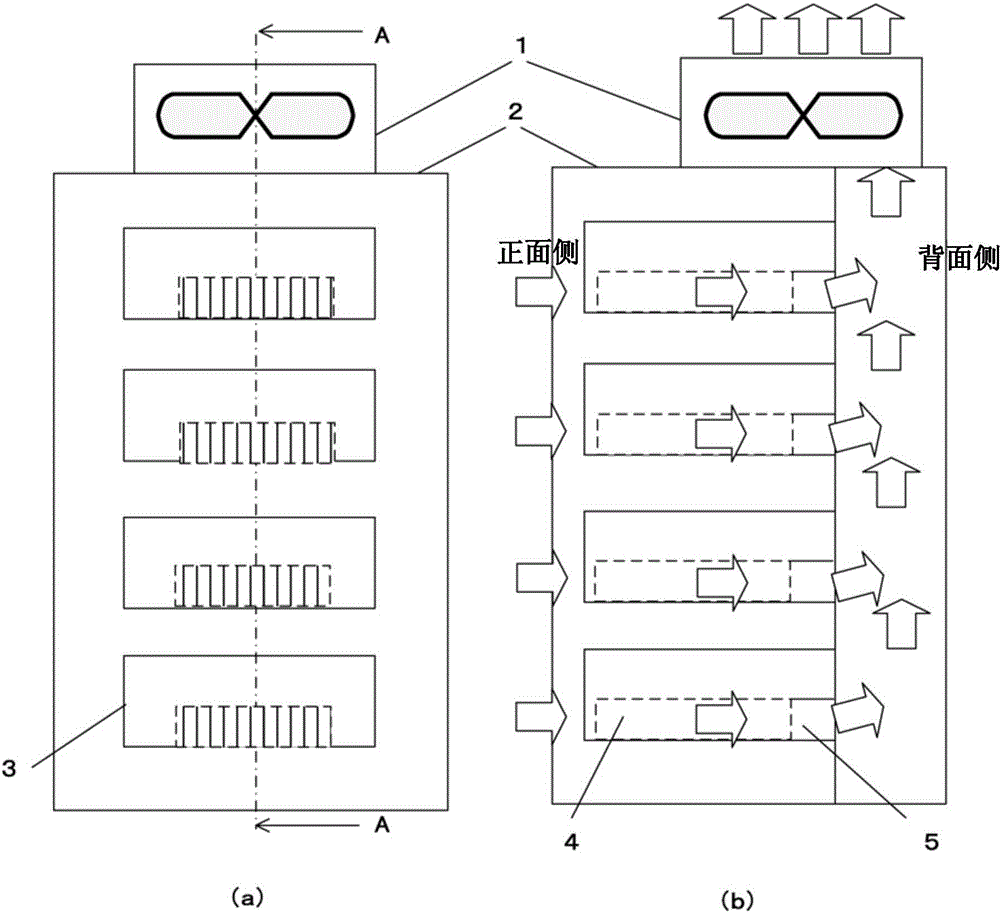

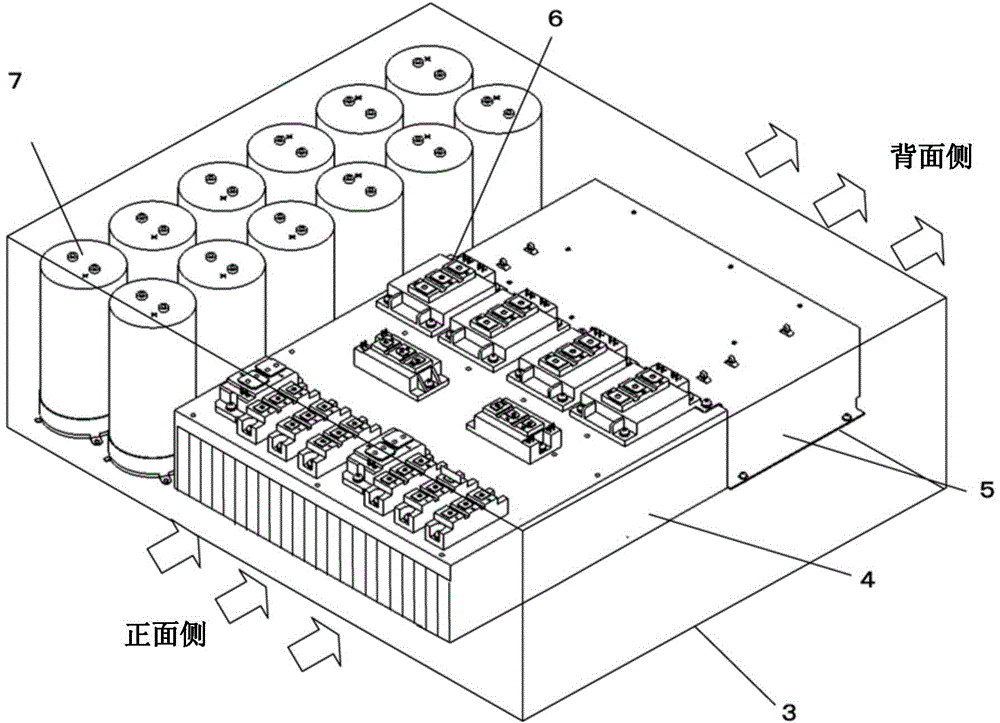

[0043] Figure 4 It is a figure which shows the structure of the heat sink of Embodiment 1 of this invention. in addition, Figure 5 It is a figure explaining the effect|action of the heat sink of Embodiment 1 of this invention.

[0044] exist Figure 4 and Figure 5 Among them, the structure of the heat sink according to Embodiment 1 of the present invention is not only provided with an air inlet on the front side of the heat sink, but also provided with a plurality of air inlets on any side or bottom in the middle from the front of the heat sink to the back of the heat sink. Inhalation port, able to inhale from all inspiratory ports at the same time.

[0045] That is, in Figure 4 (a), (b) and Figure 5In (a) and (b), on the heat sink 4, not only the air intake 8 on the front side of the heat sink is provided, but also a plurality of air intakes are provided on any side from the front of the heat sink to the back of the heat sink. 9. An air intake 10 is also provided ...

Embodiment approach 2

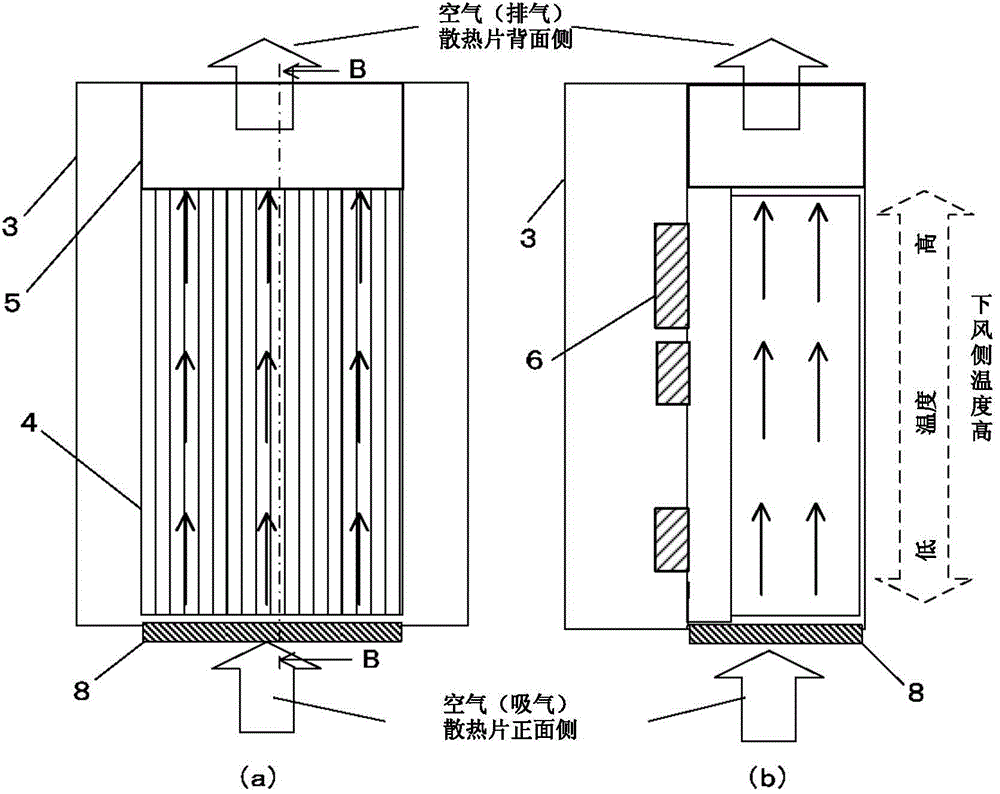

[0060] Figure 9 It is a figure which shows the structure of the heat sink of Embodiment 2 of this invention. in addition, Figure 10 It is a figure explaining the effect|action of the heat sink of Embodiment 2 of this invention.

[0061] exist Figure 9 and Figure 10 In the heat sink according to Embodiment 2 of the present invention, like the heat sink according to Embodiment 1 of the present invention described above, there are not only air inlets on the front side of the heat sink, but also any intermediate position from the front of the heat sink to the rear of the heat sink. A plurality of suction ports are newly arranged on the side or the bottom surface of the utility model, and air can be sucked from all the suction ports at the same time.

[0062] That is, in Figure 9 (a), (b) and Figure 10 In (a) and (b), a plurality of air inlets 9 are provided on any side surface from the front of the heat sink to the middle of the back of the heat sink, and a notch is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com