Integrated motor endshield

A motor end cover, integrated technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of insufficient heat dissipation of the brushes, clogging of the brushes, high price, etc. Short distance and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

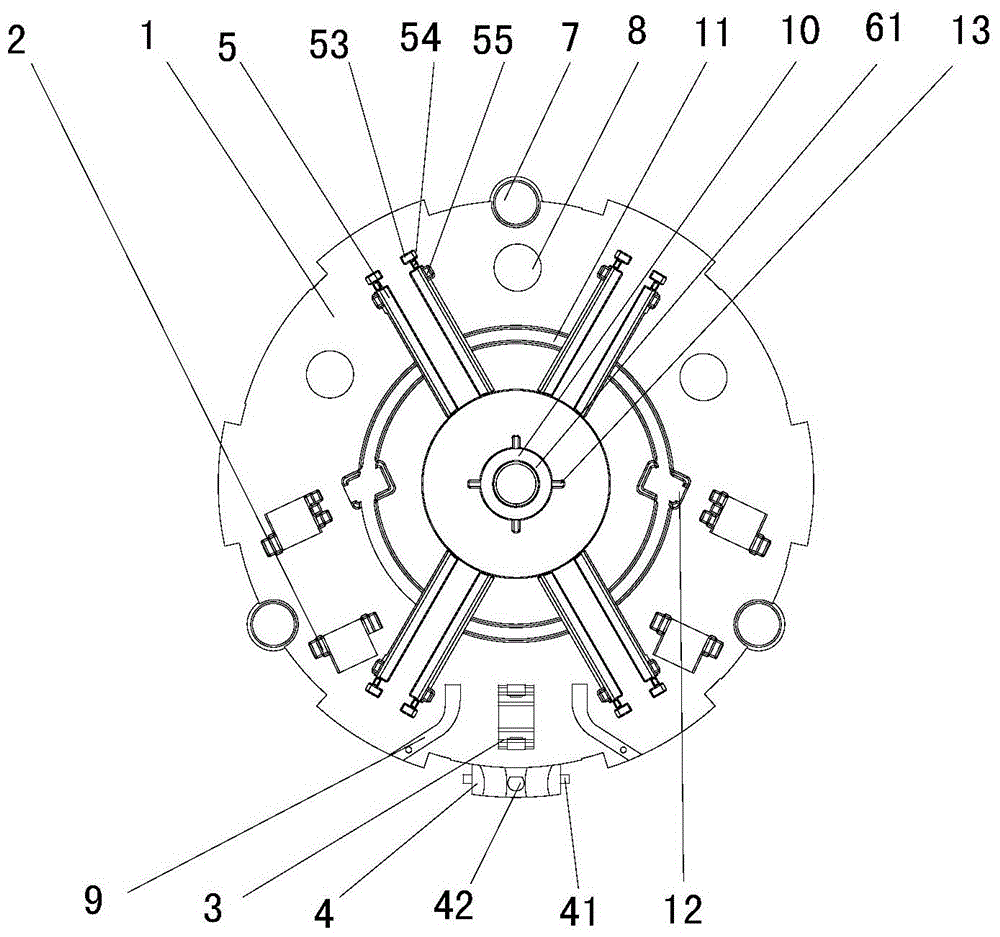

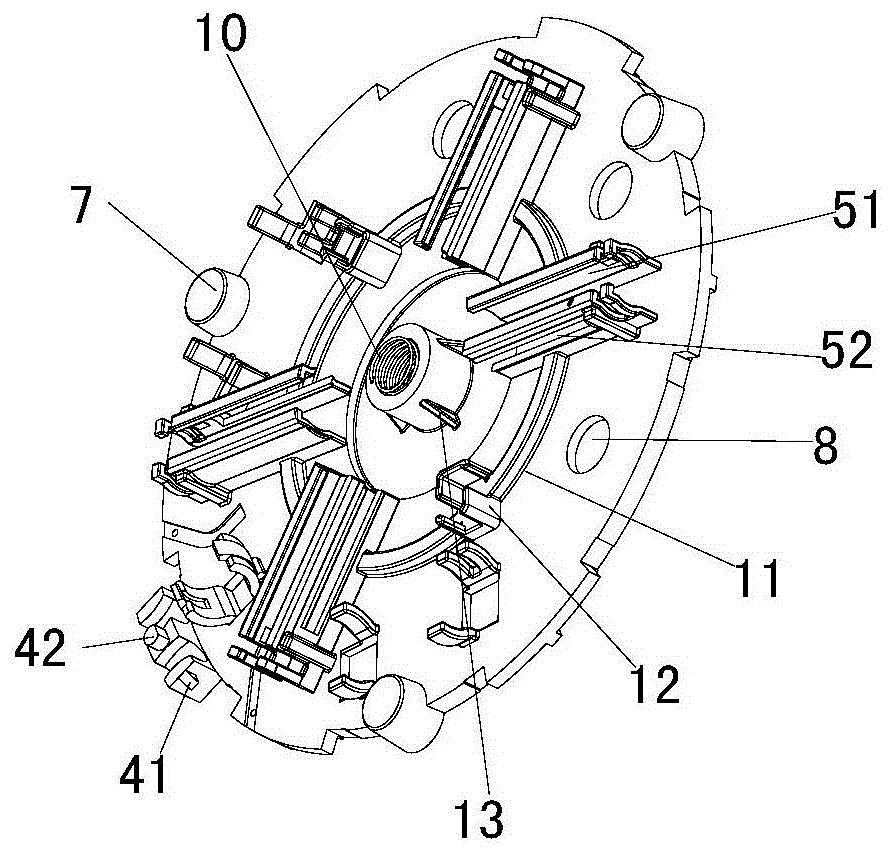

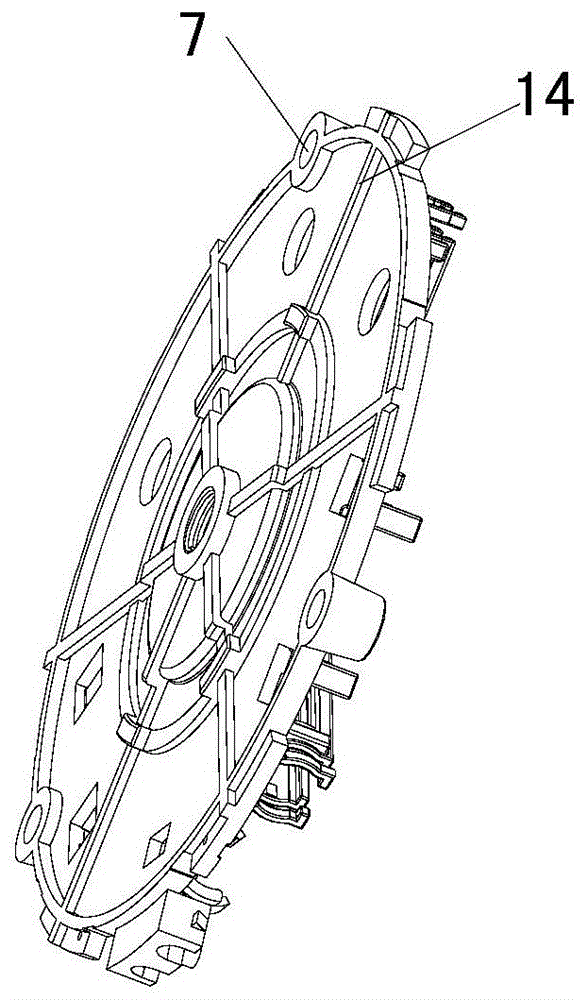

[0043] see figure 1 , with reference to Figure 2-Figure 6 , the integrated motor end cover of this embodiment includes an end cover body 1, and also includes two sets of inductance fixing clips 2 integrally formed with the end cover body, a capacitor fixing clip 3, an outlet clip 4 and four groups for installing electric motors. The concave guide rail 5 of the brush; a fixing column 61 or a bearing chamber 62 for fixing the motor shaft is provided in the middle of the end cover body, and three hole columns 7 for passing through the mounting screws are provided on the circumference of the end cover body. The main body is provided with a plurality of heat dissipation holes 8, a plurality of reinforcing ribs and two grooves 9 for installing ground plates, and a spring 10 is embedded in the fixing column.

[0044] The capacitor fixing clips in the present invention may not be provided, or may be provided in multiples.

[0045] Cooperate see Figure 6 , the concave guide rail 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com