Liquid constant-temperature control device and usage method thereof

A constant temperature control, liquid technology, applied in the device and coating of the surface coating liquid, can solve the problems of endangering human health, polluting the air, increasing energy consumption, etc., to achieve a wide range of applications, reduce environmental impact, improve The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

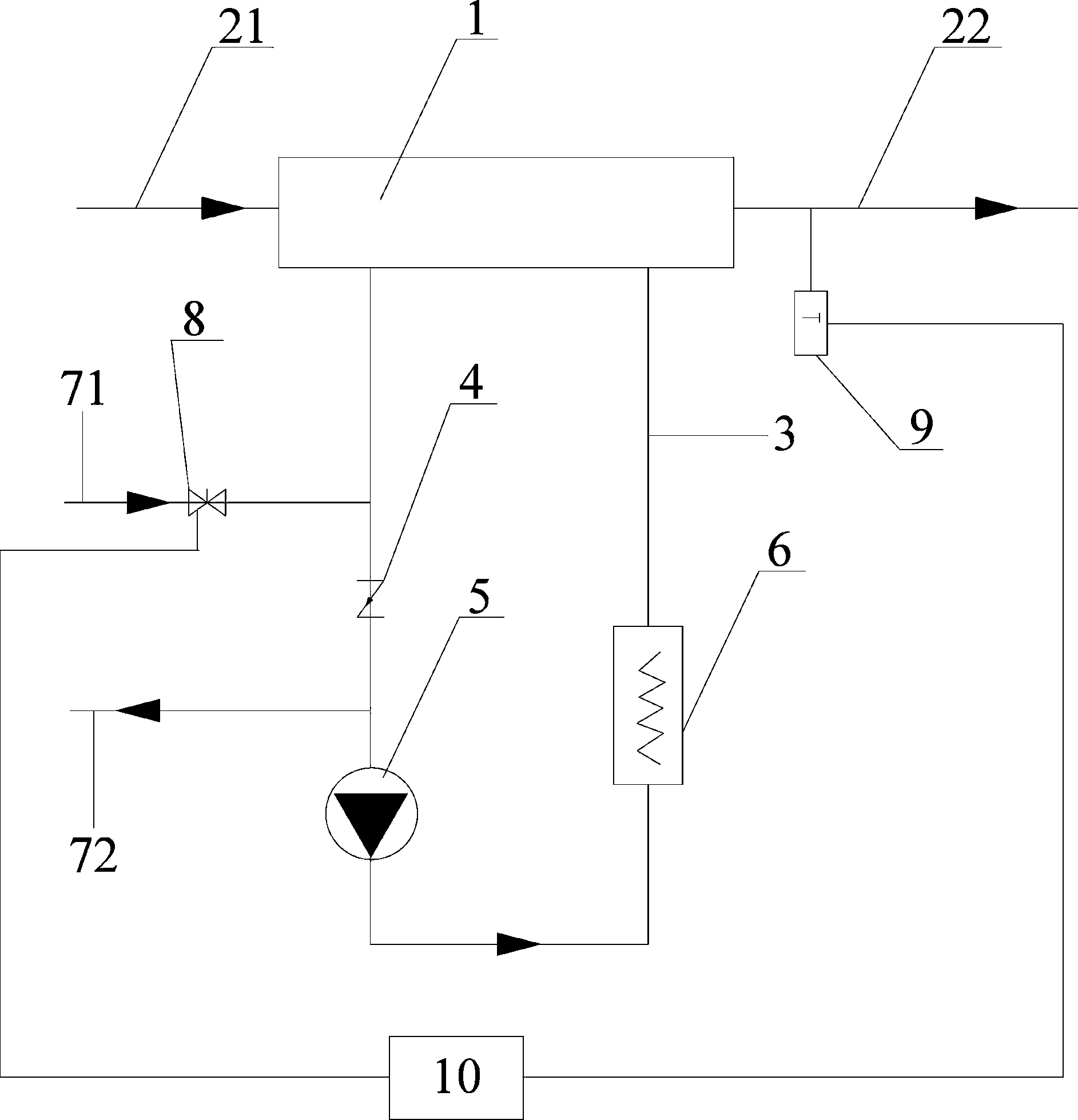

[0022] A liquid constant temperature control device, including a heat exchanger 1, an input pipe 21 and an output pipe 22, a circulating water pipe 3, a one-way valve 4, a circulating water pump 5, a heating water tank 6, a cooling water inlet pipe 71, a cooling water outlet pipe 72, Regulating valve 8, temperature sensor 9 and controller 10, such as figure 1 As shown, the specific structure is:

[0023] The inlet and outlet of the heat exchanger 1 are respectively connected to the input pipe 21 and the output pipe 22;

[0024] Both ends of the circulating water pipe 3 are respectively connected to the heat exchanger 2;

[0025] The one-way valve 4, the circulating water pump 5 and the heating water tank 6 are all connected in series on the circulating water pipe 3, and the circulating water pump 5 drives the circulating water to flow in the circulating water pipe 3 in the same direction as the permitted flow direction of the one-way valve 4;

[0026] The circulating water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com