Carbon fiber and glass fiber composite core type photoelectric insulation cable

A glass fiber and insulated cable technology, applied in the direction of insulated cables, power cables, insulated conductors, etc., can solve the problems of large bending radius, poor flexibility, and insufficient core strength, and achieve high strength, good flexibility, and soft texture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

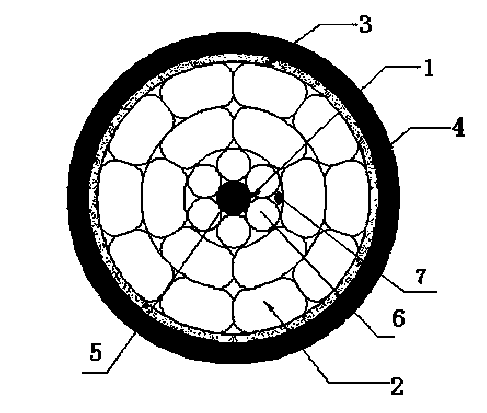

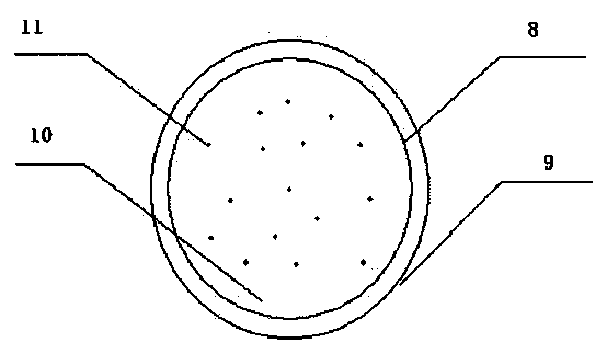

[0018] Such as figure 1 As shown, a carbon fiber and glass fiber composite core type photoelectric insulated cable, the cable uses a carbon fiber composite core 1 as a load-bearing wire core in the center, and a soft aluminum type single wire 2 is twisted outside the carbon fiber composite core 1. The soft aluminum type single wire 2 is covered with a shielding layer 3, and the shielding layer 3 is covered with an insulating layer 4; the carbon fiber composite core 1 includes carbon fiber filaments 5 and glass fiber filaments 6, and the strands of carbon fiber filaments 5 and glass After the fiber filaments 6 are twisted, they are impregnated with resin and then cured in an oven. The thickness of the shielding layer 3 is 0.6mm, the thickness of the insulating layer 4 is 3.4mm; there is one carbon fiber filament, and six glass fiber filaments. It also includes a stainless steel optical unit 7, which is accommodated in the gap between the carbon fiber composite core 1 and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap