Liquid crystal display device, manufacturing method thereof and electronic device

A technology of a liquid crystal display device and a liquid crystal display panel, which is applied in the direction of electronic equipment, lamination devices, chemical instruments and methods, etc., can solve the problems of light leakage in the dark state of the peripheral area of the display device, display defects that are prone to appear in the display device, etc., and achieve improvement Display effect, suppression of light leakage in dark state, and effect of improving adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

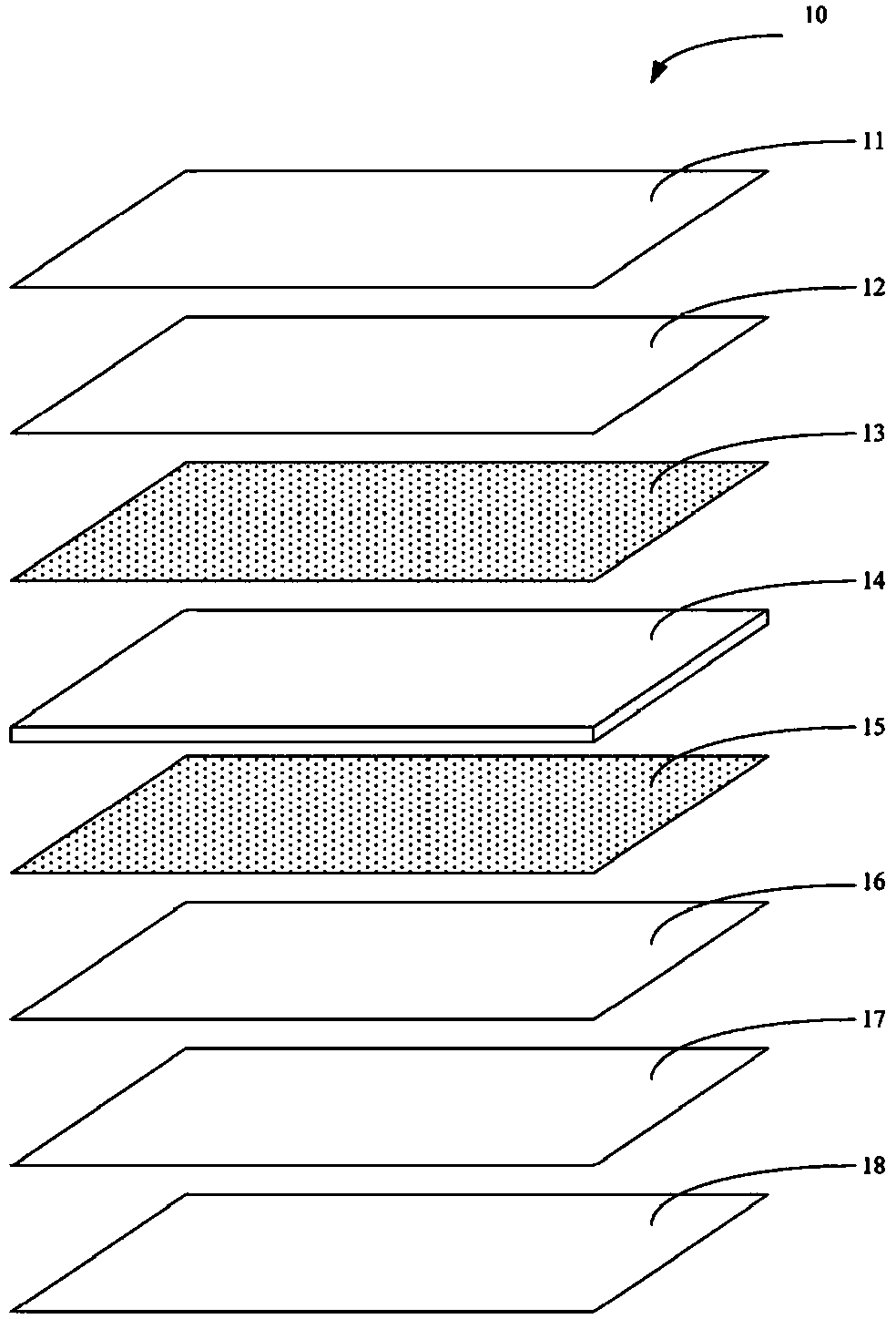

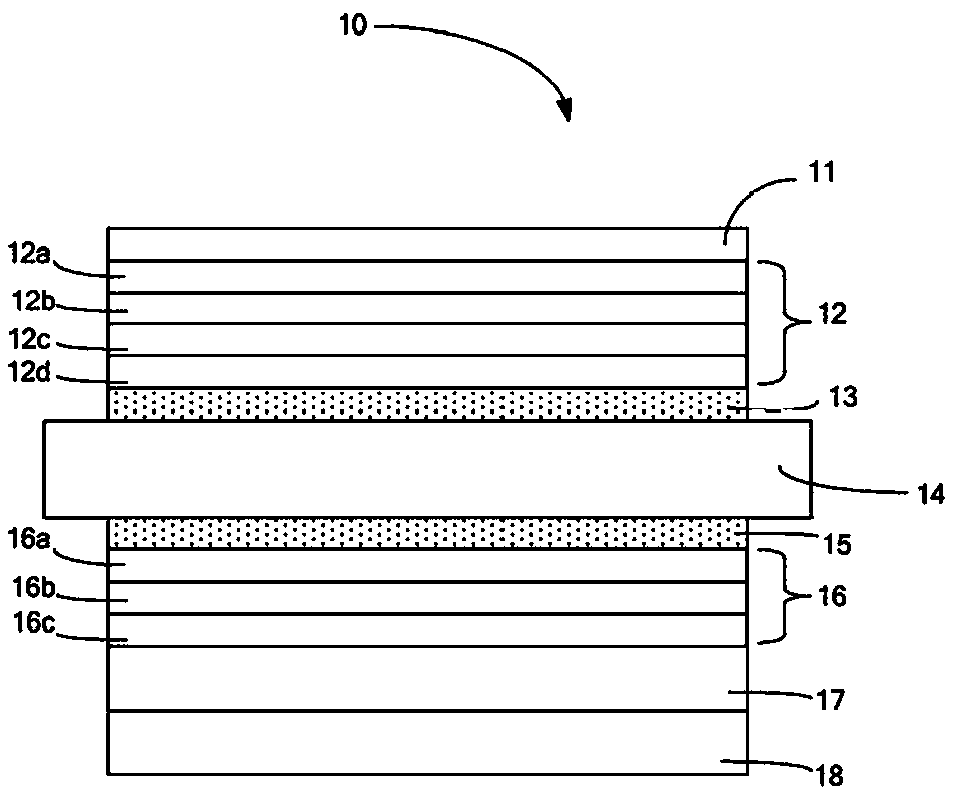

[0027] Such as figure 1 As shown, the liquid crystal display device 10 provided by the specific embodiment of the present invention includes a protective glass 11, an upper polarizer 12, an upper colloidal layer 13, a liquid crystal display panel 14, a lower colloidal layer 15, a lower polarizer 16, and a light modulator arranged in sequence. Structure 17 and backlight module 18. The light emitted by the backlight module 18 is modulated by the light modulation structure 17 , the lower polarizer 16 , the liquid crystal display panel 14 and the upper polarizer 12 and then emitted through the protective glass 11 to provide image display.

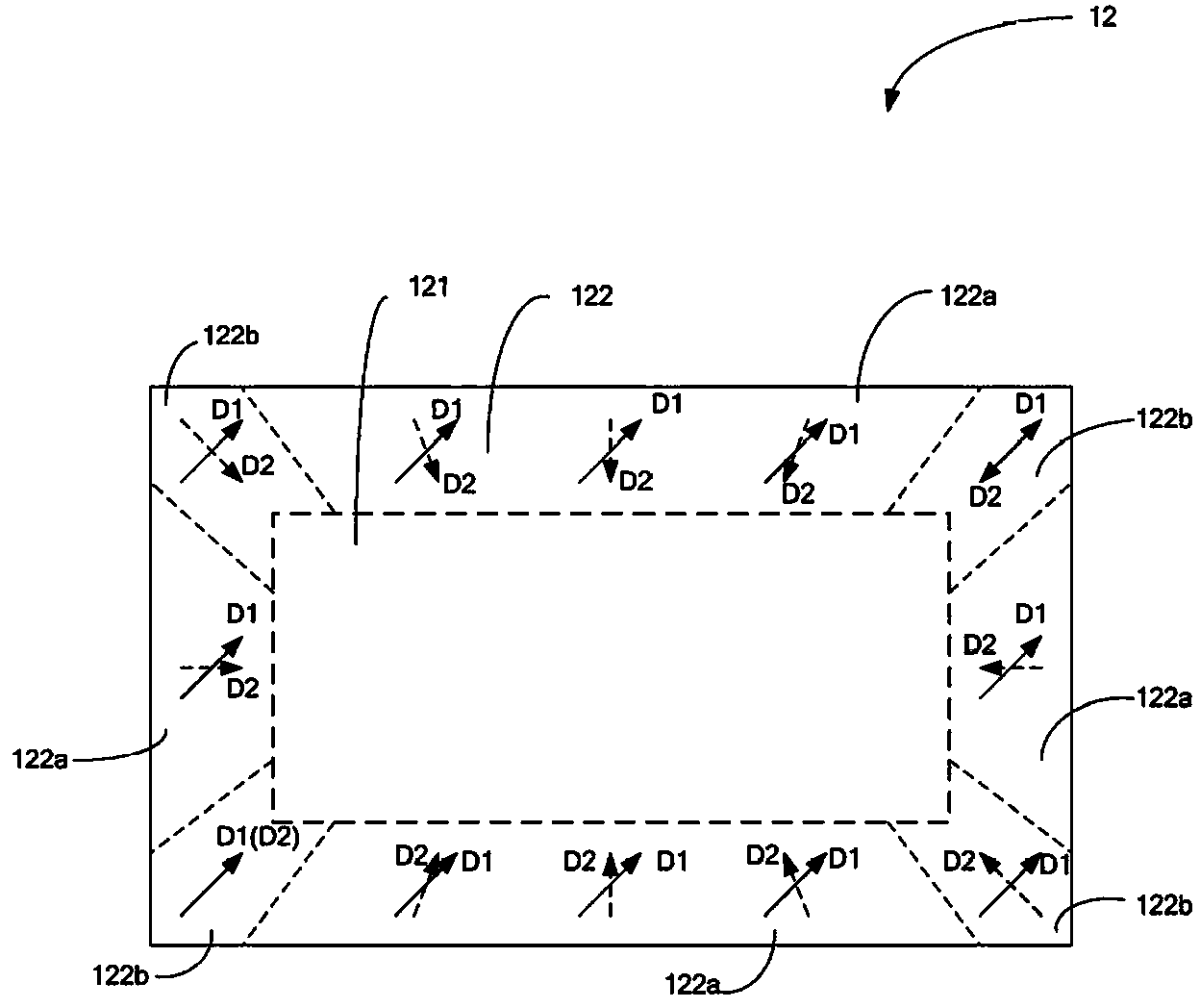

[0028] The protective glass 11 is used to protect the upper polarizer 12 . The upper polarizer 12 is capable of passing light with a polarization direction along a specific direction. The upper colloid layer 13 is used to paste the upper polarizer 12 and the liquid crystal display panel 14 together. The liquid crystal display panel 14 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com