Optical fiber sensor and preparation method thereof

A fiber optic sensor, sensor body technology, applied in the direction of instruments, optics, light guides, etc., can solve the problems of easy breakage in the waist area, and the sensor cannot be used in the detection environment, so as to ensure gas-sensing characteristics, not easy to damage, and tightly combined. solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

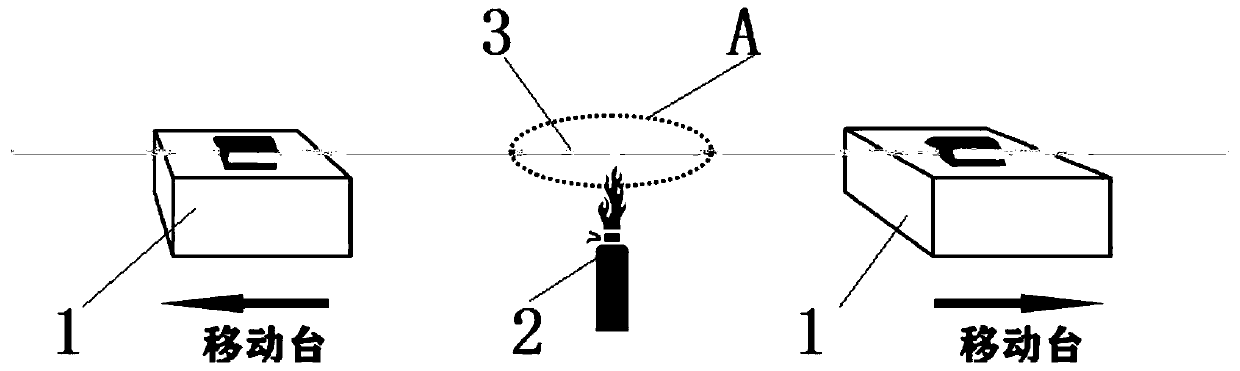

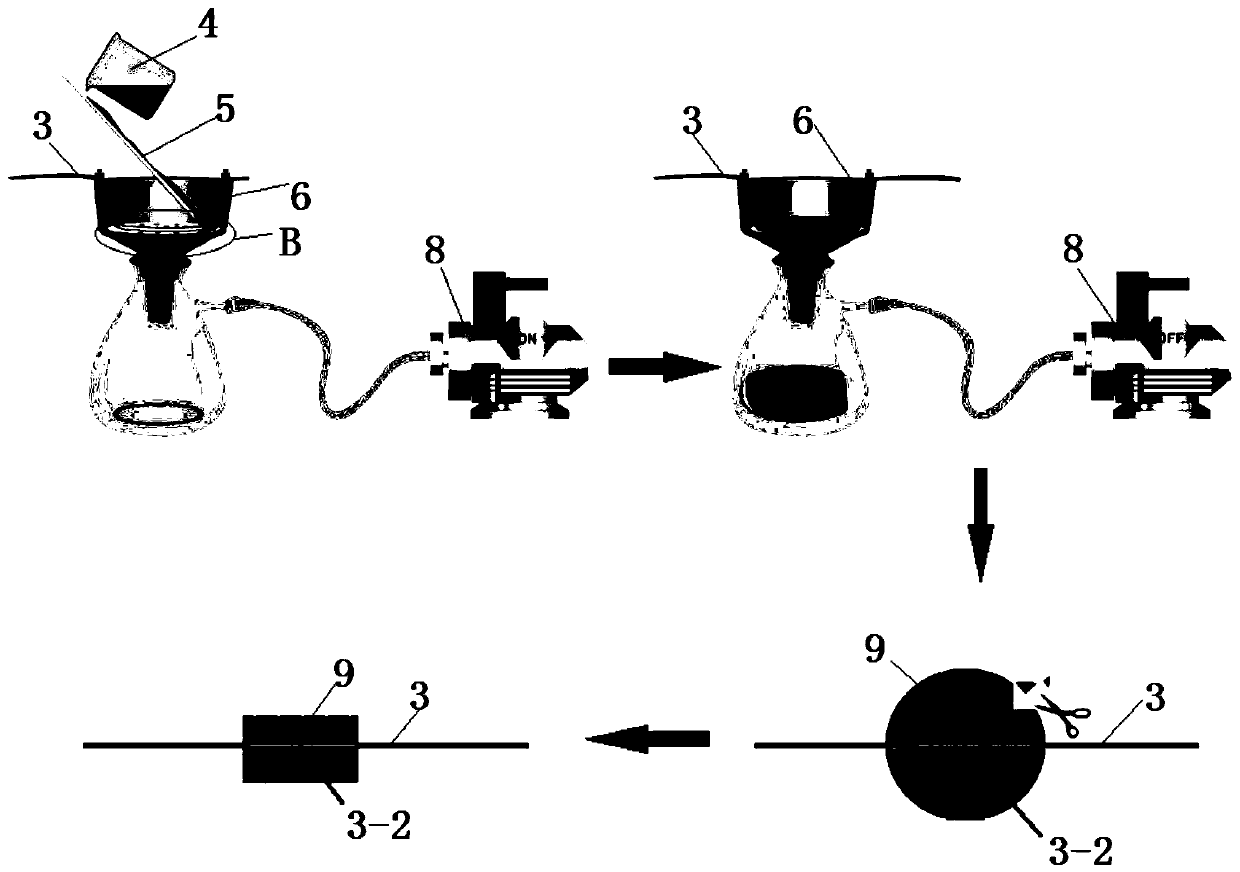

[0050] A kind of preparation method of optical fiber sensor of the present invention comprises following process:

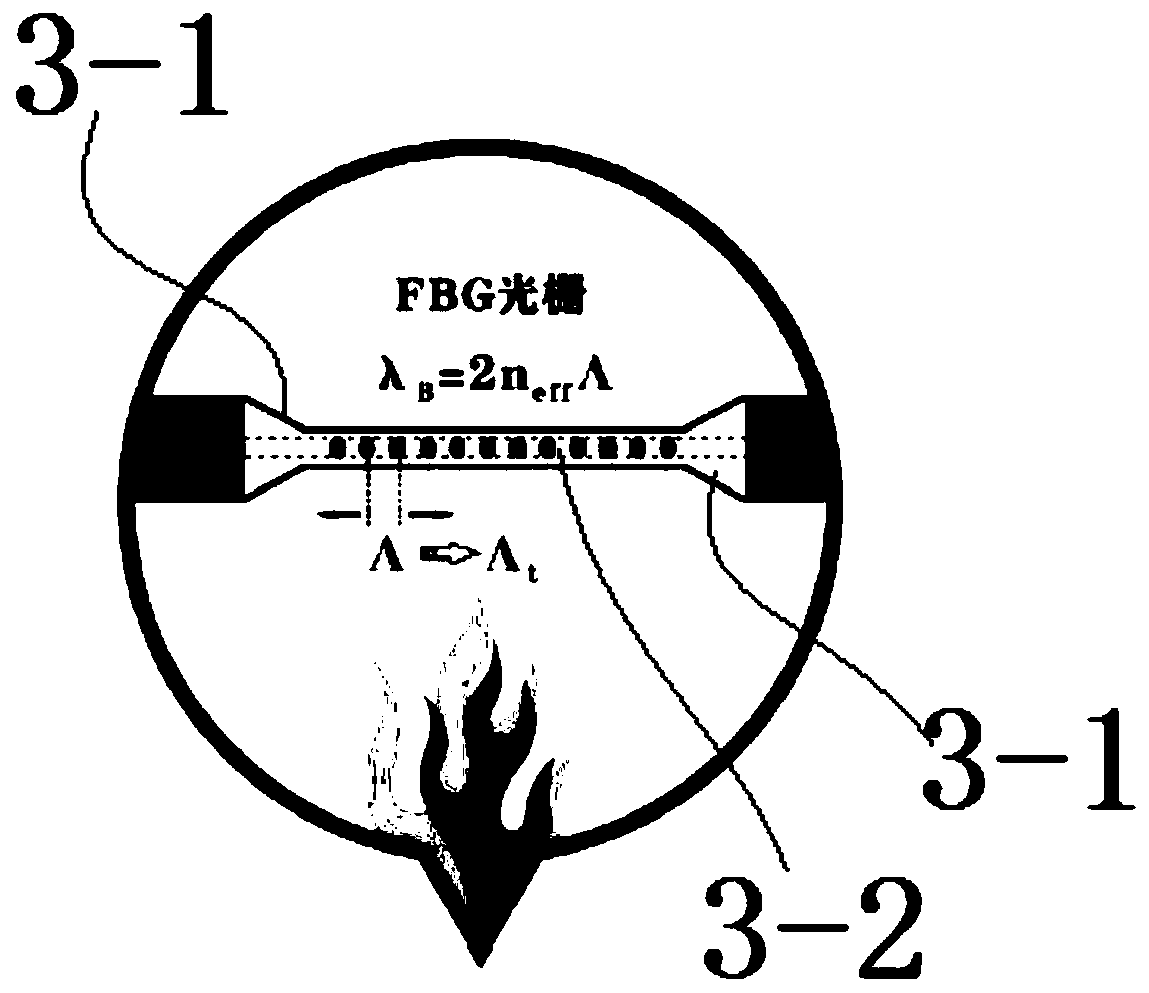

[0051] The Bragg grating is processed by the fusion tapering method to form a tapered transition zone and a waist zone with a diameter of micro-nano scale;

[0052] The graphene is coated on the waist region by using the graphene dispersion liquid and vacuum filtration, and a graphene film 10 is formed on the waist region, and the optical fiber sensor is obtained after separating the filter paper.

[0053] In the present invention, the graphene material is coated on the waist region of the single-cone interference micro-nano optical fiber sensor by a vacuum filtration preparation process, and the structural characteristics and strong adsorption capacity of graphene are used to improve the sensitivity and response characteristics of the sensor and further improve the optical fiber sensor. The sensor selectively recognizes and detects harmful gas molecules, and can...

Embodiment

[0079] What this embodiment adopts is nano-silver doped graphene to prepare optical fiber sensor, specific steps are as follows:

[0080] 1. Preparation of Ag nanoparticles doped graphene composites

[0081] specific methods:

[0082] ①Put the purchased GO powder into deionized water and disperse it ultrasonically for 1 hour to prepare a 0.5 mg / mL GO uniform dispersion. In the graphene oxide dispersion, the graphene oxide content is 0.5 mg / mL;

[0083] ②Add 35mL of dimethylacetamide aqueous solution to 35mL of the graphene oxide dispersion prepared in step ①, and magnetically stir for 1.5h; Dimethylacetamide (DMAc) and H 2 The volume ratio of O is 1:1;

[0084] ③ 3g silver nitrate (AgNO 3 ) into water to form a silver nitrate solution with a mass percentage of solute of 5%, AgNO 3 The mass ratio of content to GO in GO aqueous dispersion is 10:1, at this time, the AgNO 3 The aqueous solution was added dropwise to the above solution, and stirred for 10 min to ensure complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com