Method for well cementation drilling-free blind plate circulating well cementation of horizontal well

A technology for horizontal wells and cementing, which is used in wellbore/well components, earthmoving, sealing/packaging, etc., can solve the problems of easily damaged casing, long operation time, damage to tool structure, etc., and can increase the number of rubber plugs Strength, tear and damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

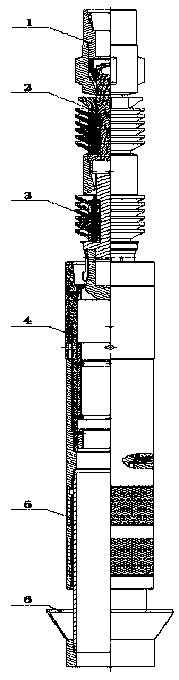

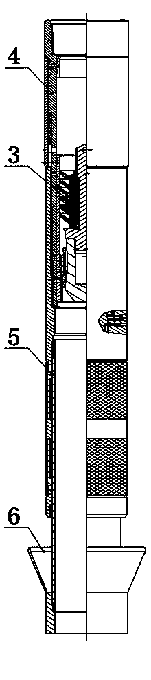

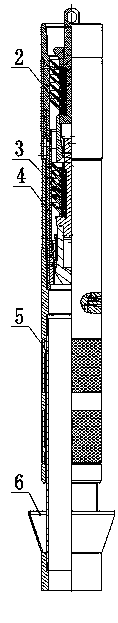

[0047] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

[0048] A drilling-free blind plate circulation cementing method for a horizontal well. The cementing method is implemented by adopting a horizontal well drilling-free blind plate circulating cementing device and changing the cementing process. The implementation method is as follows: rely on a cement umbrella 6 The body of the extended double-stage parallel seat seal casing outer packer 5 and the non-drilling plug-free step-by-step cementing device 4 without an inner pipe are organically combined to form a large-channel horizontal well drilling-free blind plate circulating cementing device. Form a circulation channel between the casing and the well wall, inject pre-fluid to wash the well wall; after cleaning the well wall, put the self-locking and retractable first-stage switch sliding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com