Multiple pose measuring machine tail end coordinate identification method based on actual material reference

A pose measurement and coordinate recognition technology, applied to measuring devices, instruments, etc., can solve the problems of high cost and complicated use, and achieve the effect of low cost, simple structure and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

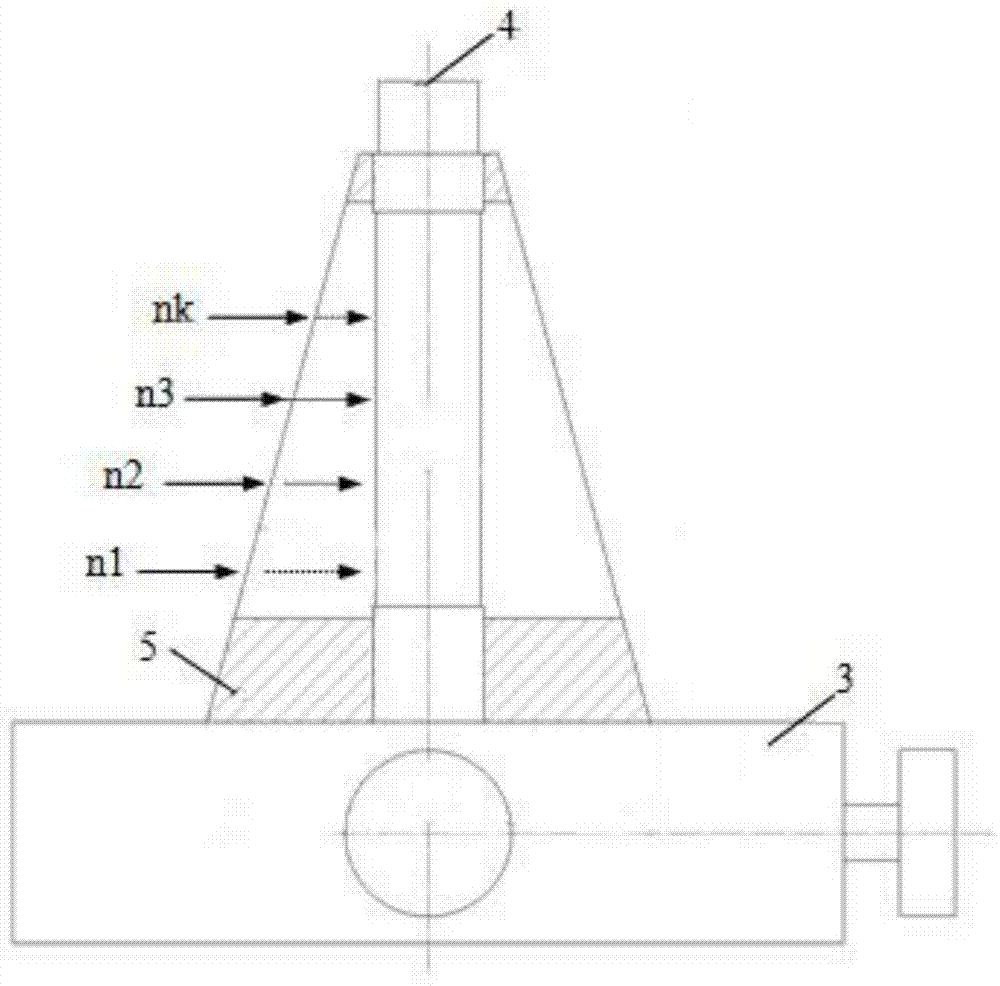

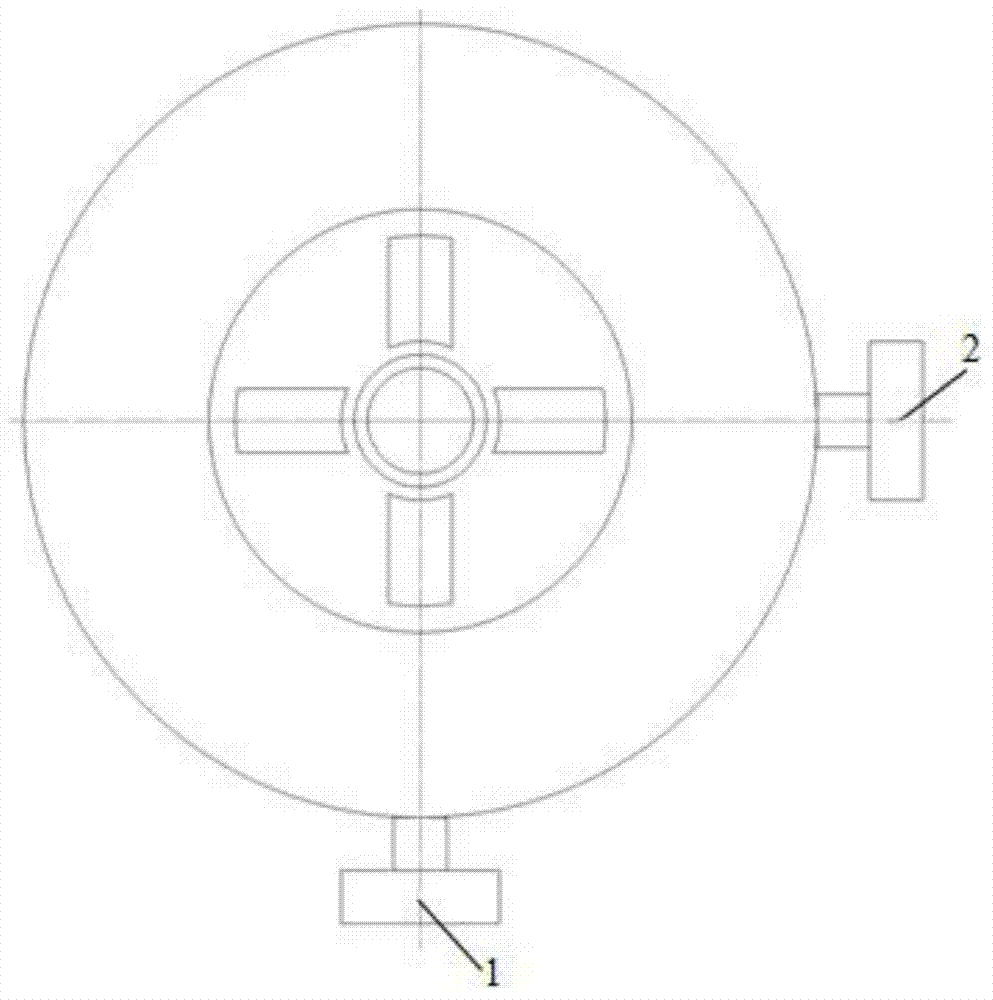

[0030] see figure 1 and figure 2 , the present invention is based on the coordinate recognition method of the end of the multi-pose and attitude measuring machine based on the physical reference, and the specific steps are as follows:

[0031] Step 1, firstly fix the physical benchmark on the state of the multi-position and attitude measuring machine;

[0032] Step 2, then adjust the physical datum and the turntable to the concentric position; the specific operation process is: use the X-direction centering knob 1 and the Y-direction centering knob 2 to set the center of the physical datum standard cylindrical surface 4 and standard conical surface 5 and the turntable The center of rotation of the machine is adjusted to be concentric. At this time, the small eccentricity is Δx=0, Δy=0, Δx is the eccentricity in the x direction; Δy is the e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap