Non-reflux adjustable square cone manifold

A main pipe and flow blocking technology, which is applied in the field of backflow-free and finely adjustable square cone main pipe, can solve the problems of increasing the amount of slurry supplied, increasing the power consumption of the sizing pump, manufacturing and installation errors of the flow blocking elements, etc., and achieves a large adjustment range, Effective and precise adjustment effect, reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

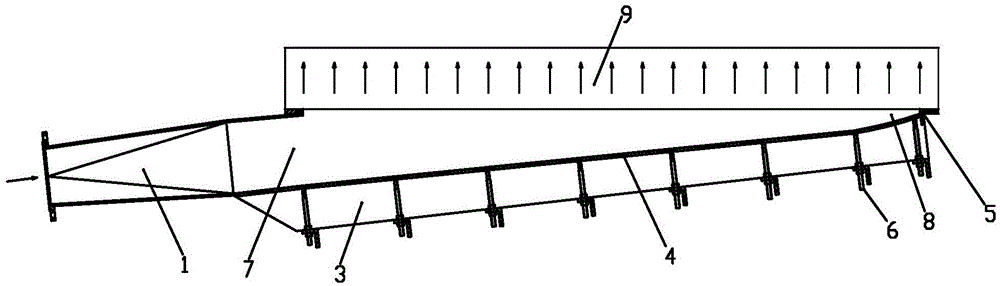

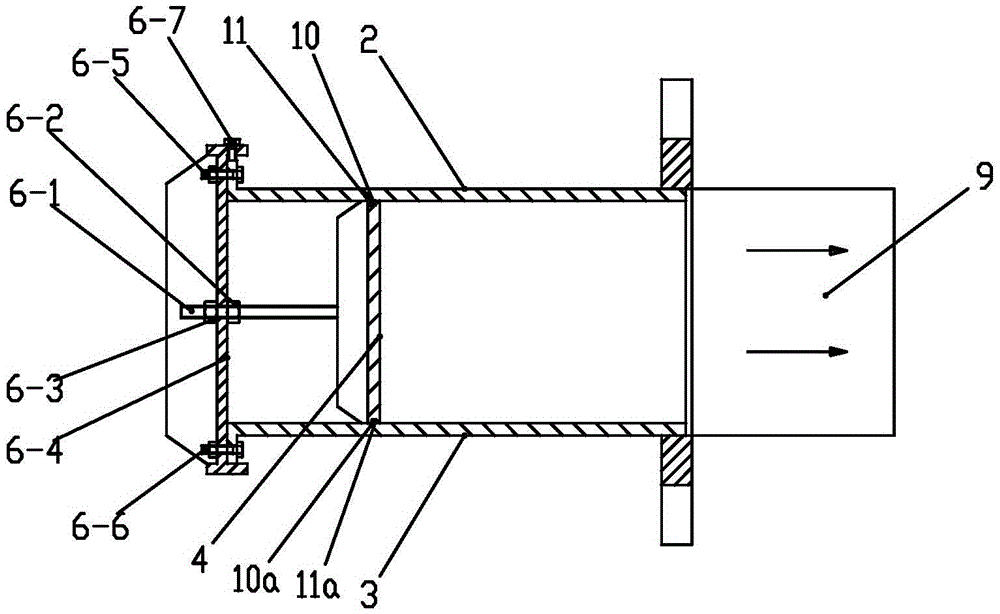

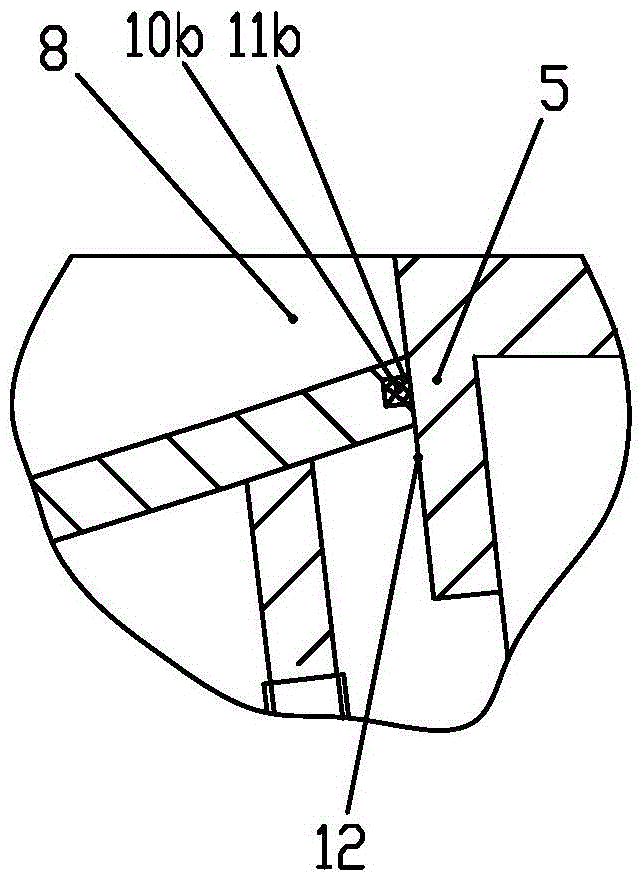

[0027] Such as figure 1 As mentioned above, the present invention provides a finely adjustable square cone manifold without backflow, including a top plate 2 and a bottom plate 3, a movable vertical plate 4 and a slurry distribution blocking element 9 are arranged between the top plate 2 and the bottom plate 3, the top plate 2, the bottom plate 3. The vertical plate 4 and the slurry distribution blocking element 9 form a square conical main pipe cavity, the large end 7 of the square conical main pipe cavity is equipped with a transition pipe 1, and the small end of the square conical main pipe cavity An end plate 5 is installed at the end 8, an inlet is provided on the transition pipe 1, and a small hole is provided on the pulp distributing flow blocking element 9 to allow the pulp to flow out evenly.

[0028] Such as figure 2 As shown, the vertical plate 4 among ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com