Preparation method of bisphenol A solid phase extractant based on dummy template covalently imprinted silica gel

A solid-phase extraction agent and pseudo-template technology, applied in the field of preparation of bisphenol A solid-phase extraction agent, can solve the problem of template leakage of non-specific recognition sites and the like, and achieve the effect of high selective recognition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Under the protection of nitrogen, add hexafluorobisphenol A and 3-propylisocyanotriethoxysilane, hexafluorobisphenol A and 3-propylisocyanotriethoxy to anhydrous tetrahydrofuran solvent The molar ratio of base silane is 0.5:2, and then reacted at 50°C for 50h, and after the solvent was evaporated to dryness by rotary evaporation, it was separated and purified by silica gel chromatography to obtain a viscous oil;

[0030] (2) Mix and stir the porogen P123, NaCl, water and HCl until completely dissolved, as a template stock solution;

[0031] (3) Take the product of step (1) and the template stock solution of step (2) and tetraethyl orthosilicate for 20 h at room temperature, the product of step (1) and the template stock solution of step (2) and orthosilicate The weight ratio of ethyl silicate is 0.1:30:1, and then dried at 70°C for 30 hours to obtain mesoporous organic silica gel, and then use methanol as solvent to remove P123 in mesoporous silica gel through Soxhl...

Embodiment 2

[0035] (1) Under the protection of nitrogen, add hexafluorobisphenol A and 3-propylisocyanotriethoxysilane, hexafluorobisphenol A and 3-propylisocyanotriethoxy to anhydrous tetrahydrofuran solvent The molar ratio of base silane is 2:2, and then reacted at 80°C for 30h, and after the solvent was evaporated to dryness by rotary evaporation, it was separated and purified by silica gel chromatography to obtain a viscous oil;

[0036] (2) Mix and stir the porogen P123, NaCl, water and HCl until completely dissolved, as a template stock solution;

[0037] (3) Take the product of step (1) and the template stock solution of step (2) and tetraethyl orthosilicate at room temperature for 30 hours of mixed reaction condensation, the product of step (1) and the template stock solution of step (2) and orthosilicate The weight ratio of ethyl silicate is 1:60:3, and then dried at 90°C for 20 hours to obtain mesoporous organic silica gel, and then use methanol as solvent to remove P123 in meso...

Embodiment 3

[0041] 3.1 Preparation of new intermediates of BPAF-Si

[0042] Under nitrogen protection, BPAF (4.0 g, 12 mmol) and ICPTES (6.0 mL, 24 mmol) were reacted at 65° C. for 40 h in anhydrous tetrahydrofuran (THF). After the solvent was evaporated by rotary evaporation, it was separated and purified by silica gel chromatography to obtain a viscous oil, which was confirmed to be the target product BPAF-Si by infrared spectroscopy. The reaction yield was 80%. The reaction scheme is as follows:

[0043]

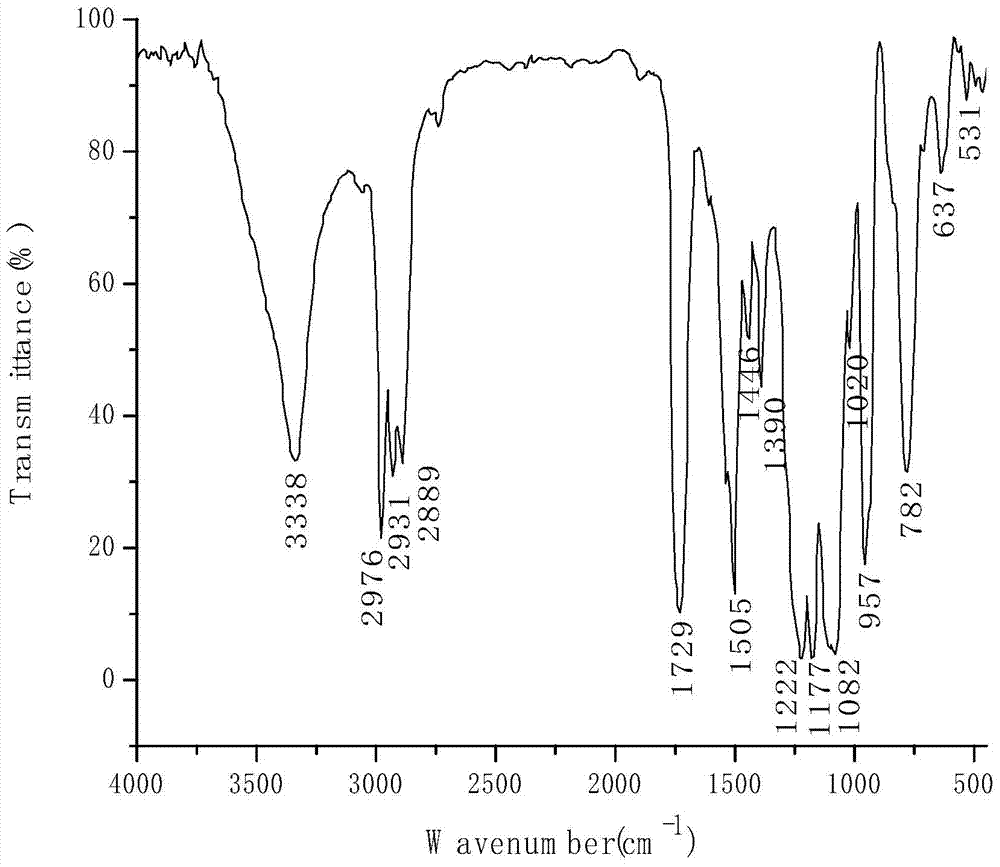

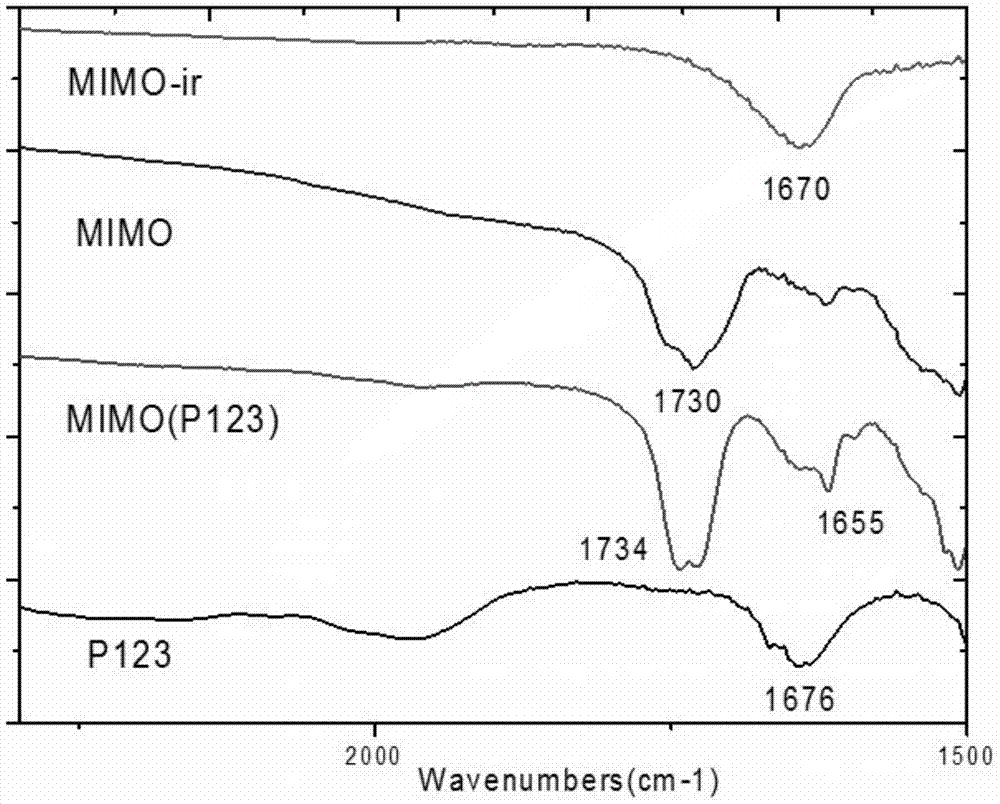

[0044] figure 1 is the infrared spectrum of the intermediate BPAF-Si, from figure 1 It can be seen that in the infrared spectrum of ICPTES at 2270cm -1 There is a strong -NCO absorption peak at figure 1 There is no obvious absorption peak at the corresponding position in , indicating that there is no -NCO group in the product, that is, the ICPTES reaction is complete; in addition figure 1 at 1720cm -1 There is a strong absorption peak at , which is caused by the stretching vi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap