Spray gun without using air atomization slurry and slurry-spraying granulation method

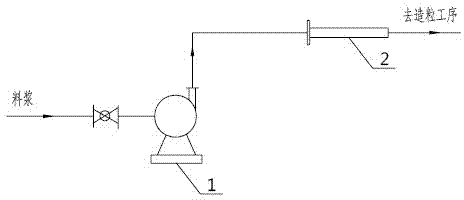

A slurry and spray gun technology, which is applied to spray devices, spray devices, liquid spray devices, etc., can solve the problems of large temperature difference between compressed air and slurry, large power consumption of air compressors, frequent equipment failures, etc. The effect of cleaning up the workload, reducing production costs, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings and embodiments, but the content of the present invention is not limited to the following embodiments.

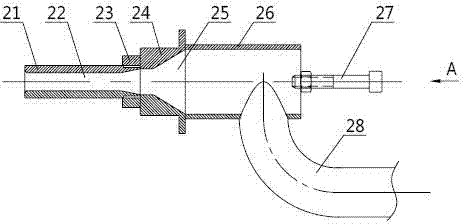

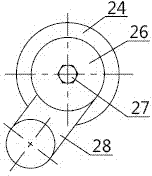

[0020] like figure 1 and figure 2 Shown, the spray gun of the present invention is a kind of spray gun that does not need to utilize air to atomize slurry, and described spray gun comprises nozzle 24, and described nozzle 24 is provided with the through hole 25 that is the shape of trumpet mouth, and the size of nozzle through hole 25 The side where the caliber port is located is welded with a spray gun branch pipe 26, and one end of the spray gun branch pipe 26 communicates with the large-diameter port of the nozzle through hole 25, and the other end is closed, and the side of the spray gun branch pipe 26 is connected with a slurry feed pipe 28. The slurry feed pipe 28 and the spray gun branch pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com