Foaming agent suitable for high-temperature and high-salinity oil reservoir and preparation method thereof

A high-temperature, high-salt, foaming agent technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of low evaluation of foaming agent ability, achieve strong foaming ability, good compatibility, high resistance The effect of salinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

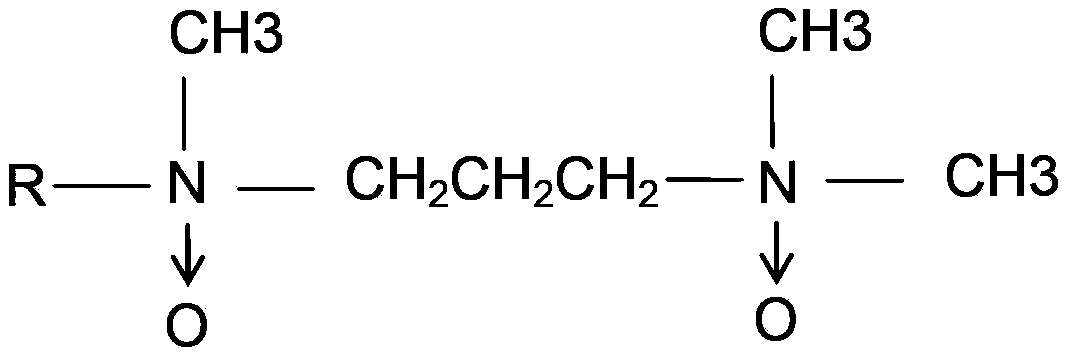

Method used

Image

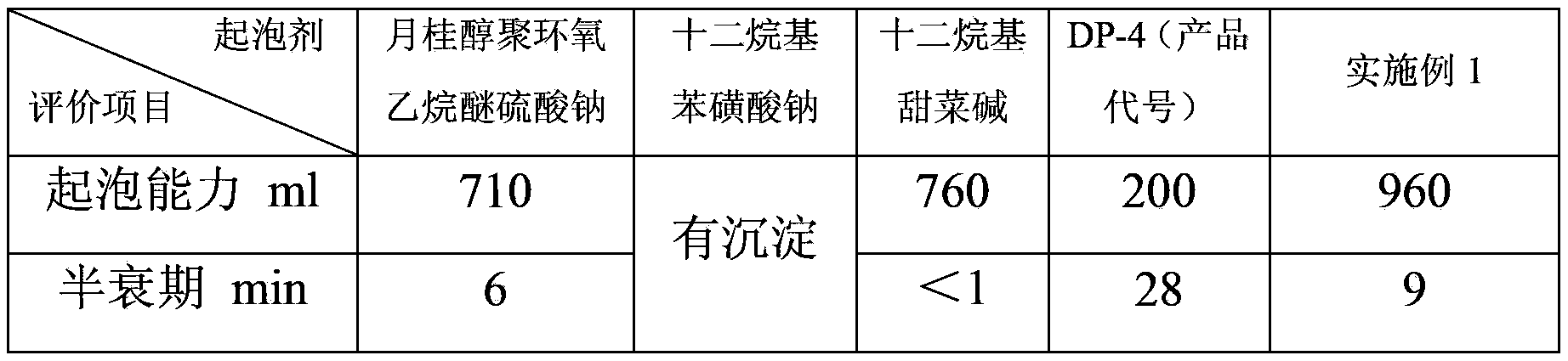

Examples

Embodiment 1

[0040] Add 300g of alkyl sulfonate (carbon number 12 to 14) into the reaction kettle, start the agitator and keep the temperature at 30°C, add 100g of distilled water while stirring, and then add 50g of foam stabilizer alkyl amine oxide (carbon number tens 2-16), adjust the pH value to 7 with hydrochloric acid, and stop heating and stirring after fully mixing. After standing and settling, the foaming agent product is obtained.

Embodiment 2

[0042] Add 150kg of alkyl sulfonate (15-16 carbons) into the reaction kettle, start the agitator and keep the temperature at 60°C, and add 30kg of foam stabilizer alkyl amine oxide (12-16 carbons) while stirring , then add 100kg distilled water, stop heating and stirring after fully mixing. After standing and settling, the foaming agent product is obtained.

Embodiment 3

[0044] Add 250g of alkyl sulfonate (carbon number 12 to 16) into the reaction kettle, start the agitator and keep the temperature at 70°C, add 100g of distilled water while stirring, then add 50g of sodium chloride, 70g of foam stabilizer alkyl oxidation Amines (carbon number 12-16), adjust the pH value to 8 with hydrochloric acid. Stop heating and stirring after fully mixing. After standing and settling, the foaming agent product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com