A Molecular Dynamics-Based Method for Measuring the Interfacial Bonding Strength of Diamond Coated Film Substrates

A technology of interface bonding strength and diamond coating, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as limitations, inability to accurately and quantitatively detect the shape of the substrate, and achieve the effect of convenient modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

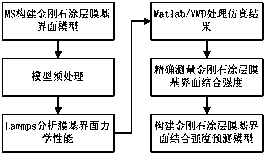

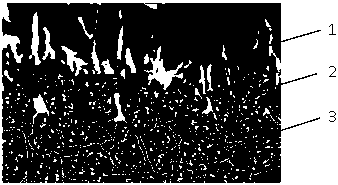

[0036] Example 1: A method for measuring the interfacial bonding strength of a diamond coating film based on molecular dynamics. Including the construction of the diamond coating film-base interface model, the molecular dynamics simulation calculation of the film-base interface, and the construction of the diamond coating film-base interface bonding strength prediction model, so as to realize the accurate quantitative measurement of the diamond coating film-base interface bonding strength, such as Figure 1 to Figure 8 Shown, the implementation of the present invention can carry out according to the following steps:

[0037] The first step: first construct the interface model of the diamond coating film base. The construction of the diamond coating film base interface model refers to the molecular dynamics modeling of the diamond coating film base interface with the help of Materials Studio software, and the establishment of a three-dimensional coordinate system in the molecul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com