High-level water collecting device and wet cooling tower with same

A high-level water collection and water collection plate technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problems of shortened maintenance cycle, waste of resources, waste of power resources, etc. The effect of low water loss rate, uninterrupted heat exchange surface, and improved heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

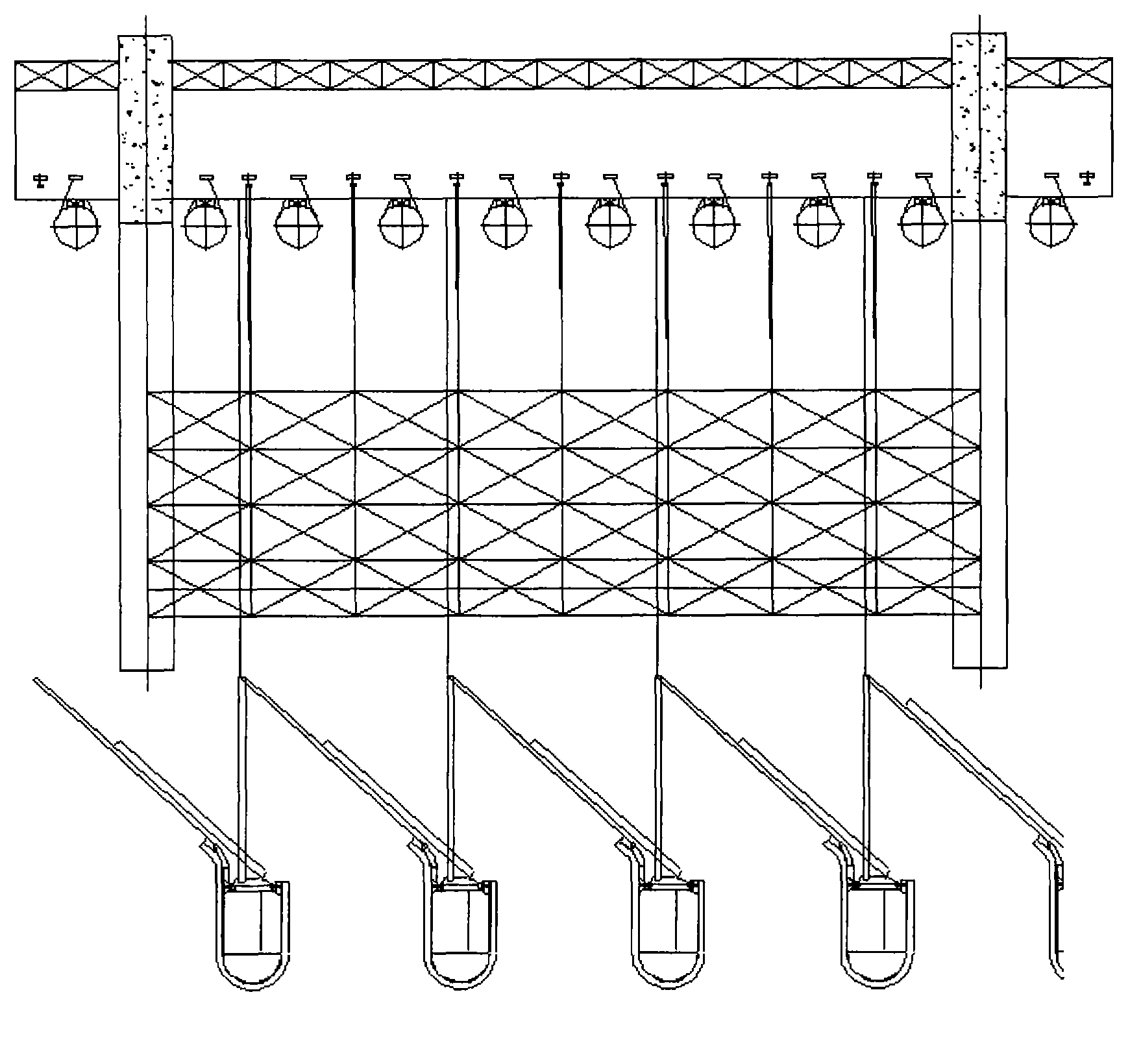

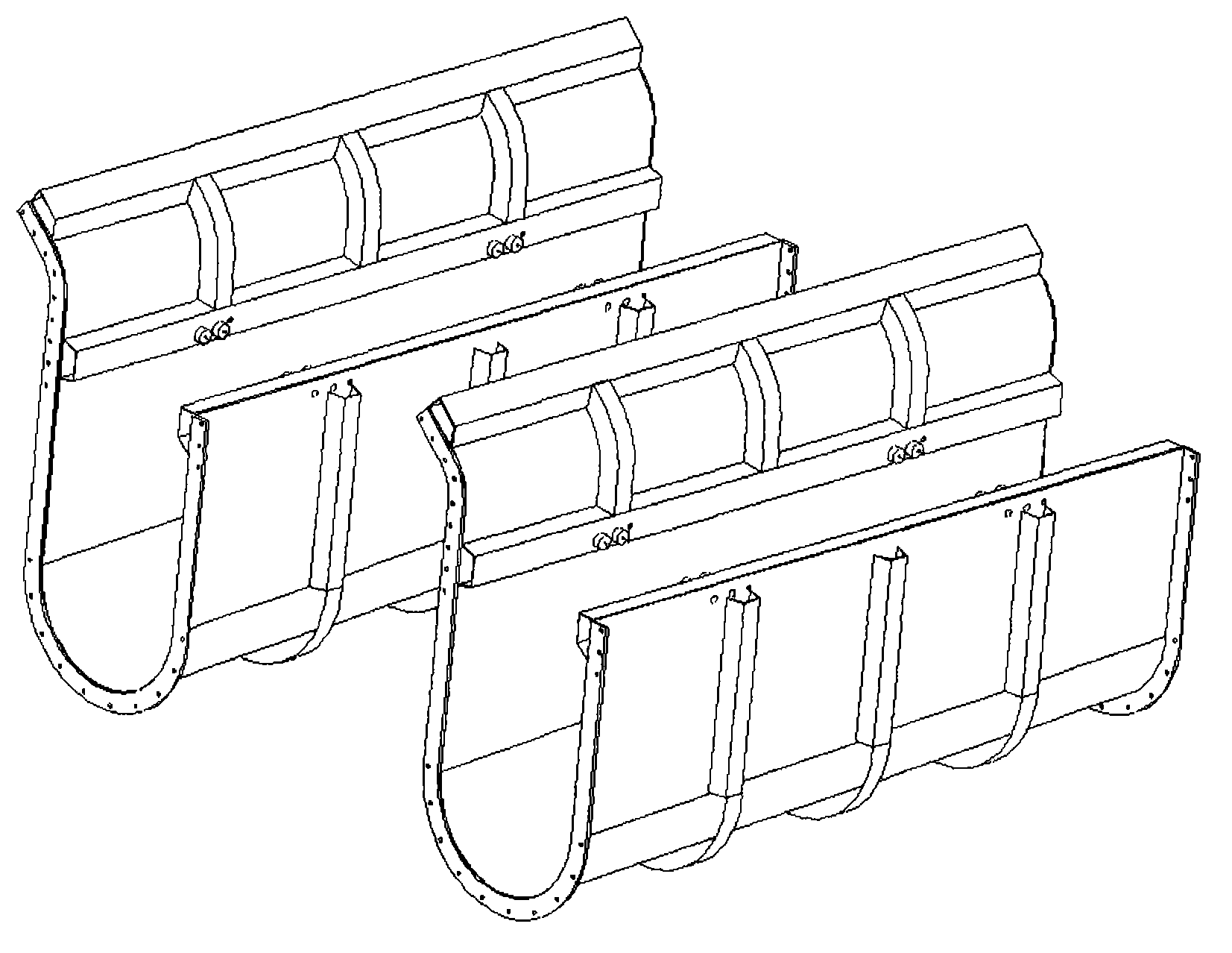

[0041] A high-level water collection device includes a plurality of water collection units arranged horizontally side by side and in parallel, and an upper water spray filler.

[0042] The high-level water collecting device also includes a horizontal stabilizing part.

[0043] The horizontal stabilizing part of the high-level water collection device is a horizontal stabilizing bar.

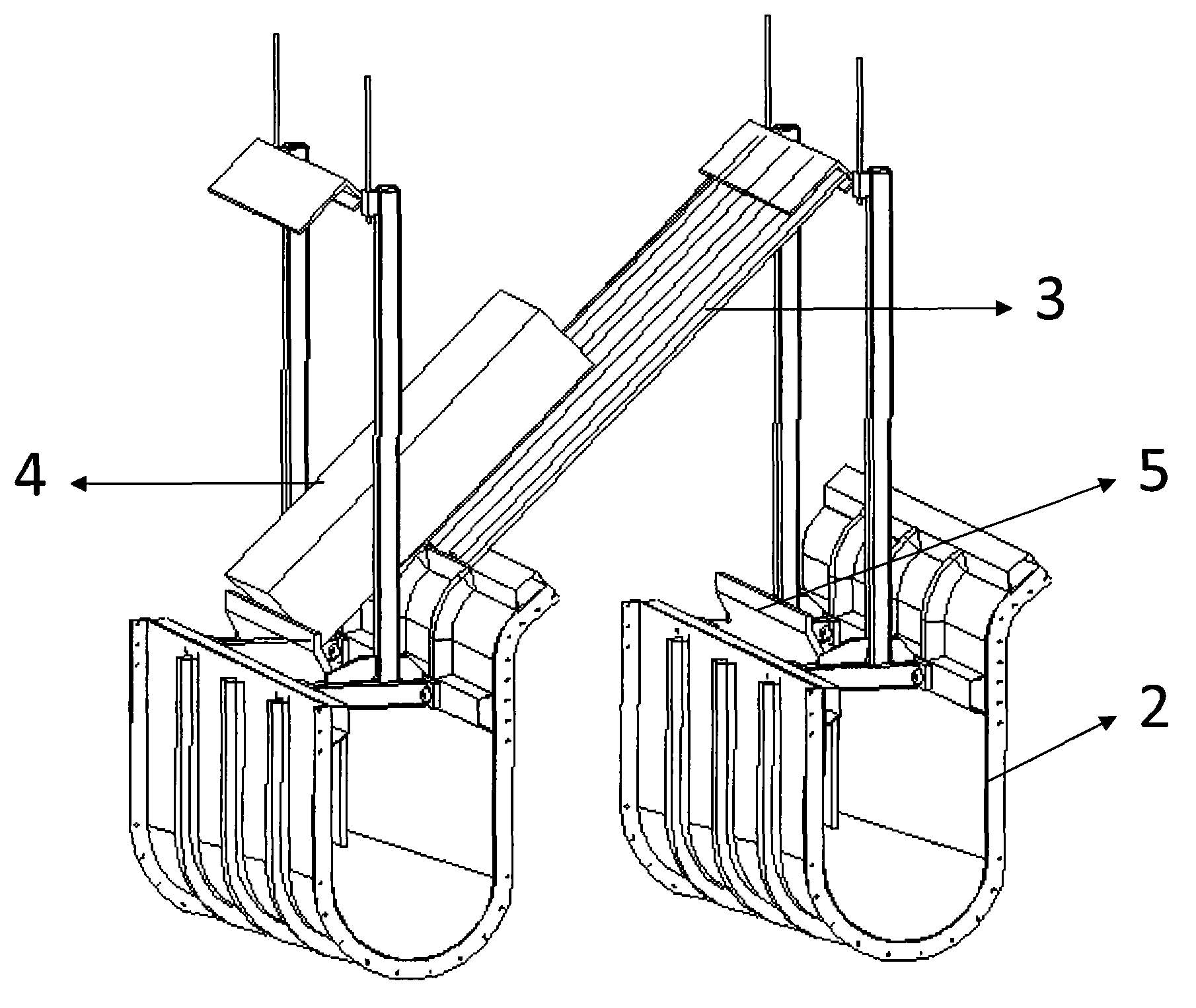

[0044] The water collection unit includes a horizontal bar, a water collection tank, a water collection plate, splash padding, and a limit plate.

[0045] The water receiving trough of the water receiving unit is a U-shaped trough, and the U-shaped troughs of each water receiving unit are horizontally arranged side by side. Both ends of the horizontal bar are provided with connecting parts to be fixedly connected to the inner wall of the U-shaped groove.

[0046] One of the mouth walls of the U-shaped mouth of the U-shaped groove extends outwards with an oblique curved plate, and the inner side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com