Manufacturing method of bamboo water collector

A manufacturing method and a water collector technology, which are applied in the field of cooling towers, can solve the problems of easy mildew, easy breakage, and short service life, and achieve the effects of small resistance coefficient, not easy to mildew, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

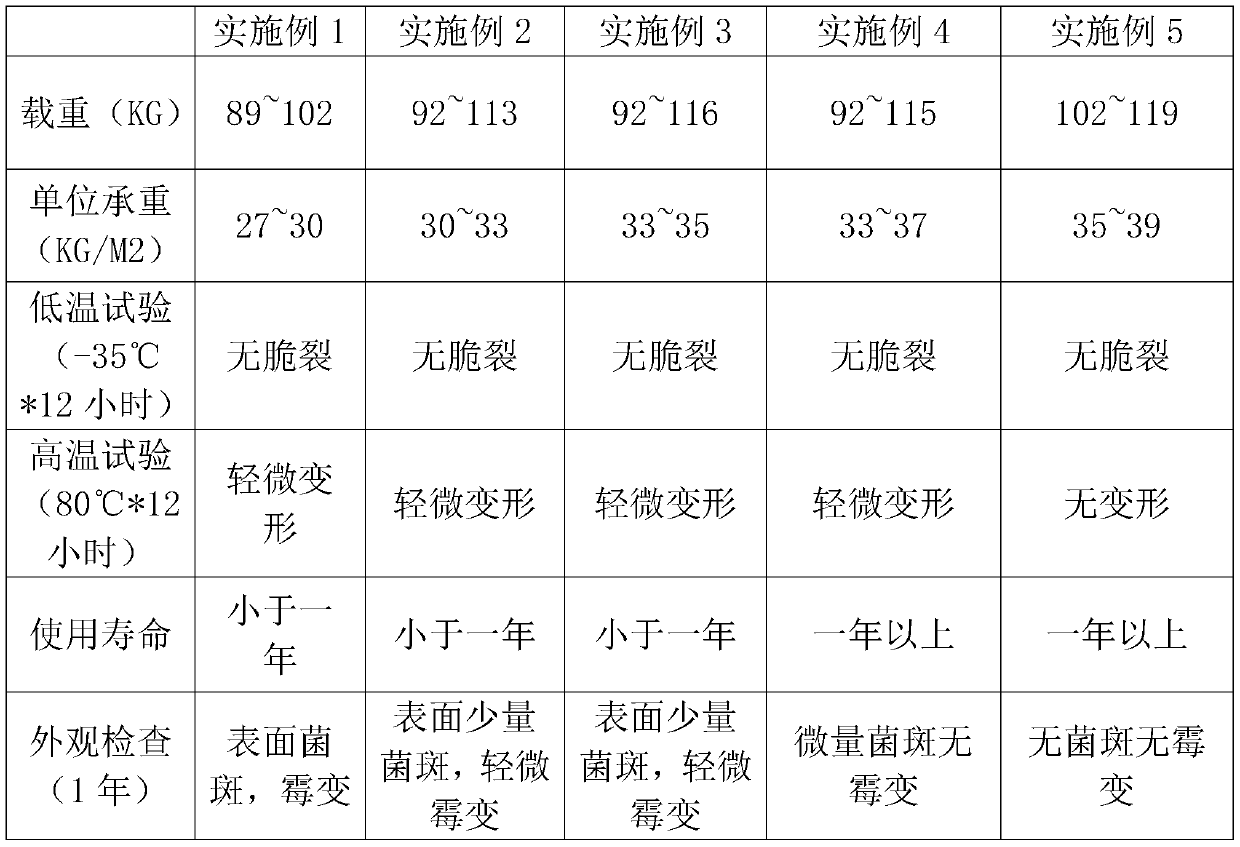

Examples

Embodiment 1

[0015] Embodiment 1 manufacture steps are as follows:

[0016] Step a: Select high-quality glass moso bamboo from Nanping, Fujian, and grow for more than 5 years in diameter The above finished bamboos are felled in autumn and winter and air-dried naturally.

[0017] Step b: select the part within 3 meters above the root as raw material.

[0018] Step c: Cut and process the parts according to the size of the drawing and assemble them, including an upper assembly and a lower assembly stacked from top to bottom. The upper assembly includes a number of first bamboo slices arranged in parallel, with at least two The bamboo boards are fixedly connected as a whole; the lower assembly includes a plurality of second bamboo slices arranged in parallel, and at least two bamboo boards are fixedly connected as a whole between the second bamboo slices. The quantity of the first bamboo slice is equal to the quantity of the second bamboo 1 minus one, and what the present embodiment adopts ...

Embodiment 2

[0020] Embodiment 2: The difference with Example 1 is that the following operations are added in the step b: after adopting 3% sodium chloride solution and 1% magnesium chloride solution to make the mixed solution in a ratio of 1:1, the raw materials are soaked in the mixed solution for at least 3 days, then dry.

Embodiment 3

[0021] Embodiment 3: The difference from Example 2 is that the following operations are added in the step b: when the moso bamboo raw material is soaked in the mixed solution in the step b, 2% quicklime is added by the mixed solution quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com