Improved rotor sand mold

A sand mold and rotor technology, applied in the direction of casting mold, core, casting mold composition, etc., can solve the problems of producing fine sand holes and affecting the quality of finished products, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the embodiments of the present invention will be explained and described below in conjunction with the drawings of the embodiments of the present invention, but the following embodiments are only preferred embodiments of the present invention, not all of them. Based on the examples in the implementation manners, other examples obtained by those skilled in the art without making creative efforts all belong to the protection scope of the present invention.

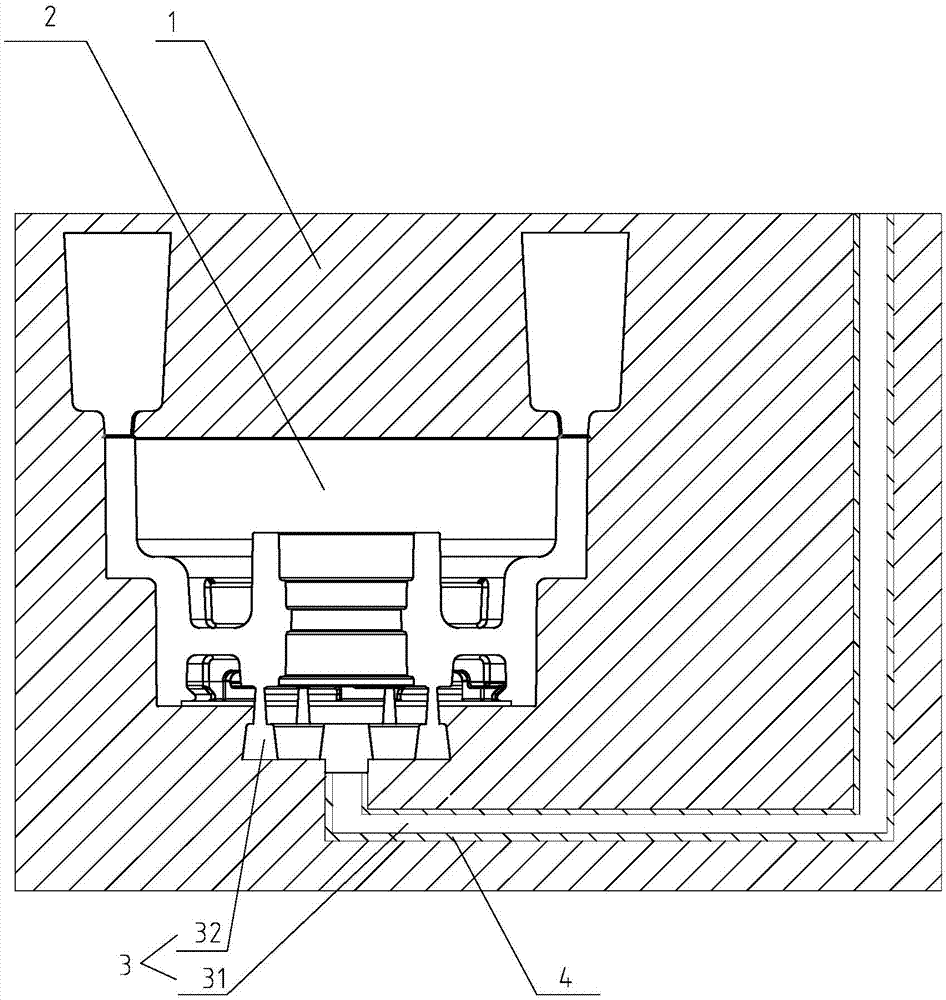

[0014] refer to figure 1 , shows an improved rotor sand mold, the sand mold 1 is provided with a cavity corresponding to the shape of the rotor casting 2, the sand mold 1 is provided with a pouring hole 3, and a pouring pipe 4 is provided on the pouring hole 3. The pouring pipe 4 plays a protective role and reduces the scour of the molten iron to the pouring hole 3 .

[0015] Preferably, the pouring tube 4 is a ceramic tube. Ceramic materials have super hardness and wear resistance, are no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com