Method for assembling large crane bearing and ship hull

An assembly method and a crane technology, which are applied to ship components, ship construction, transportation and packaging, etc., can solve the problems of high processing precision, high processing difficulty, and high cost, and achieve the goal of ensuring normal rotation, eliminating tolerances, and reducing deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

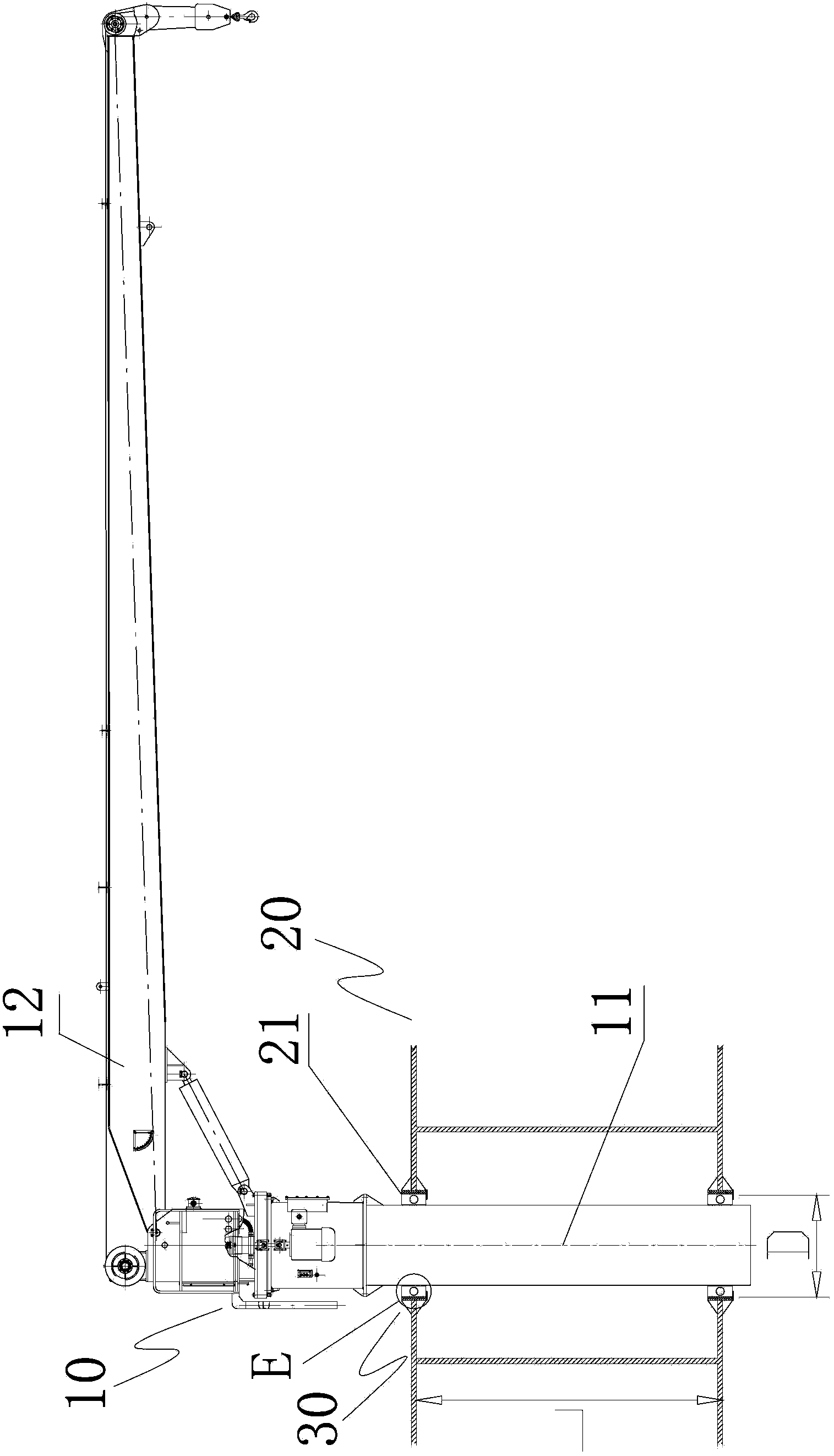

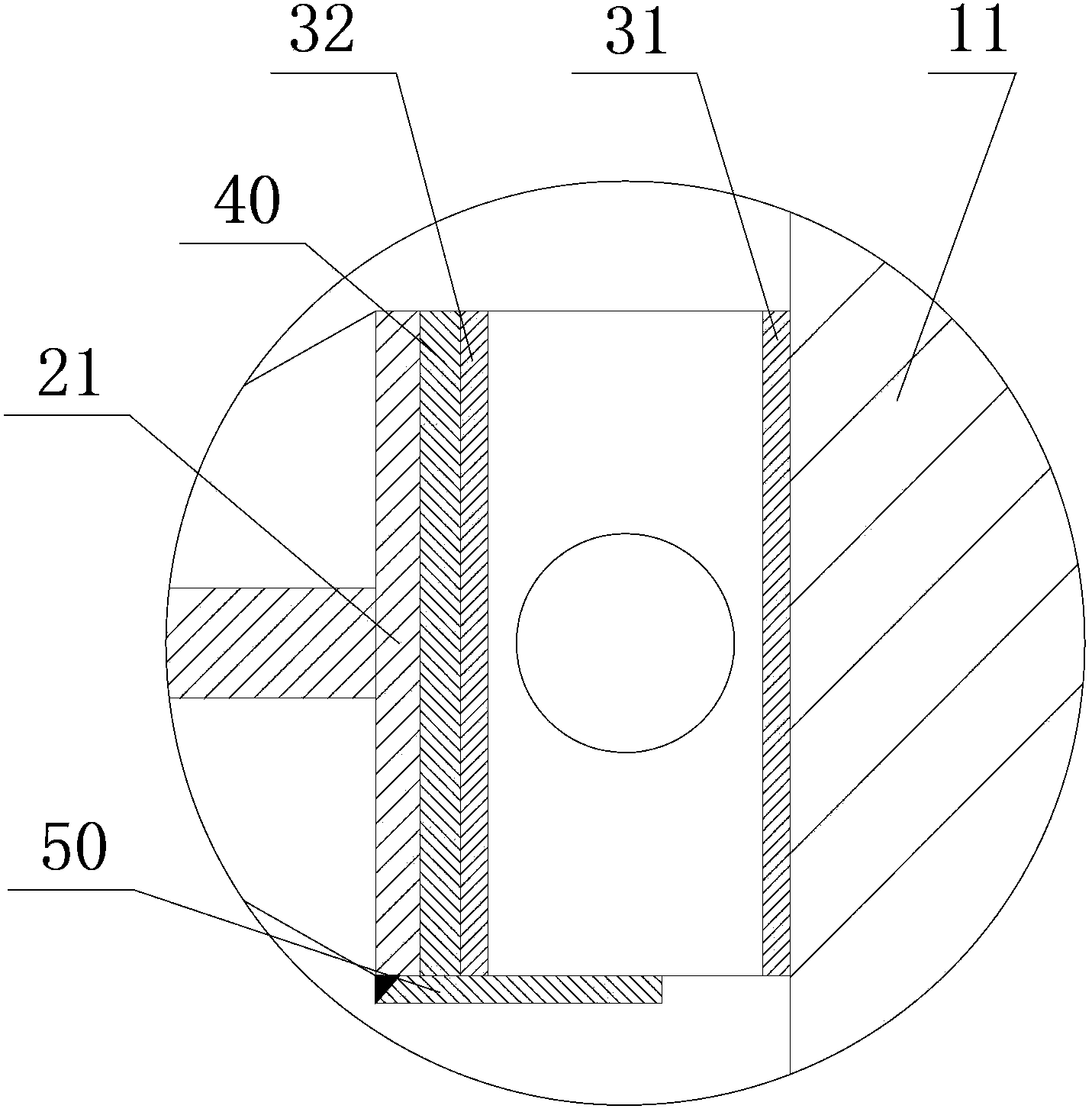

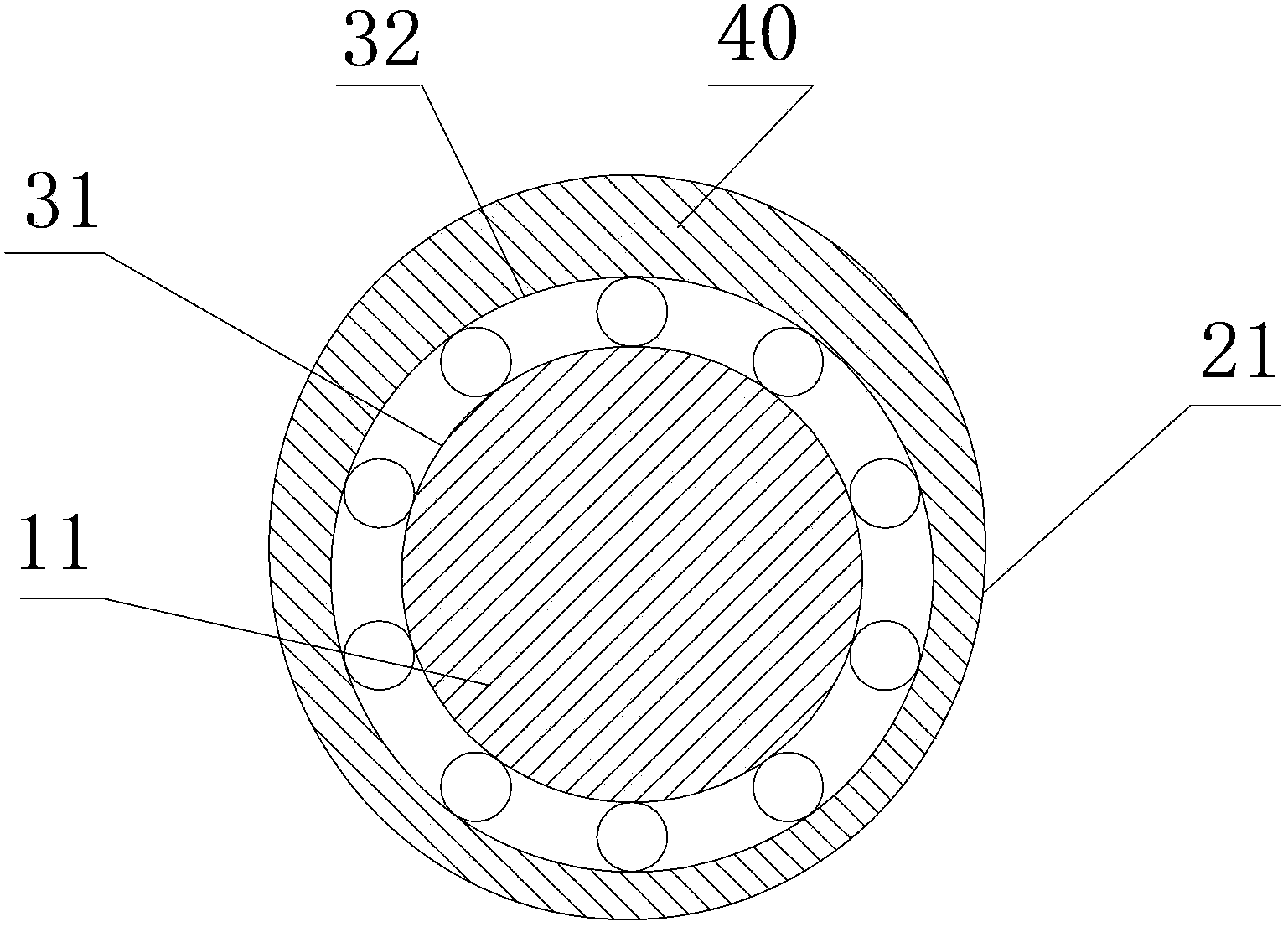

[0040] refer to Figure 1 to Figure 3 , which is a schematic diagram of the overall structure of the large crane and the hull assembled by the method for assembling the bearing of the large crane and the hull of the present invention, figure 2 for figure 1 Enlarged view of E, image 3 It is a cross-sectional view of the structure between the crane bearing and the hull assembled for the assembly method of the large crane bearing and the hull of the present invention. The large crane 10 of the present invention is installed on the hull 20 . Wherein, the large crane 10 includes a crane main shaft 11 and a boom 12 , the hull 20 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com