Chassis articulation system for front and middle drive articulated buses

A technology for articulation systems and passenger cars, which is applied in the direction of connecting vehicles, vehicle components, transportation and packaging, etc., can solve the problems of poor structural technical logic safety, single structure at the joint, and high safety hazards, and achieve guaranteed strength. , save raw materials, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

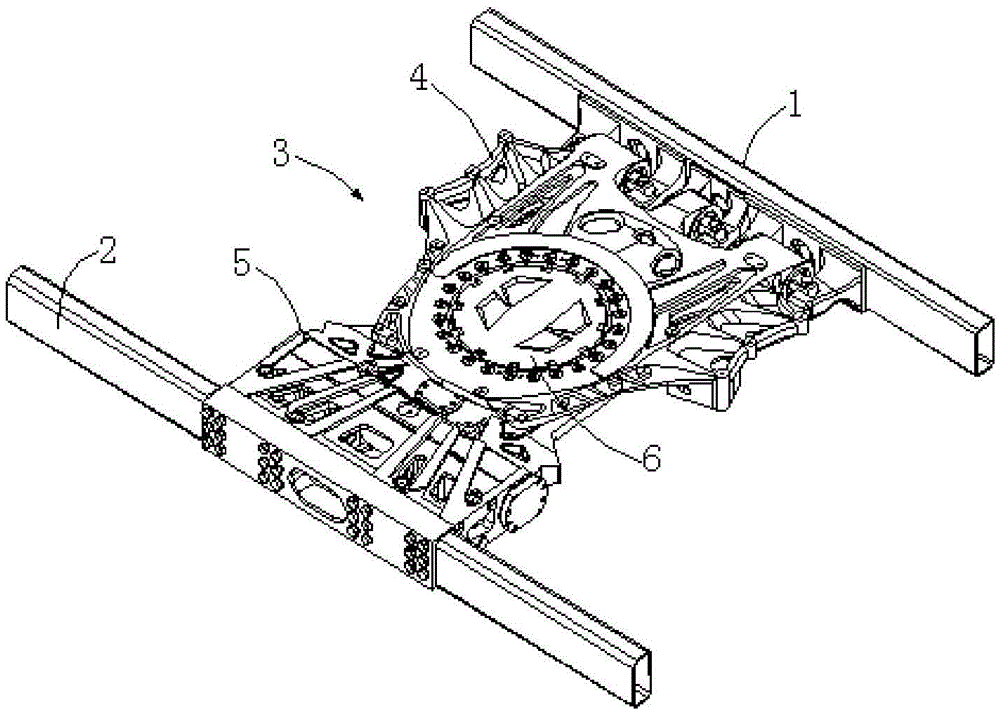

[0035] The chassis hinge system disclosed by the present invention is used to connect the front and rear compartments of an articulated passenger car, and is mainly suitable for front and middle drive articulated passenger cars. combine figure 1 and Figure 10 As shown, it is installed between the front beam assembly 1 and the rear beam assembly 2, the front beam assembly 1 is fixedly connected with the front compartment 8 of the articulated bus, and the rear beam assembly 2 is fixed with the rear compartment 9 of the articulated bus Connected, the chassis articulation system 3 realizes the articulation of the front and rear compartments of the articulated bus through the front and rear beam assemblies 1.

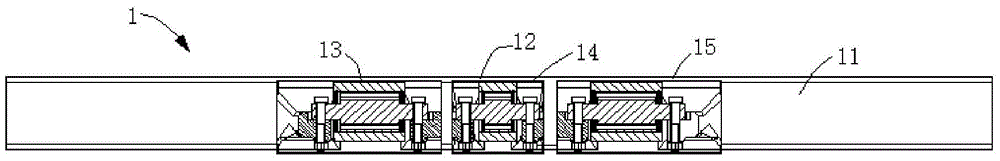

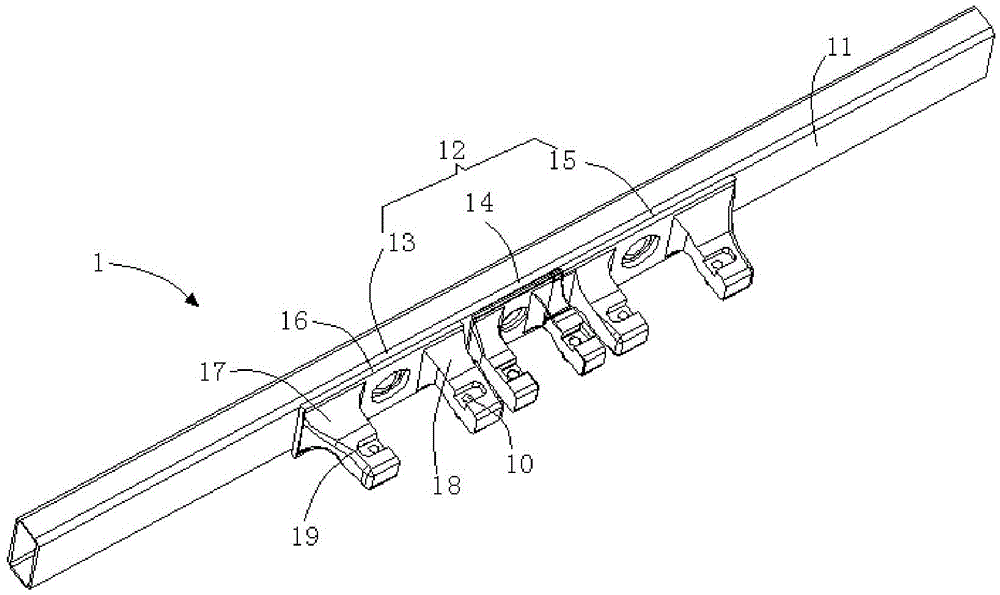

[0036] Such as figure 2 As shown, the front beam assembly 1 includes a fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com