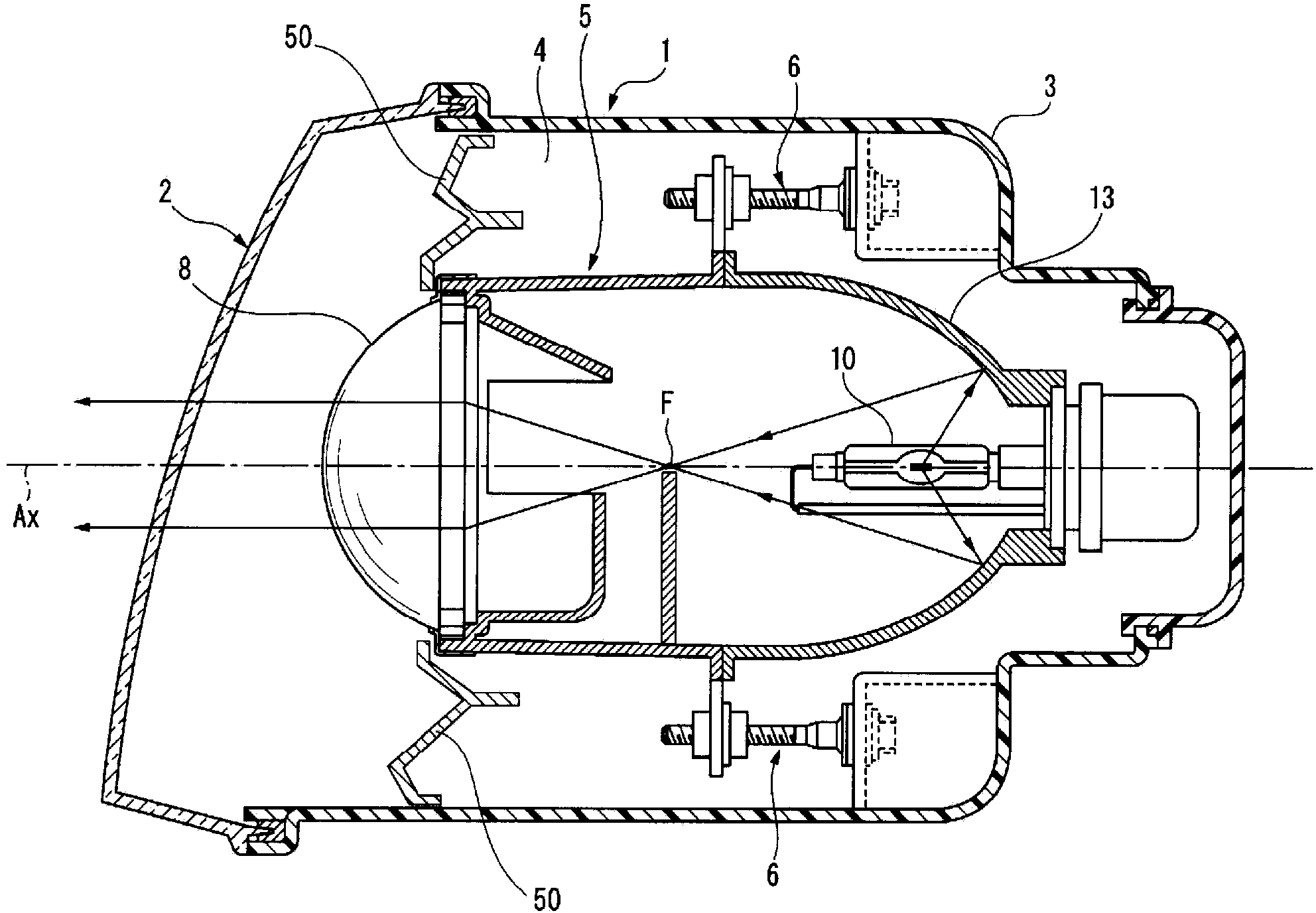

Vehicle light

A technology for lamps and vehicles, which is applied in the direction of headlights, vehicle parts, vehicle lighting systems, etc. It can solve the problems of poor adhesion between the lamp body and the front cover, peeling of the joint, etc., and achieve good adhesion and improved bonding workability , eliminate the effect of stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

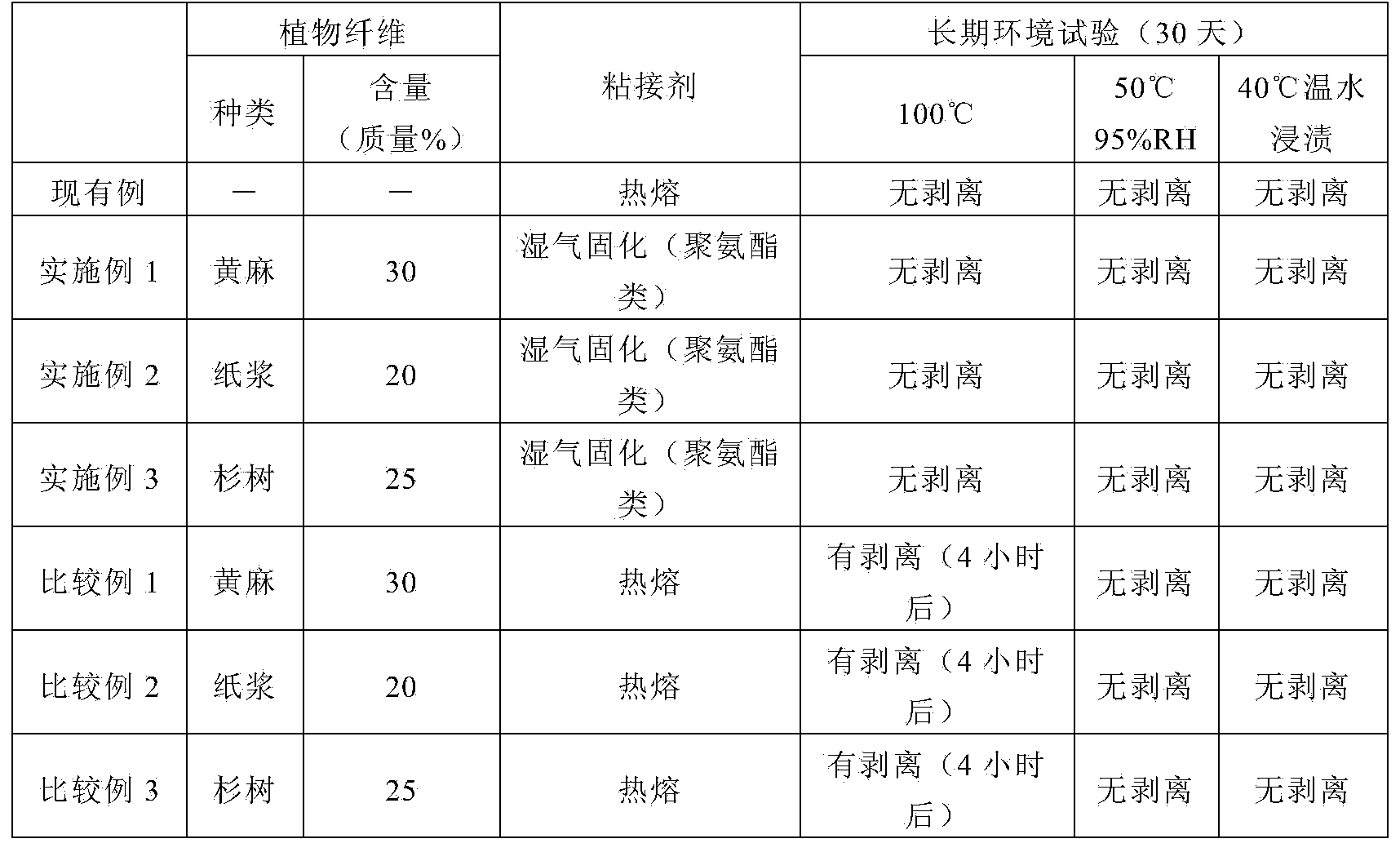

[0060] (Examples 1 to 3, Comparative Examples 1 to 3 and Conventional Examples)

[0061] (mixing and granulation of matrix resin and plant fiber)

[0062] Polypropylene (PP) was used as a matrix resin, and the plant fibers described in Table 1 below were added and kneaded so as to be the content described in Table 1 below relative to the total amount of the matrix resin and plant fibers.

[0063] After kneading, pellets with an average diameter of 3 mm and an average length of 8 mm were produced using an extrusion kneader.

[0064] (production of moldings)

[0065] After pre-drying each pellet at 90°C for 4 hours, put them into an injection molding machine (manufactured by Toshiba Machine Co., Ltd., EC40N), and perform injection molding at a cylinder temperature of 190°C and a mold temperature of 40°C. The shape is 110mm×60mm ×3mm rectangular plate test piece.

[0066] (adhesive evaluation)

[0067] After activating the bonded part of the formed plate-shaped test piece in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com