PVC bottom-permeable hollow self-drainage floor mat production line

A self-draining, production line technology, applied in metal processing and other directions, can solve problems such as uneven cutting openings, large product deformation, and long cutting knives, and achieve the effect of small material consumption, small deformation of floor mats, and smooth cutting openings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and embodiments.

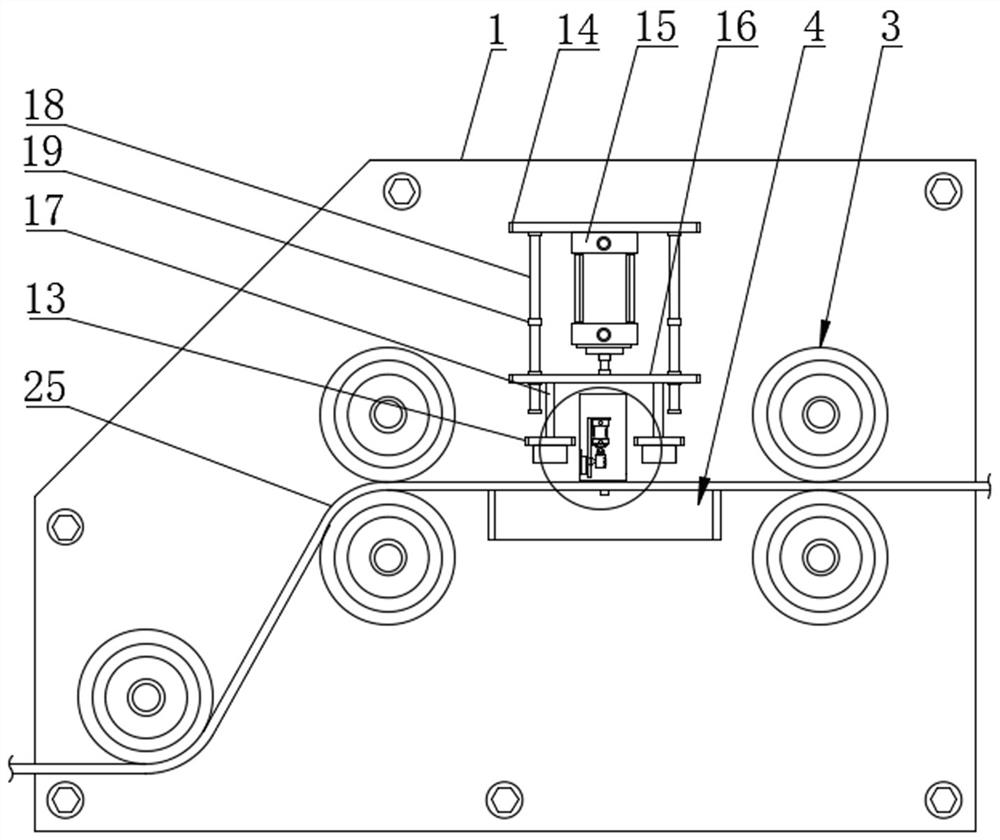

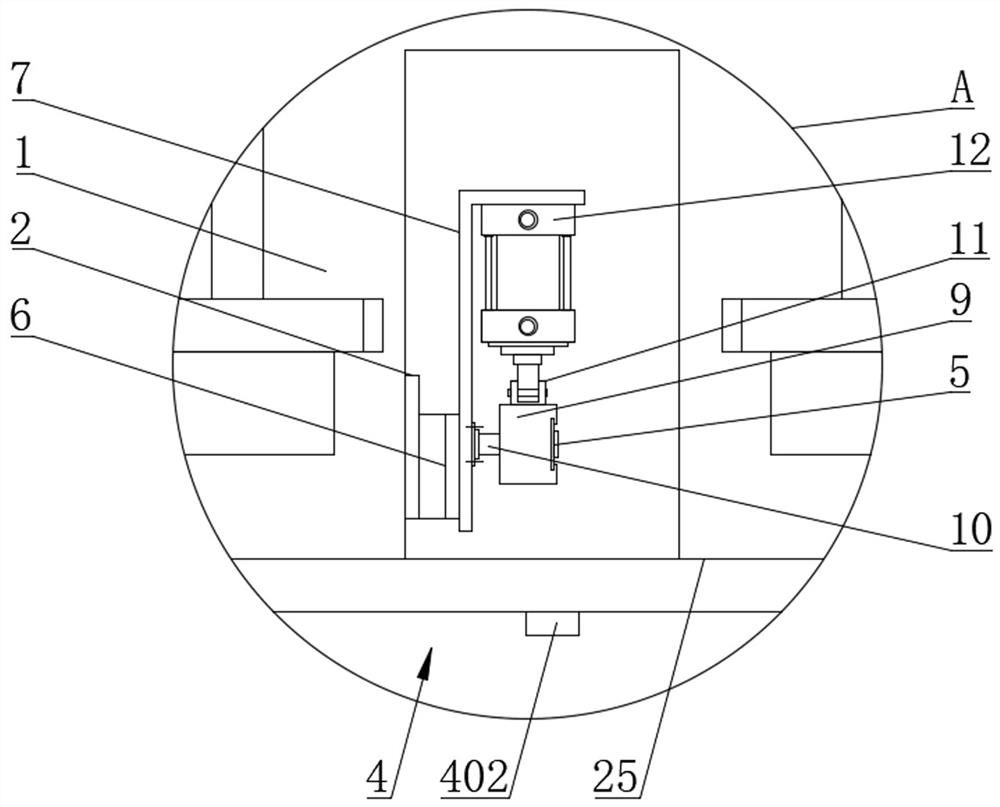

[0033] see Figure 1 to Figure 6 , The present invention includes a floor mat cutting machine, and the floor mat cutting machine includes a support panel 1 placed inside it, a guide roller set 3, a cutting platform 4, a scoring device and a pressing device.

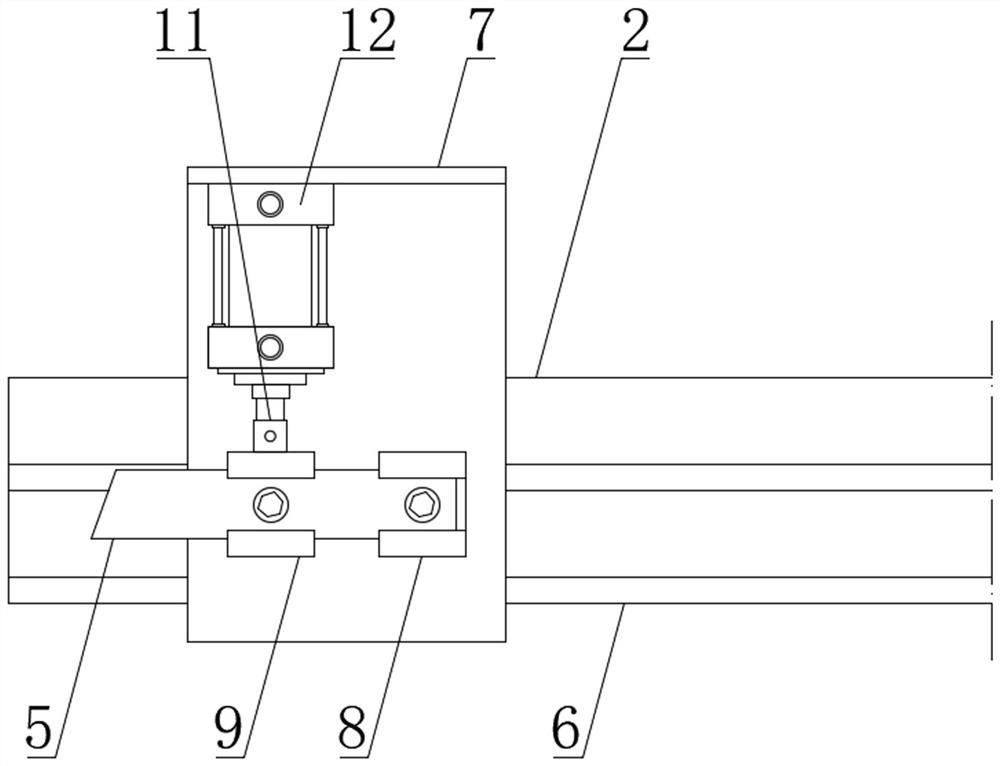

[0034] The support panel 1 is connected by bolts and fixed on the casing of the floor mat cutting machine at an angle perpendicular to the horizontal plane. The support panel 1 is provided with a rectangular through hole for accommodating the cutting device, and a support plate is built in the rectangular through hole. 2. The support plate 2 is fixedly connected to the support panel 1, and the support panel 1 provides a bearing surface with sufficient support strength for the scribing device.

[0035] The guide roller set 3 includes a feed roller and two s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com