Digital coal stocktaking system and digital coal stocktaking method

A technology of coal-panning and data, which is applied in the field of digital coal-panning systems, can solve problems such as workload, coal-panning result errors, and pan-coal measuring instruments that cannot perform normal coal-panting, etc., and achieve the effect of wide scanning range, accuracy and real-time guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

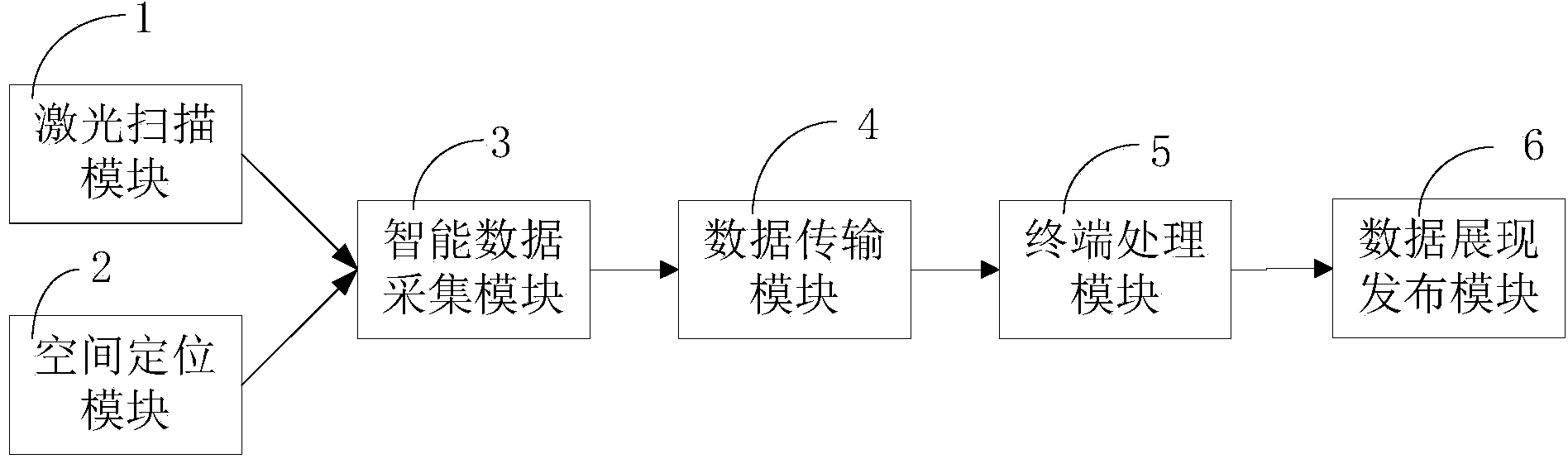

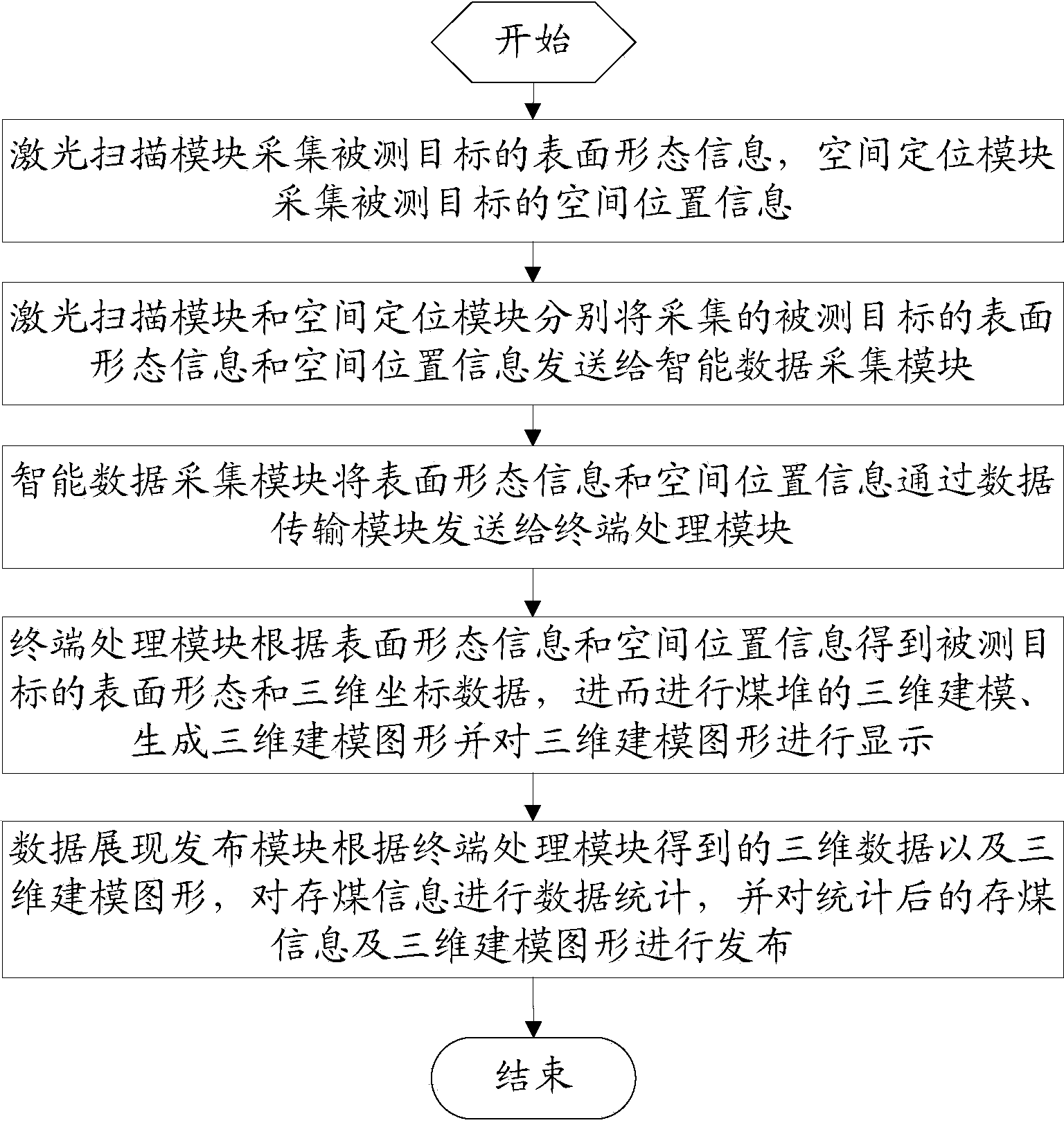

[0035] A digital coal panning system, comprising a laser scanning module 1, a spatial positioning module 2, an intelligent data acquisition module 3, a data transmission module 4, a terminal processing module 5 and a data display and release module 6;

[0036] The laser scanning module 1 and the spatial positioning module 2 are arranged on the top platform of the bucket wheel machine, the laser scanning module 1 sends the collected surface shape information of the measured target to the intelligent data collection module 3, and the spatial positioning module 2 collects the collected bucket wheel machine The spatial location information is sent to the intelligent data acquisition module 3, and the intelligent data acquisition module 3 sends the surface morphology information and the spatial location information to the terminal processing module 5 through the data transmission module 4, and the terminal processing module 5 obtains according to the surface morphology information an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com