Measurement method for rotary kiln cylinder coaxiality

A technology of coaxiality measurement and rotary kiln, which is applied in the field of rotary kiln, can solve the problems of large influence, large influence of weather, increase of measurement error, etc., and achieve the effect of simple operation, high measurement accuracy and accurate measurement value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

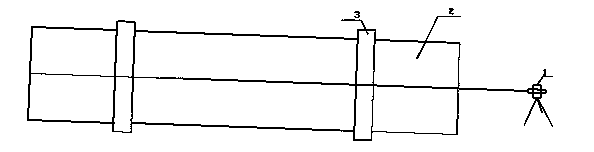

[0017] Such as figure 1 and figure 2 Shown, the implementation steps of the present invention:

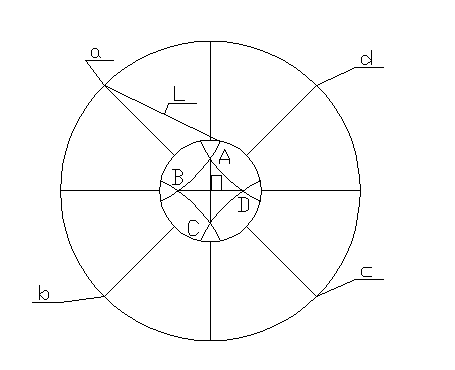

[0018] Step 1: Before hoisting the rotary kiln shell, use a drawing rule to draw four arcs at the four points at the two ends of each section of the shell. The intersection point is the center of the cylinder, and the cross line formed by connecting the four points is the center of the cylinder. The four arcs intersect at points A, B, C, and D; connecting AC and BD must intersect at point O in the center of the circle, and AC and BD are the cross lines in the center of the cylinder. , and then carry out cylinder hoisting work;

[0019] Step 2: After the hoisting of the entire cylinder is completed, set the measured points at the center of the Pozider braces at both ends of each section of the cylinder, and set a round hole (the center of the cylinder) at each measured point. The sizes of the round holes are Φ45, Φ40, Φ35, Φ30, Φ25..., and the largest round hole is set near the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com