One-way loop gravity assisted heat pipe and manufacturing method thereof

A technology of gravity heat pipe and loop heat pipe, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of low heat transfer efficiency, slow start, uncertain flow direction, etc., to achieve low cost, high efficiency utilization, structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

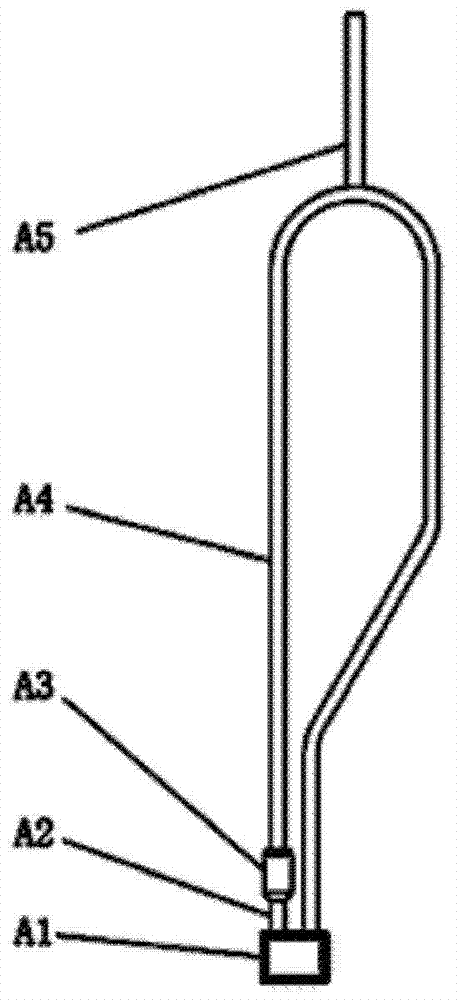

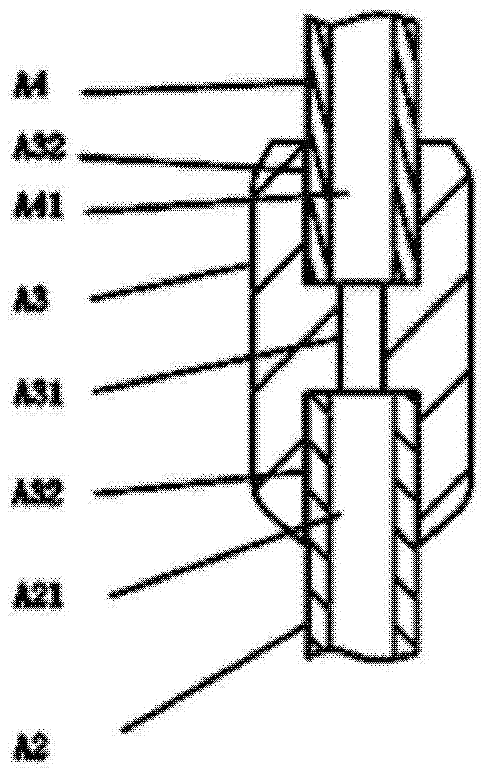

[0040] Such as figure 1 As shown, the basic structure of a one-way loop gravity heat pipe shell according to the present invention includes: a liquid bag A1, a short connecting pipe A2, a shrinking and reducing joint A3, a long connecting pipe A4 and a liquid filling port A5. Among them, the liquid bag A1, the short connecting pipe A2, the shrinking and reducing joint A3, and the long connecting pipe A4 all use the same metal material, and are welded in sequence to form a loop; wherein, the internal structure of the shrinking and reducing joint A3 is as follows: figure 2 As shown, the upper end connecting channel A32 of the internal shrinking pipe A31 is connected to the long connecting pipe A4, and the lower end connecting channel A32 of the shrinking pipe A31 is connected to the short connecting pipe A2; the diameter of the shrinking pipe A31 is smaller than the internal pipe A41 of the long connecting pipe. and the diameter of the inner pipe A21 of the short connecting pip...

Embodiment 2

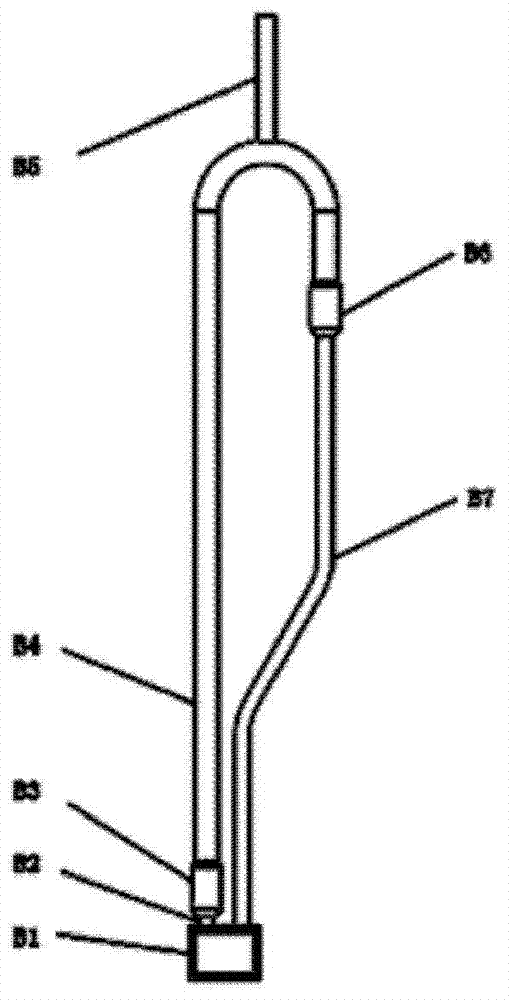

[0043] The one-way loop gravity heat pipe of the present invention can also be made of metal pipes with different diameters. Such as image 3 As shown, in some occasions, due to the limitation of space and heating end, the short connecting pipe B2 connected with the liquid bag and the long connecting thin pipe B7 must use the same specification and thinner diameter metal pipes. In order to enhance heat dissipation and reduce the flow resistance of the working fluid in the heat dissipation pipeline, it is often necessary to introduce a thicker long connecting thick pipe B4 into the heat pipe loop that plays a role in heat dissipation to form a flared variable diameter joint B6 and a narrowed joint B6. The heat dissipation loop of the thick and thin tubes of the reducing joint B3. Thus, the shell of a one-way loop gravity heat pipe according to the present invention can be composed of a liquid bag B1, a short connecting pipe B2, a shrinking and reducing joint B3, a long connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com