A washing method and washing machine using the same

A washing method and washing machine technology, applied in the field of washing machines, can solve problems such as no agitation treatment, and achieve the effects of reducing entanglement of clothes, improving washing rate, and washing evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

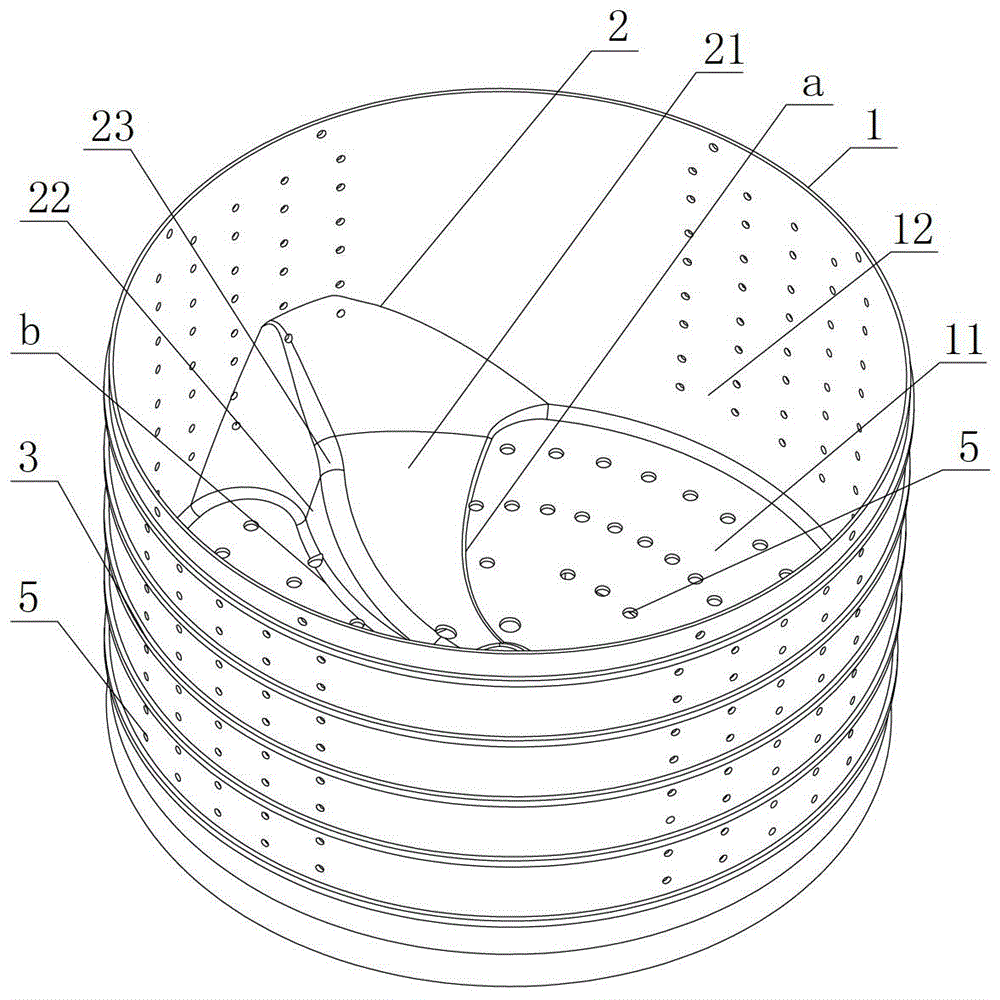

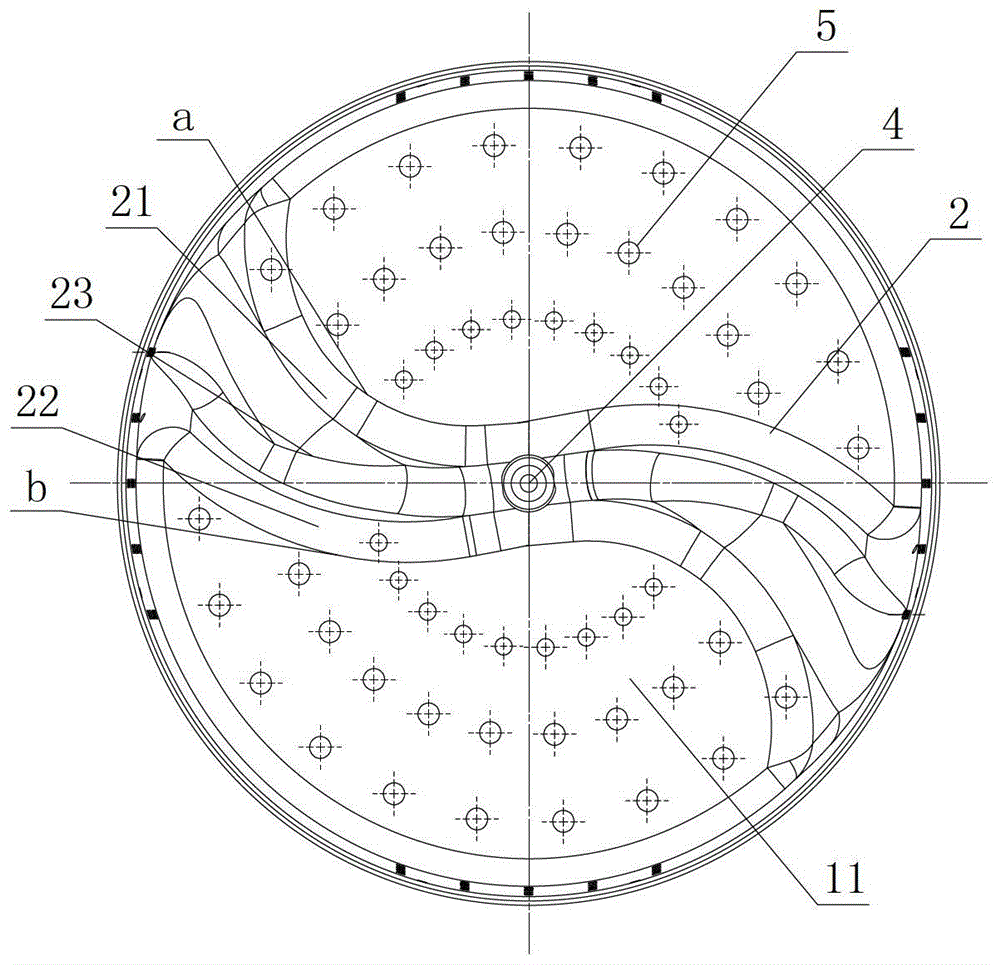

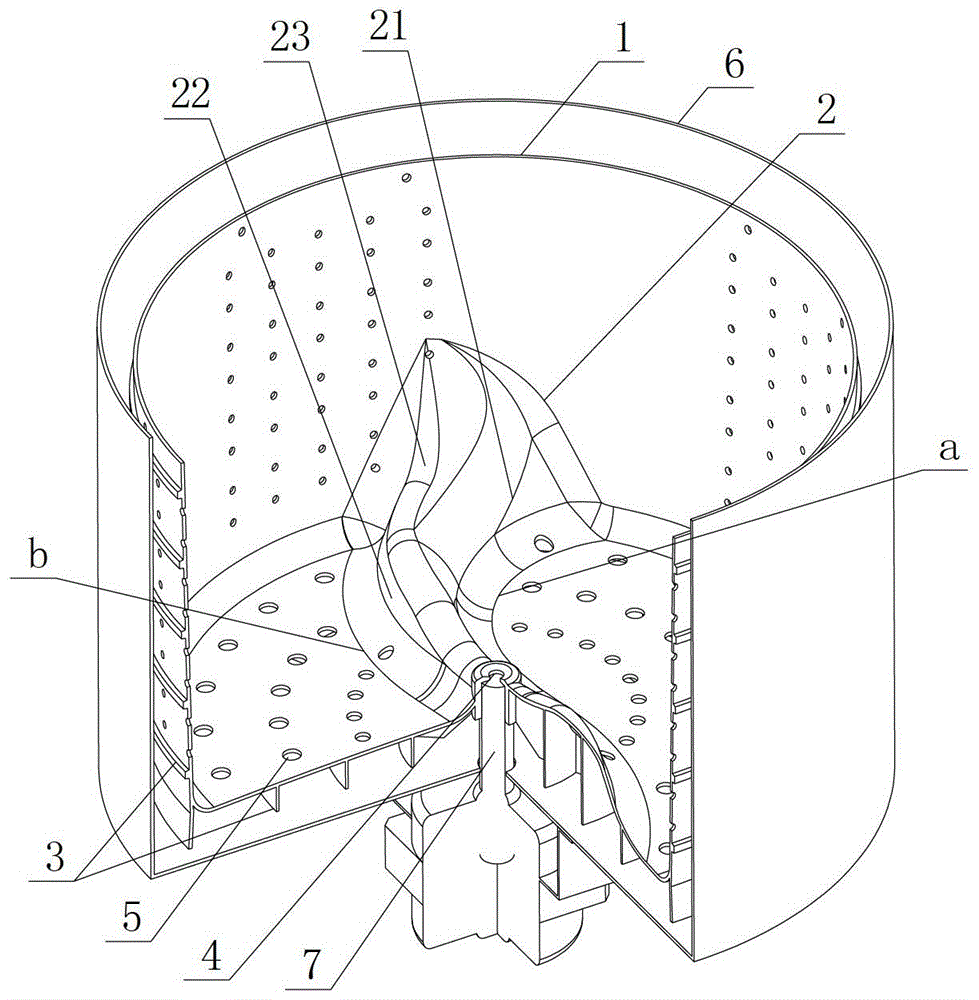

[0055] Such as figure 1 , figure 2 As shown, the integrated structure of the inner tub pulsator in this embodiment includes a vertically used inner tub 1 and a water-repellent leaf 2 at the bottom 11 of the inner tub. The water-repellent leaf 2 is integrated with the inner tub 1, and is characterized in that: The water-repelling leaf 2 is a raised structure arranged at the bottom of the inner barrel 11, and there is at least one water-repelling leaf 2, and each water-repelling leaf 2 rises and extends along the circumferential direction of the inner barrel bottom 11 and the outer direction of the barrel radial direction, and extends along the circumferential direction After reaching the highest point, it descends back to the inner barrel bottom 11 in a steep slope shape, and extends outward along the barrel radial direction to the highest point, and then connects with the inner barrel wall 12 .

[0056] That is, the water-repellent leaf 2 extends from the center of the inner...

Embodiment 2

[0070] Such as Figure 4 Shown, described washing method comprises the steps:

[0071] 1) Put the detergent together with the clothes into the washing inner tub, if necessary, add softener at the same time, and start the washing machine;

[0072] 2) Control the washing inner tub to rise to the forward rotation speed X at a certain acceleration, rotate forward for a certain time T1, pause for a period of time, then increase to the reverse rotation speed Y at a certain acceleration, and rotate reversely for a certain time T2. The angle is not equal to the angle of each reversal, and the process is repeated 30 times. The forward rotation speed X and the reverse rotation speed Y are respectively 20 to 100 rpm, and the forward rotation time T1 and the reverse rotation time T2 are respectively 1~5s, and X×T1>Y×T2, take forward rotation speed X and reverse rotation speed Y as 50rpm, forward rotation time T1 and reverse rotation time T2 are 3s and 2s respectively;

[0073] 3) Enter ...

Embodiment 3

[0078] Such as Figure 4 Shown, described washing method comprises the steps:

[0079] 1) Put the detergent together with the clothes into the washing inner tub, if necessary, add softener at the same time, and start the washing machine;

[0080] 2) Control the washing inner tub to rise to the forward rotation speed X at a certain acceleration, rotate forward for a certain time T1, pause for a period of time, then increase to the reverse rotation speed Y at a certain acceleration, and rotate reversely for a certain time T2. The angle is not equal to the angle of each reversal, and the process is repeated 30 times. The forward rotation speed X and the reverse rotation speed Y are respectively 20 to 100 rpm, and the forward rotation time T1 and the reverse rotation time T2 are respectively 1~5s, and X×T1

[0081] 3) Enter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com