Tube pressure simulation type shock wave detection device

A detection device and shock wave technology, applied in the direction of measuring devices, discharge tube testing, instruments, etc., can solve the problems of not being able to simulate the dynamics of xenon lamps well, and achieve the effect of stable operation and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

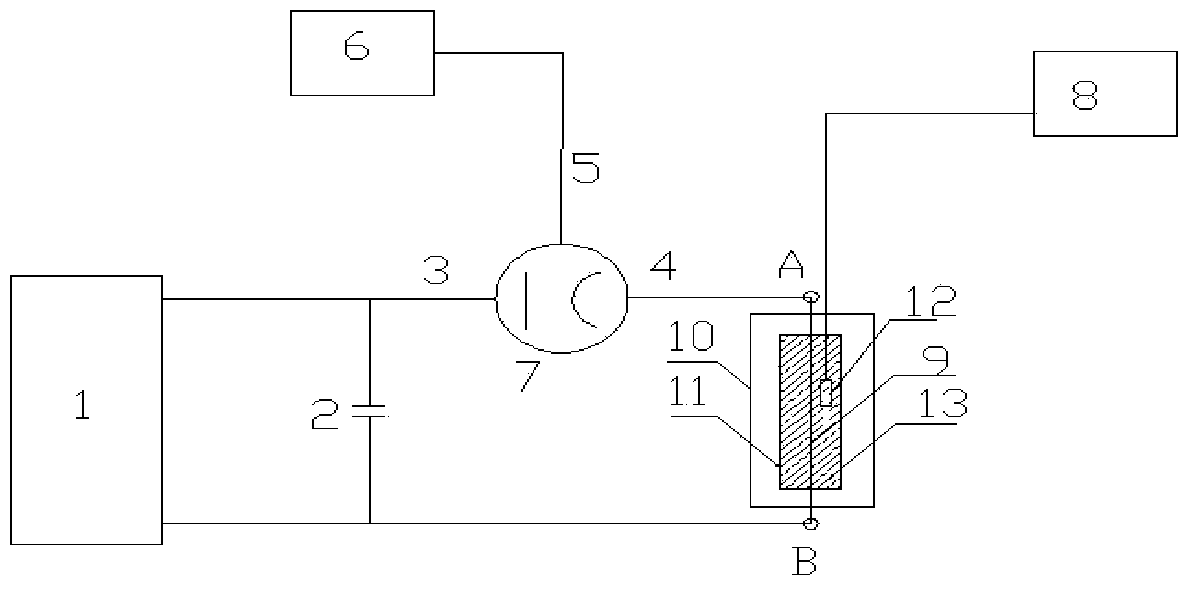

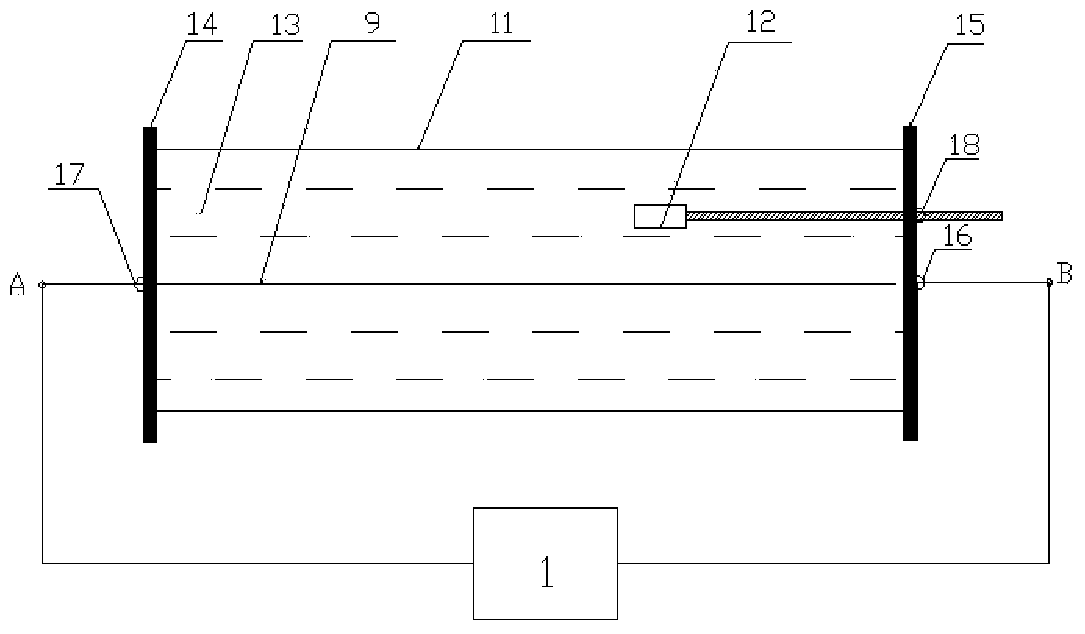

[0013] see first figure 1 , figure 1 It is a schematic diagram of the structure of the simulated lamp pressure shock wave detection device of the present invention. It can be seen from the figure that the detection device of the simulated lamp pressure shock wave of the present invention includes a switching power supply 1, a trigger 6, a pressure probe 12, a test bench 10 and an oscilloscope 8, to be tested The glass tube 11 is placed on the test bench 10, the pressure probe 12 and the metal wire 9 are housed in the glass tube 11 to be tested and filled with water 13, the positive pole of the output of the switching power supply 1 is connected to the positive pole of the capacitor 2 and the anode 3 of the ignition tube 7, the trigger pole of the ignition tube 7 is connected to the output end of the trigger 6, the cathode 4 of the ignition tube 7 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com