Shielding jig structure for spraying of mobile phone antennas

A mobile phone antenna, fixing plate technology, applied in the coating, the device for coating liquid on the surface, etc., can solve the problems of slow spraying, the paint film cannot be leveled, and the object surface is unequal, and it is convenient to use and easy to process and operate. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] For further illustrating the present invention, now cooperate with accompanying drawing to elaborate:

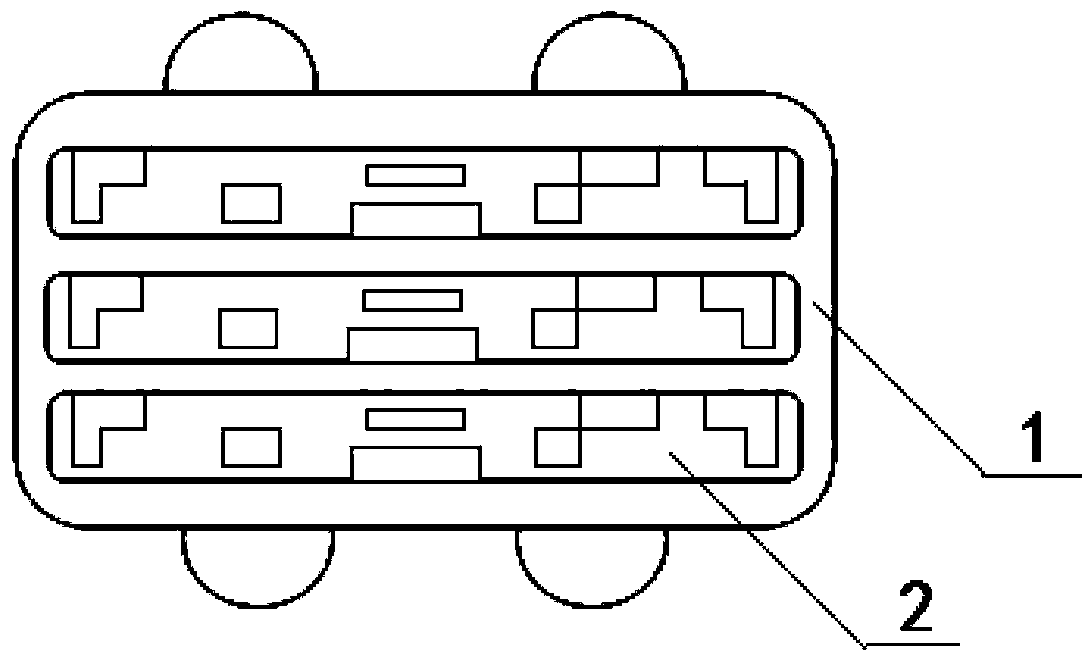

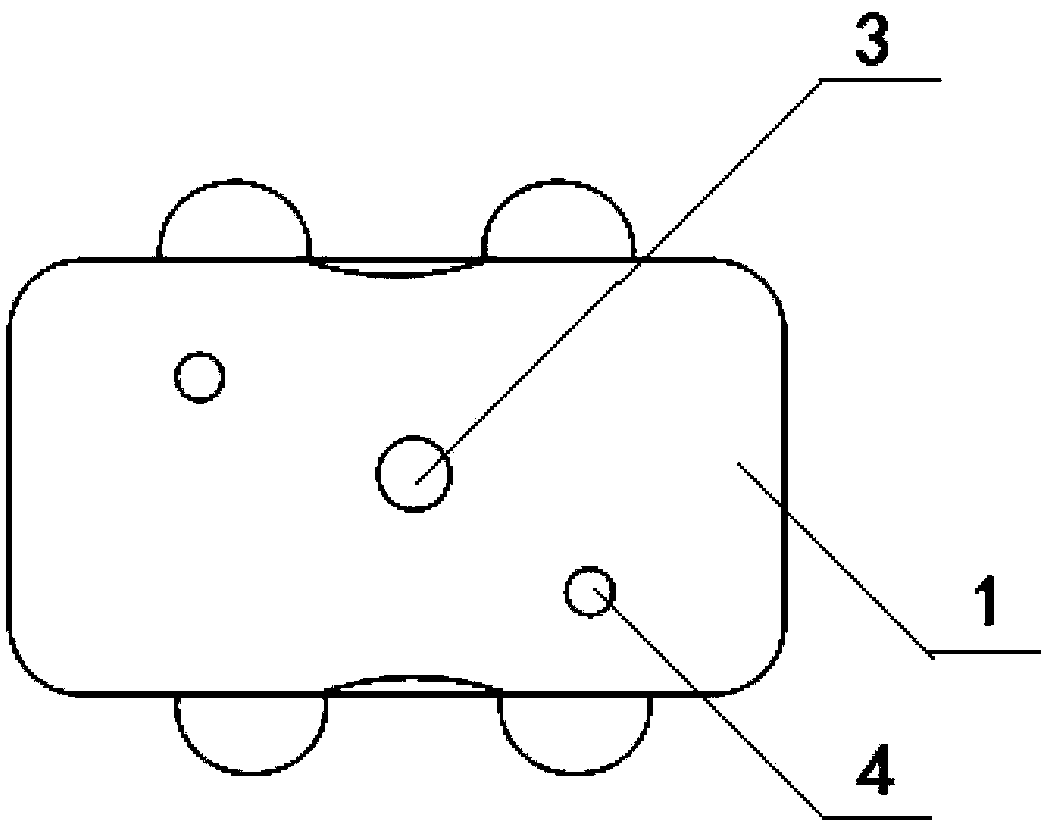

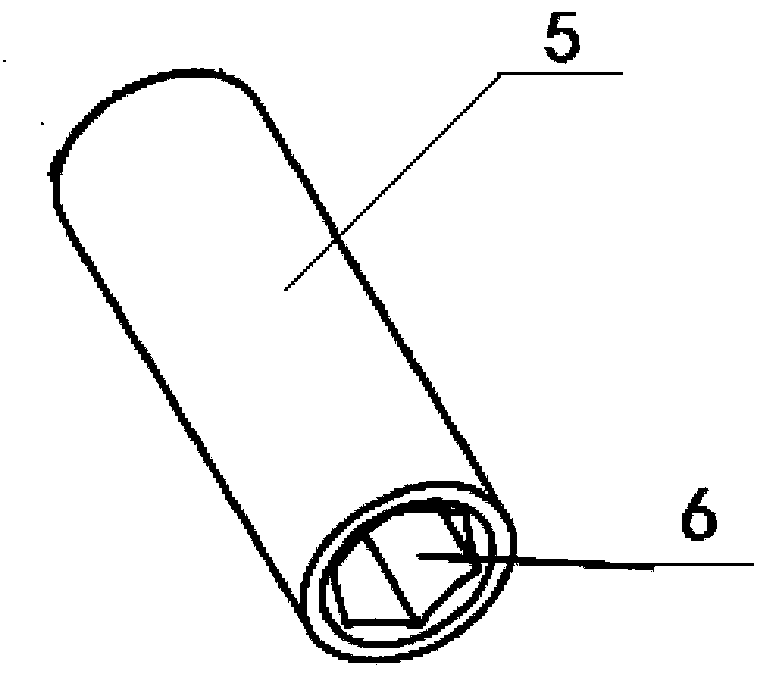

[0025] Such as Figure 1-3 As shown, the mobile phone antenna spraying shielding fixture structure is composed of a fixed plate 1 and a support rod 5. The material of the fixed plate 1 is PC material, and the inside of the support rod 5 is provided with a through hole 6. The fixed plate 1 The middle part of the bottom surface is provided with a plug-in column 3, and the plug-in column 3 is used in conjunction with the through hole 6 of the support rod 5, so that the fixed plate 1 and the support rod 5 are tightly connected by plugging, and the fixed plate 1 It is movably connected with the support rod 5, and the bottom surface of the fixed plate 1 is also provided with two locking blocks 4 for fixing with the spraying equipment, and the upper surface of the fixed plate 1 is provided with three card slots 2 for fixing the mobile phone antenna , the slot 2 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com