Key groove sealing structure of drum gear coupling

A technology of sealing structure and coupling, applied in the direction of coupling, elastic coupling, engine sealing, etc., can solve the corrosion of coupling and motor/gearbox keyway, low sealing safety margin, high risk, etc. The problem is to avoid water and other impurities from entering the gap, the sealing performance is good, and the sealing structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

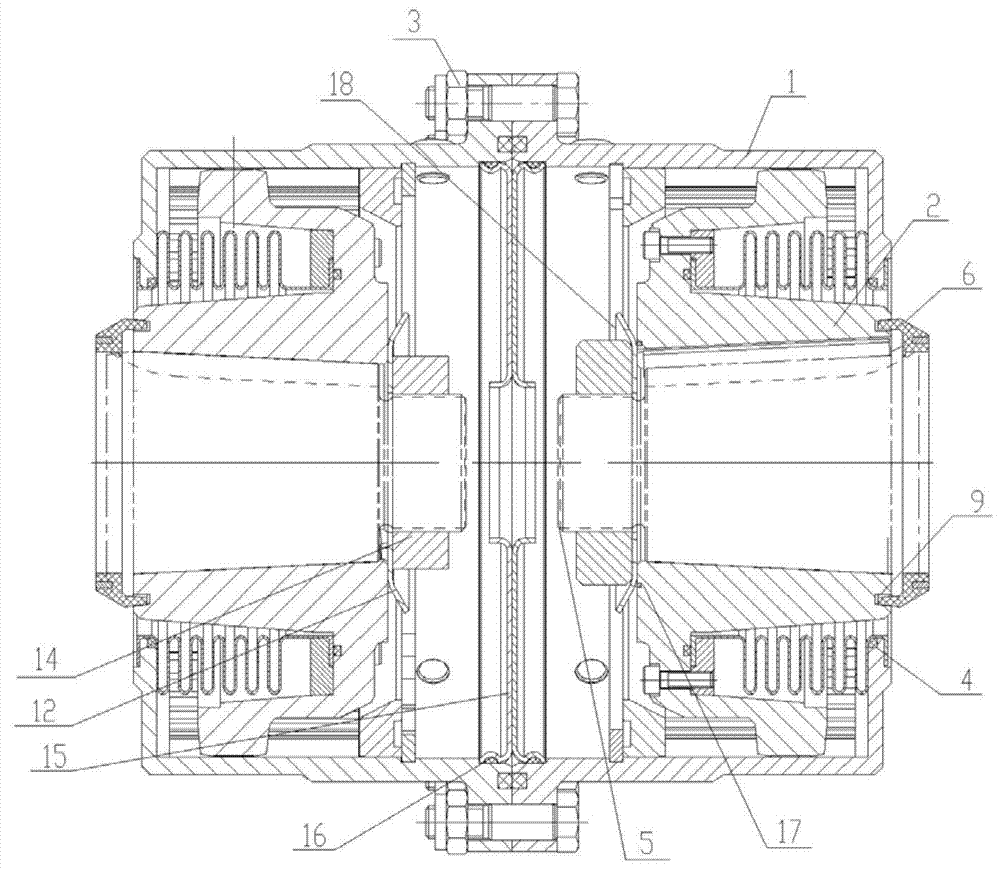

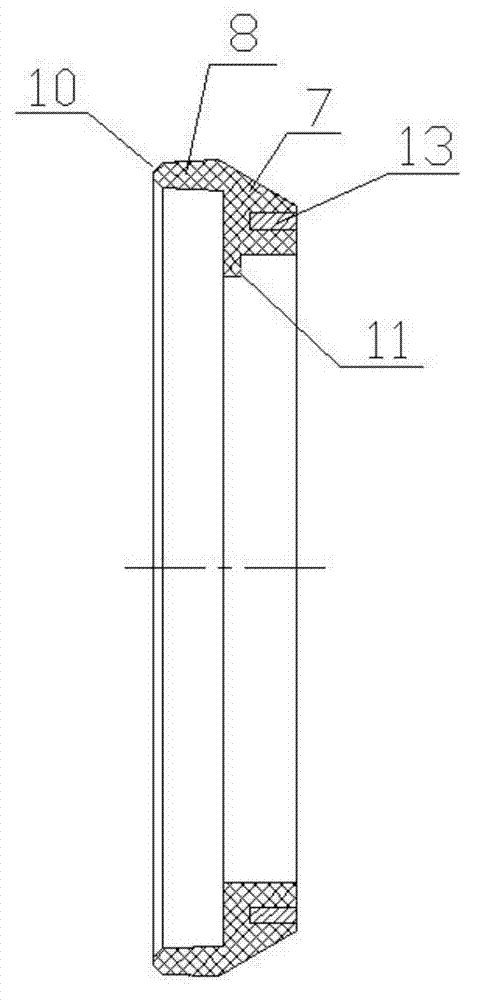

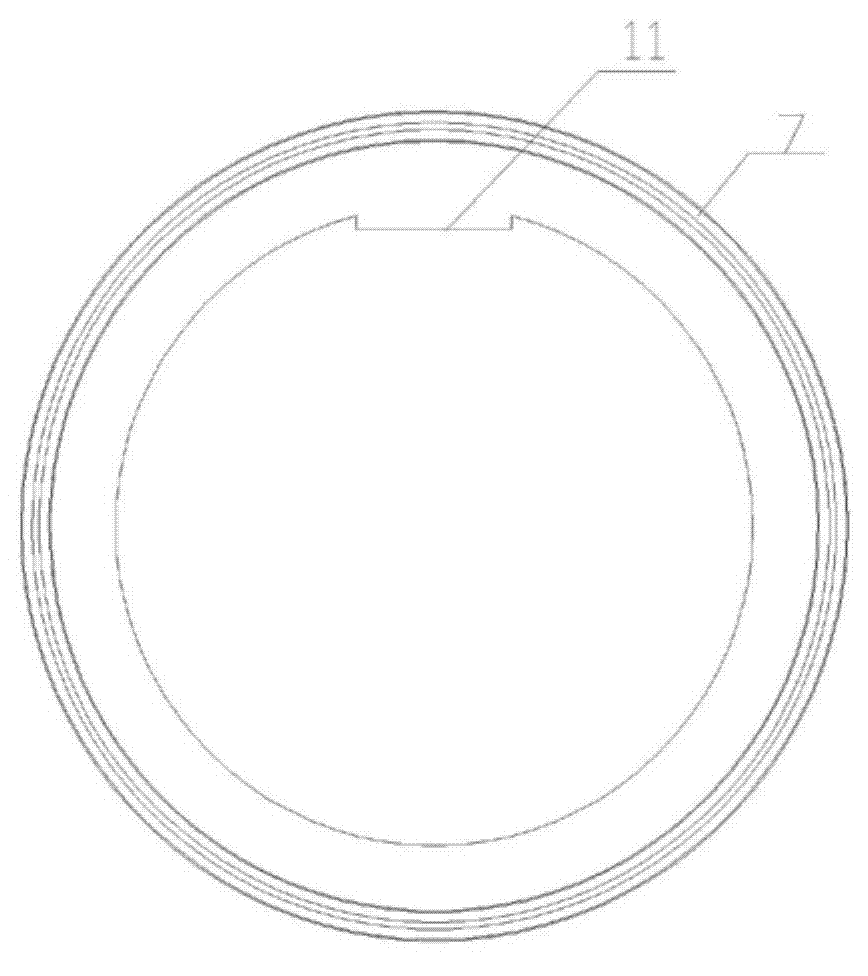

[0023] figure 1 As shown, the present invention provides a drum-shaped gear coupling keyway sealing structure, and the coupling is assembled from two half-couplings on the motor side and the gearbox side. Each half-coupling includes a housing 1 with internal teeth and a sleeve 2 with external teeth. The internal teeth on the housing 1 and the external teeth on the sleeve 2 mesh with each other to form relative movement. The front end of the housing 1 is bent toward the center. Form an integral protective front end cover structure, a sealing ring 4 is provided between the shell 1 and the sleeve 2, and the shells 1 of the two half-couplings are connected together with bolts 3 to form a complete coupling. The shaft 5 connected by the shaft coupling is connected with the sleeve 2 through a key.

[0024] The inner wall of the sleeve 2 and the shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com