Material sub-packaging machine

A technology of packing machine and materials, applied in packaging, solid materials, transportation and packaging, etc., can solve the problems of insufficient track width, power consumption, slow measurement and packaging, etc., achieving good buffering effect, saving energy and reducing power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

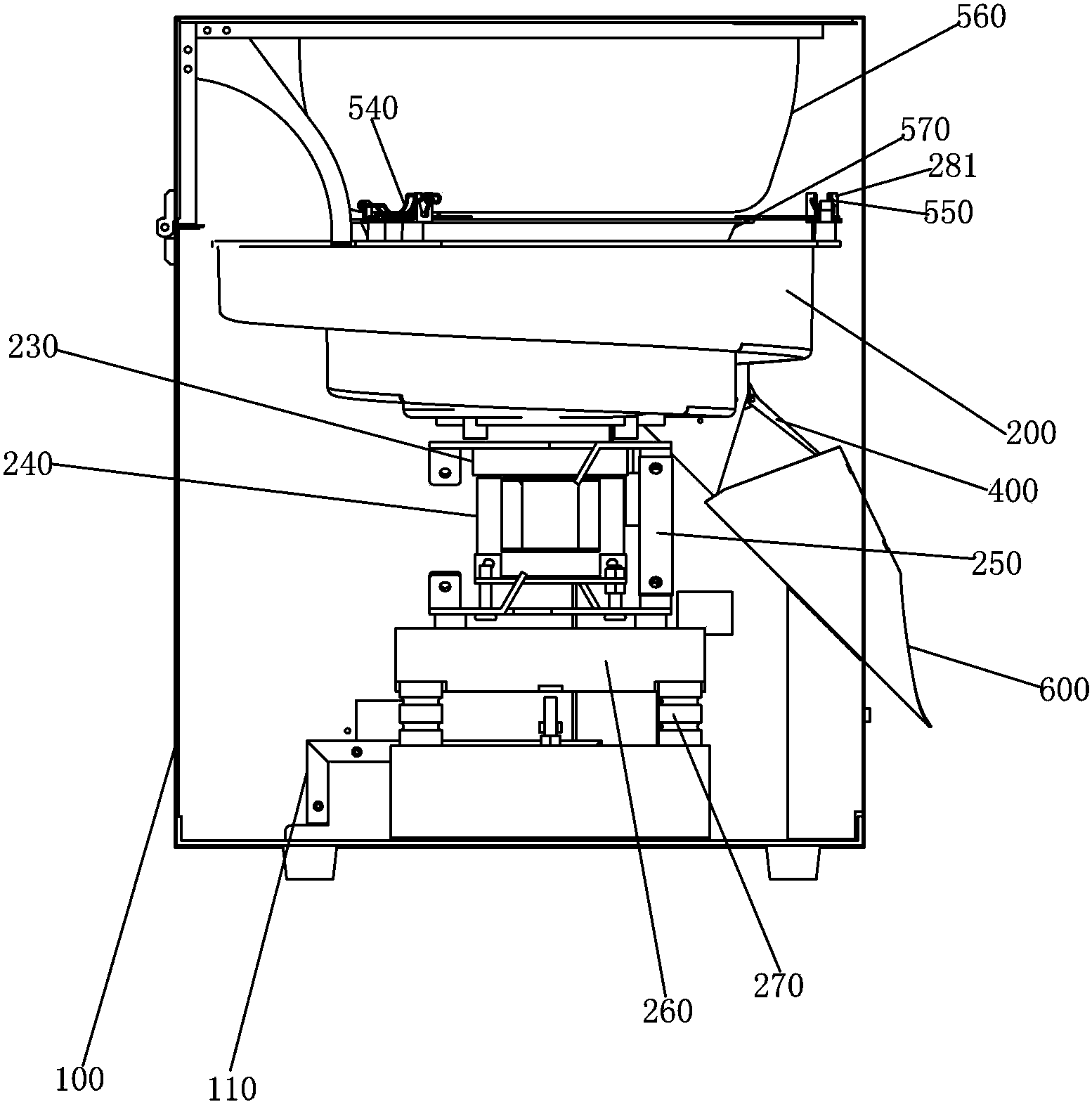

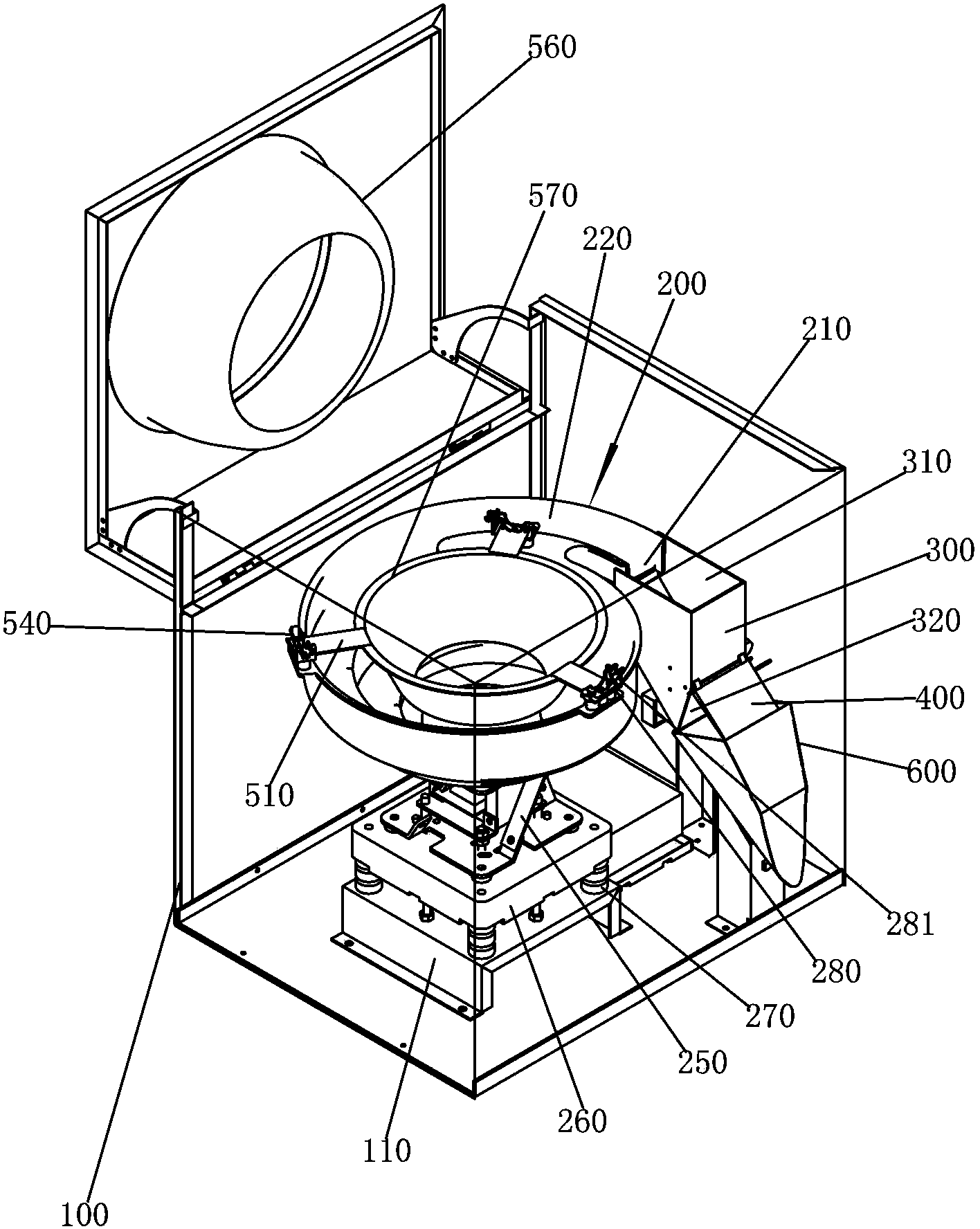

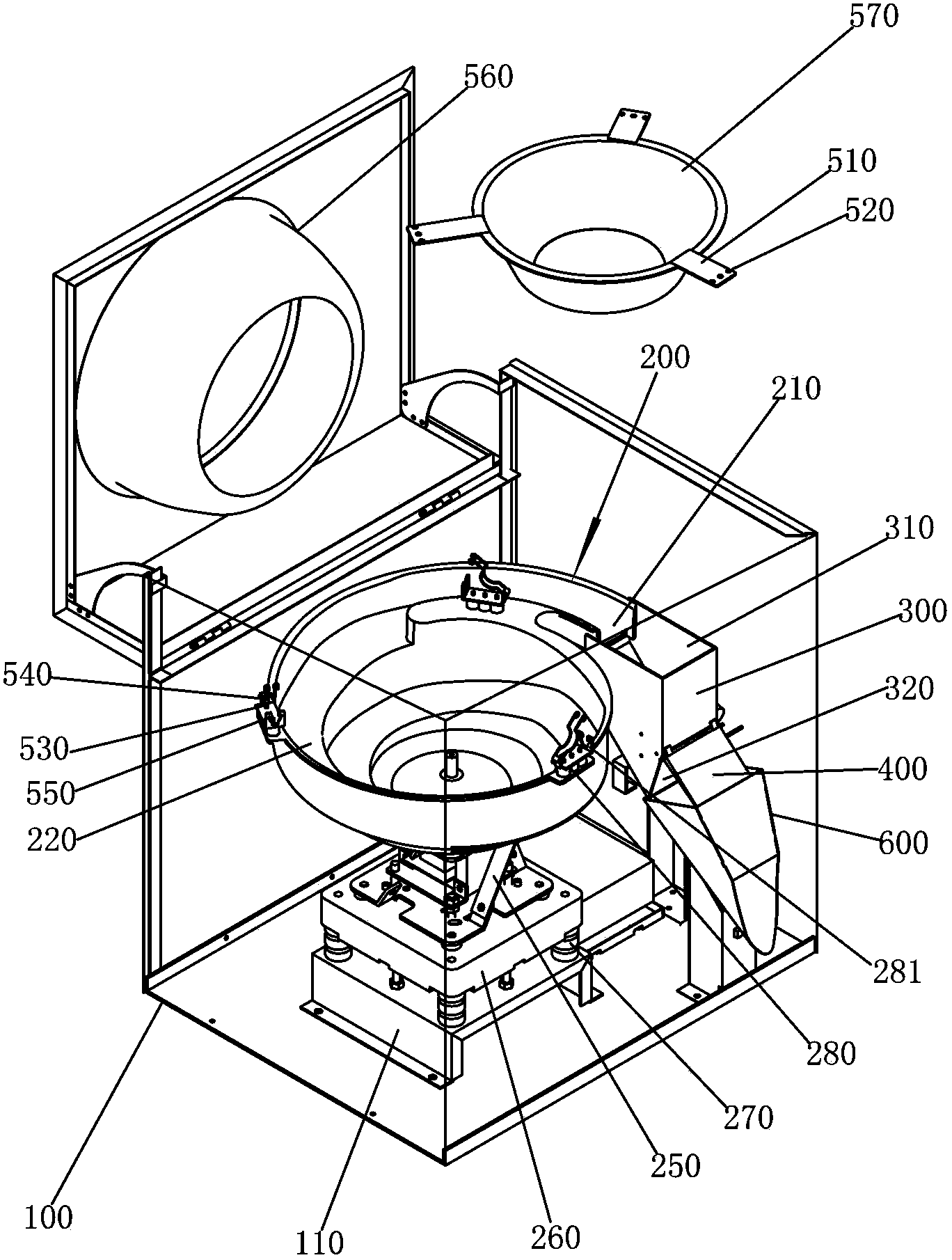

[0028] Please check Figure 1 to Figure 3 , a preferred embodiment of the material dispensing machine, the material dispensing machine, it includes a frame 100, a vibrating mechanism, a weighing mechanism, a baffle turning mechanism, a storage hopper and a buffer hopper 570.

[0029] A fixing base 110 is fixed inside the frame 100 . In this embodiment, the sidewall of the frame 100 is provided with a first opening and a second opening.

[0030] The vibrating mechanism can make the material rotate upwards. It is installed in the frame 100 and includes a vibrating drive unit and a vibrating plate 200 connected to the vibrating driving unit. The vibrating plate 200 is provided with a discharge port 210 .

[0031] In this embodiment, the vibrating plate 200 is provided with a track 220 , and the track 210 spirally rises along the inner wall of the vibrating plate 200 and extends from the bottom surface of the vibrating plate 200 to the outlet 210 . The length of the track is des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com