Device, system and identification method for monitoring solid defects by multi-angle ultrasonic waves

An ultrasonic and multi-angle technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, measurement devices, and material analysis using sonic/ultrasonic/infrasonic waves, etc. problems, to achieve the effect of easy production management, small size, and wide scanning range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

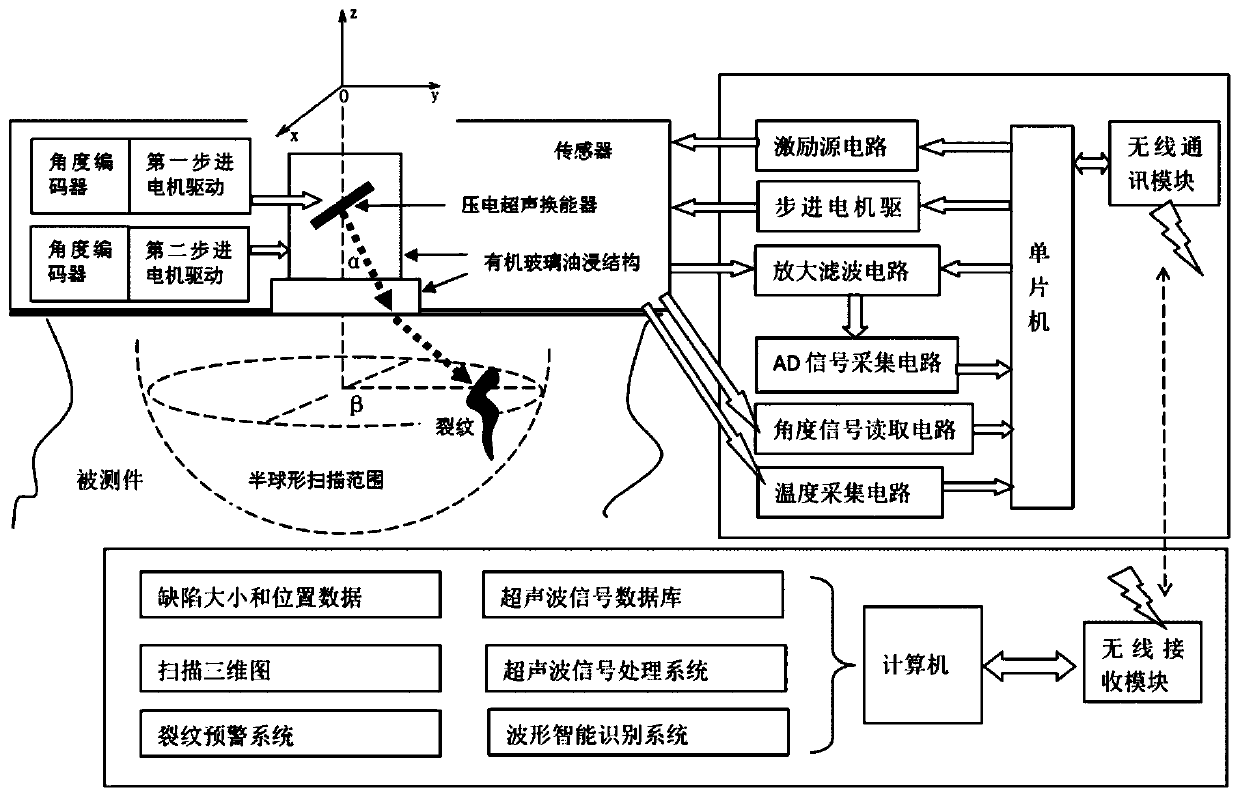

[0037] A device for multi-angle ultrasonic monitoring of solid defects, comprising a rotating block B3 immersed in oil on the installation base 1, and a rotating block A2 immersed in oil inside the rotating block B3, and the installation base 1 is provided with a first step Motor 4, the output shaft of the first stepping motor 4 is connected to the rotating block B3, the rotating block B3 is provided with a second stepping motor, the output shaft of the second stepping motor 5 is connected to the rotating block B3 The rotating block A2 is connected, and the piezoelectric transducer 10 is also arranged on the rotating block A2, and a control unit and a wireless communication module are also included, and the control unit is connected with the first stepping motor 4 and the second stepping motor respectively. The motor 5 is connected to the piezoelectric transducer 10, and the control unit is connected to the user terminal through the wireless communication module.

[0038] It i...

Embodiment 2

[0045] A system for multi-angle ultrasonic monitoring of solid defects, including a rotating mechanism, a connection module and a user processing terminal;

[0046] The rotating mechanism includes a piezoelectric ultrasonic transducer, a stepper motor and an angle encoder, the connection module includes an excitation source circuit, a stepping drive circuit, a wireless communication module and a signal acquisition circuit, and the user processing terminal Including wireless receiving module and ultrasonic data analysis system;

[0047] The user inputs instructions at the user processing terminal, drives the stepping motor on the rotating mechanism to work through the excitation source circuit in the connection module and the stepping drive circuit, and the piezoelectric ultrasonic transducer passes through the solid state to be monitored. Ultrasonic scanning is performed, and the scanned ultrasonic data is sent to the user processing terminal through the connection module, and...

Embodiment 3

[0049] A method for multi-angle ultrasonic monitoring of solid defects, comprising the following steps:

[0050] Step 1: A rotating mechanism is placed on the solid to be monitored, and the user inputs a start signal on the user processing terminal, and the user processing terminal sends an instruction to the single-chip microcomputer through the wireless module;

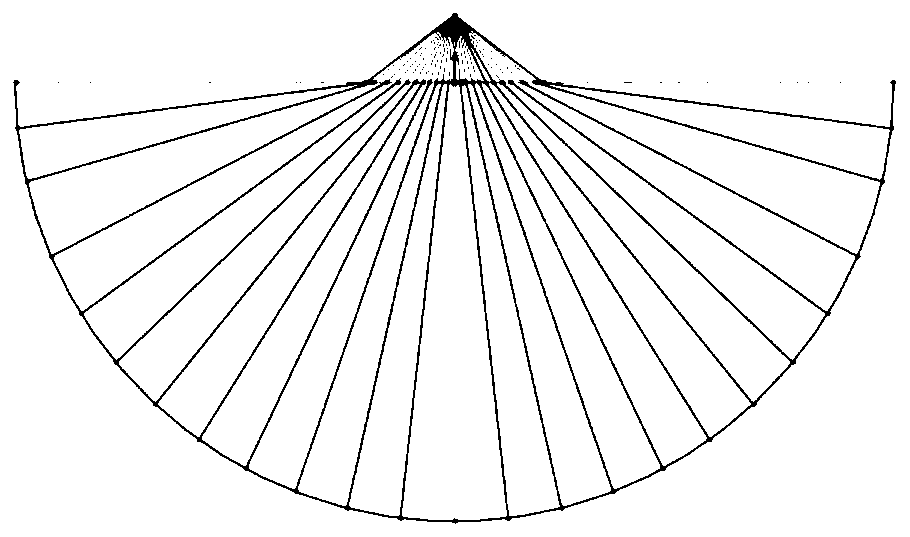

[0051] Step 2: The single-chip microcomputer controls the rotation of the rotating mechanism, the excitation source circuit on the single-chip microcomputer drives the piezoelectric ultrasonic transducer to work, and the piezoelectric ultrasonic transducer on the rotating mechanism performs ultrasonic wave while rotating. emission and ultrasonic echo collection;

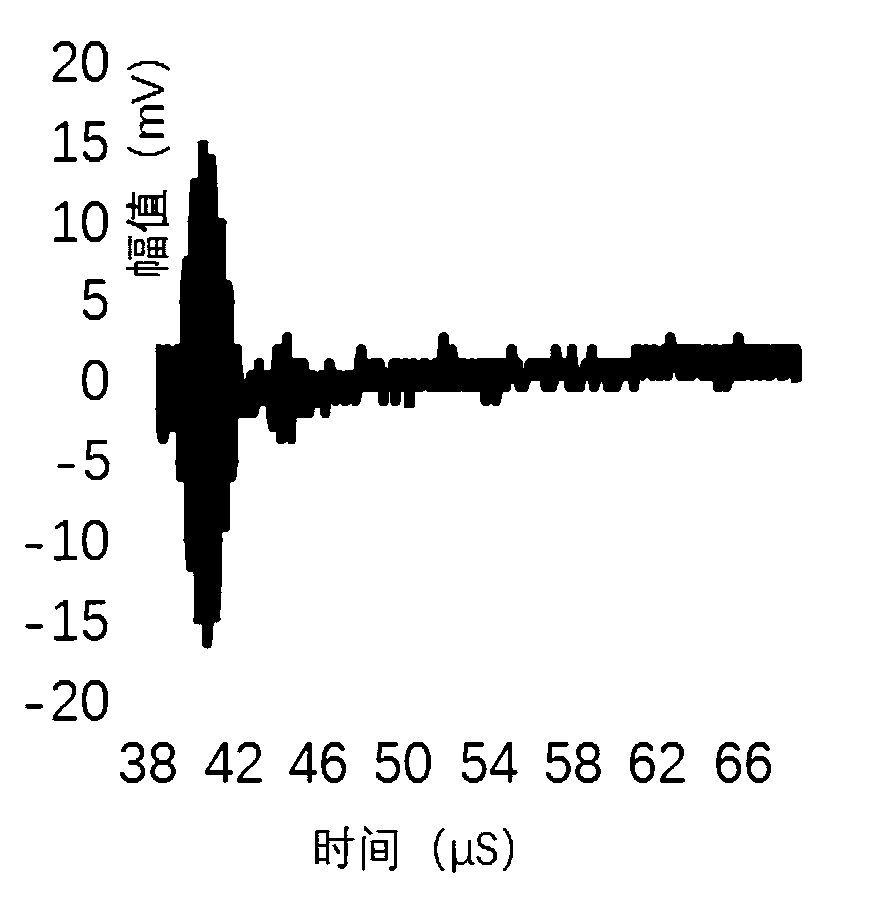

[0052] Step 3: The signal acquisition circuit on the single-chip microcomputer receives the ultrasonic echo signal and sends it to the user processing end through the wireless communication module. The user processing end processes the ultrasonic analysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com