High-voltage line insulator detecting and sweeping robot

A technology for insulator detection and cleaning robots, which is applied to instruments, measuring electronics, motor vehicles, etc., can solve the problems of easy interference, low work efficiency, and insufficient space, and achieve the effects of compact structure, reliable detection, and fast movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

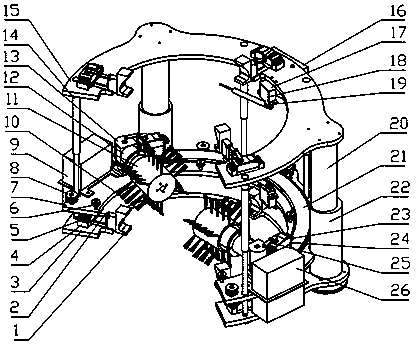

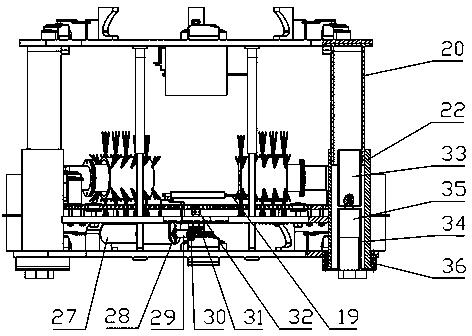

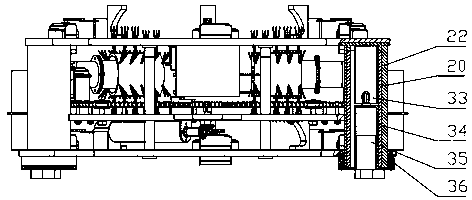

[0039] One, at first introduce the mechanical structure of the present invention:

[0040] Such as figure 1 As shown, the high-voltage line insulator detection and cleaning robot includes three layers of brackets, namely the upper bracket, the middle bracket and the lower bracket; the upper bracket and the lower bracket are equipped with several clamping mechanisms for clamping the skirt of the insulator during cleaning. The clamping mechanism can stretch and clamp the insulator skirt through the clamping drive mechanism; the middle bracket is equipped with an insulator cleaning mechanism for cleaning the insulator; the middle bracket and the lower bracket are connected and fixed by fixing rods; the upper bracket and the middle bracket are assisted by climbing The telescopic mechanism is connected. One end of the climbing telescopic mechanism is fixed on the lower bracket, and the other end is fixed on the upper bracket. The upper bracket can be driven by the climbing telescop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com