Silk drafting/drying device

A drying and silk technology, applied in rayon cleaning/drying, rayon physiotherapy, textiles and papermaking, etc., can solve the problems of temperature uniformity and stable drafting of tow, and reduce equipment cost and occupation. land area, reducing recycling load and energy consumption, and improving the effect of vapor concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

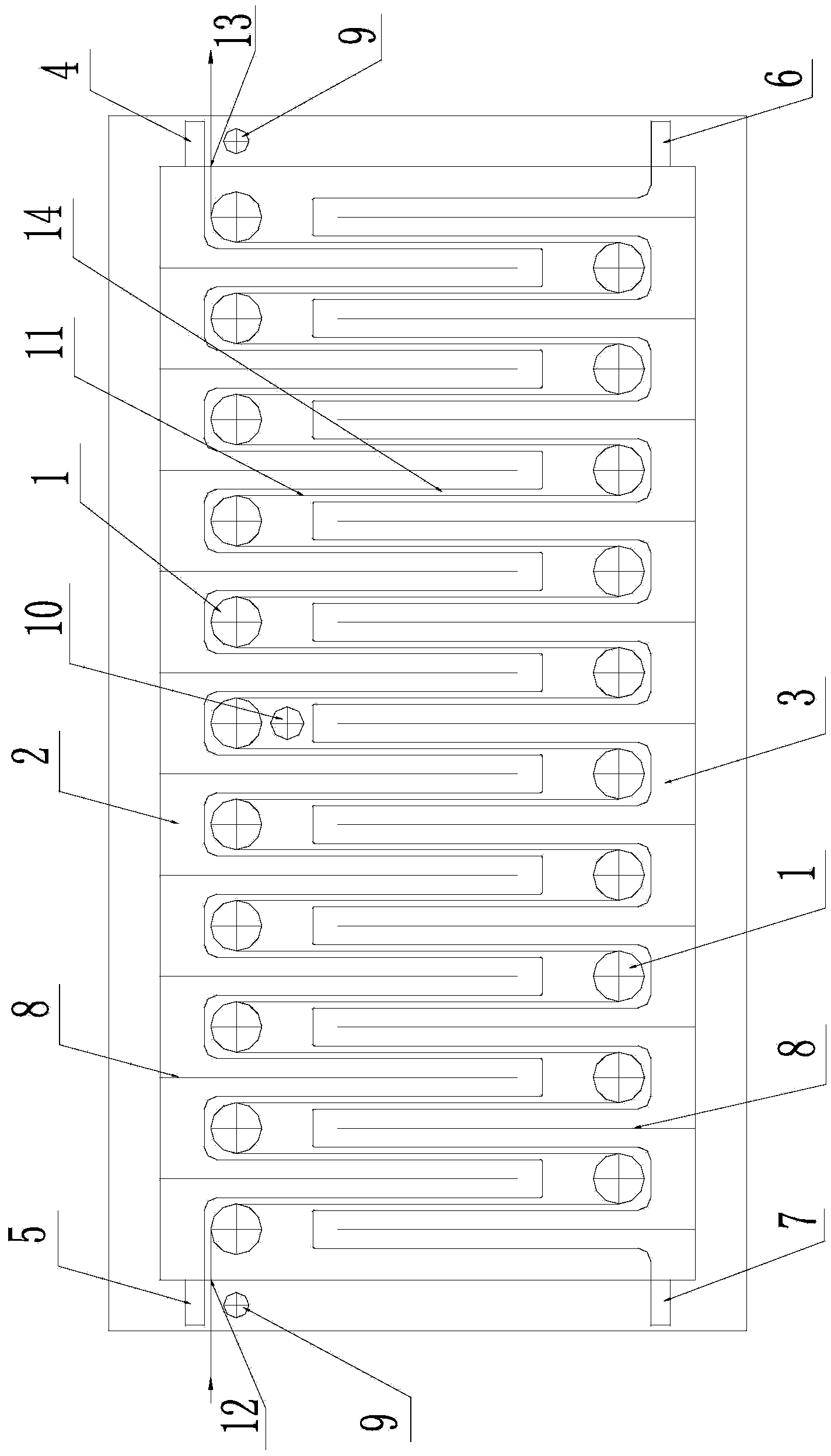

[0041] Such as figure 1 As shown, in this example, a total of 21 independently driven drafting rollers 1 are designed, which are arranged in two parallel and staggered rows, including 11 in the upper row and 10 in the lower row, with a roller length of 280mm and a roller diameter of 200mm. The distance between the centers of the two drafting rollers is 400mm, the difference between the lower row of drafting rollers and the upper row of drafting rollers is 200mm, the distance between the center heights of the upper and lower rows of drafting rollers is 1500mm, and the wire inlet is set at the first drafting roller of the upper row , the tow exit is set at the last drafting roller in the upper row.

[0042] The heating plate is divided into upper and lower parts, both of which are rectangular toothed. The teeth of the upper heating plate are downward, and the teeth of the lower heating plate are upward, interlaced with each other. Among them, the upper heating plate has 10 rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com