A drop test device

A drop test and pedestal technology, which is used in measuring devices, impact testing, and testing of machine/structural components, etc., can solve problems such as large impact, difficult data collection, and poor consistency of test results, and achieve fast and easy repeated testing. Safe operation, easy adjustment and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

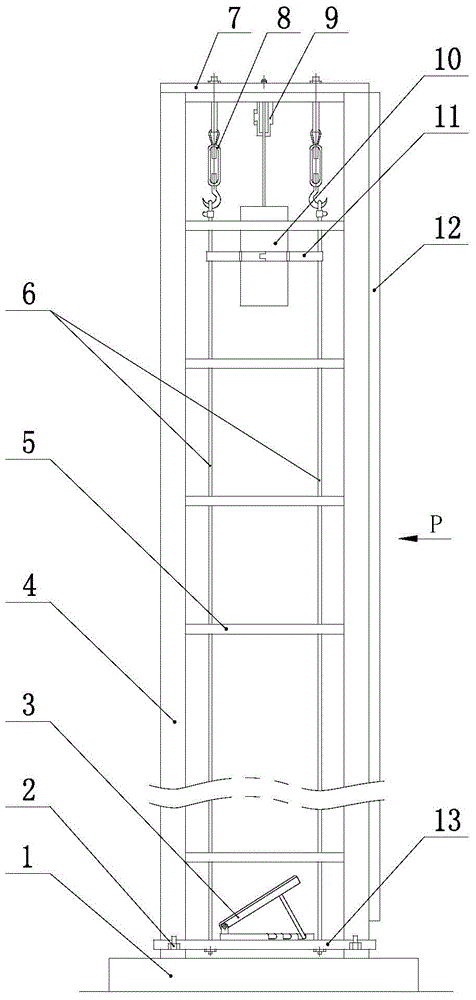

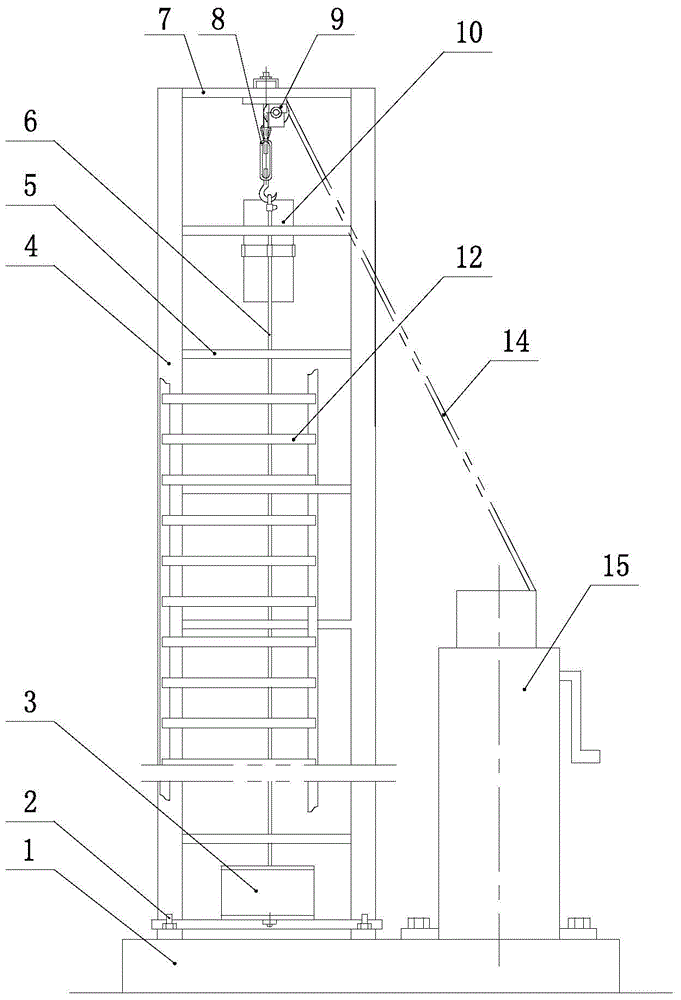

[0027] see figure 1 , figure 2 , a drop test device, which includes a base 1, a fastening bolt 2, a touch plate mechanism 3, a bracket 4, a reinforced beam 5, a guide rail 6, a top beam 7, a hook 8, a pulley 9, a clamp 10, a limit plate 11. Escalator 12, bottom beam 13, nylon rope 14, winch 15.

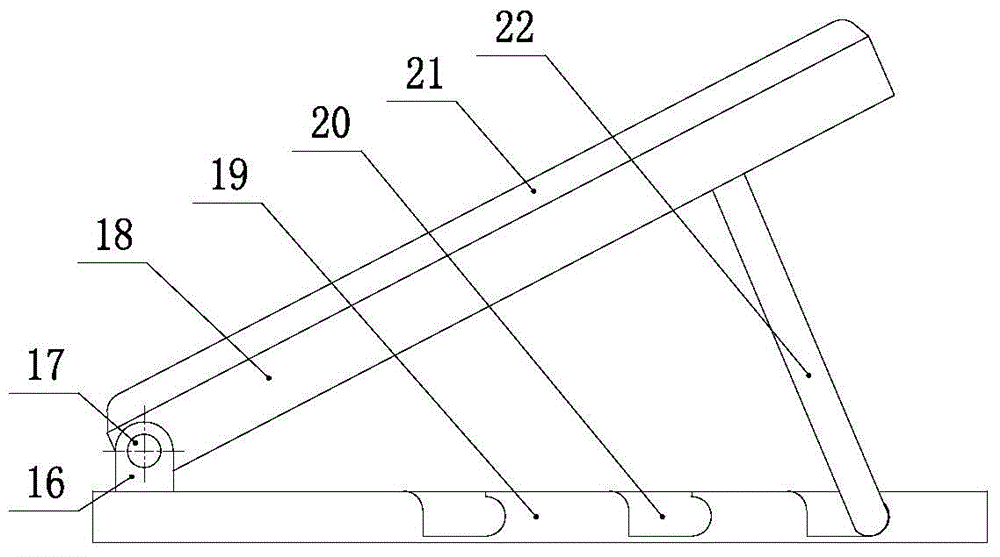

[0028] see image 3 , the touch plate mechanism 3 includes pin seat 16, shaft pin 17, touch plate seat 18, base 19, groove 20, contact plate 21, support rod 22, pin seat 16 is installed on the edge of the upper end surface of base 19, and shaft pin 17 inserts Installed in the pin hole of the pin seat 16, the contact plate seat 18 is hinged to the base 19, the contact plate 21 is firmly fixed on the upper end surface of the touch plate seat 18 by strong glue, the base 19 is provided with a plurality of grooves 20, and the support rod One end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com