Method and device for detecting looseness of rail fastener in high-speed dynamic real-time manner

A real-time detection and fastening technology, which is applied to railway car body parts, transportation and packaging, railway auxiliary equipment, etc., can solve the problems of detection speed and detection accuracy to be improved, and achieve real-time processing requirements, easy real-time processing requirements, Intuitive effect of test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

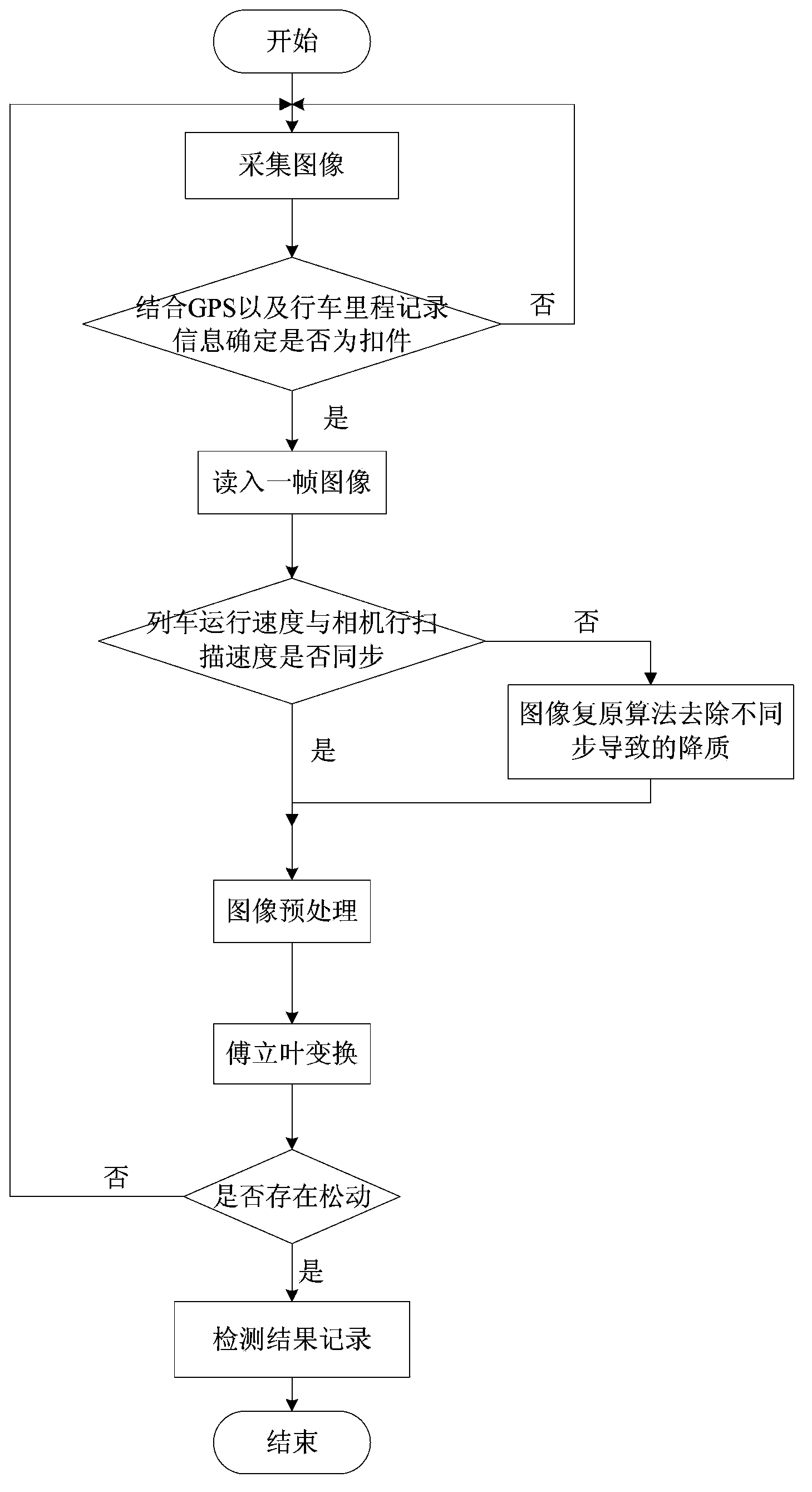

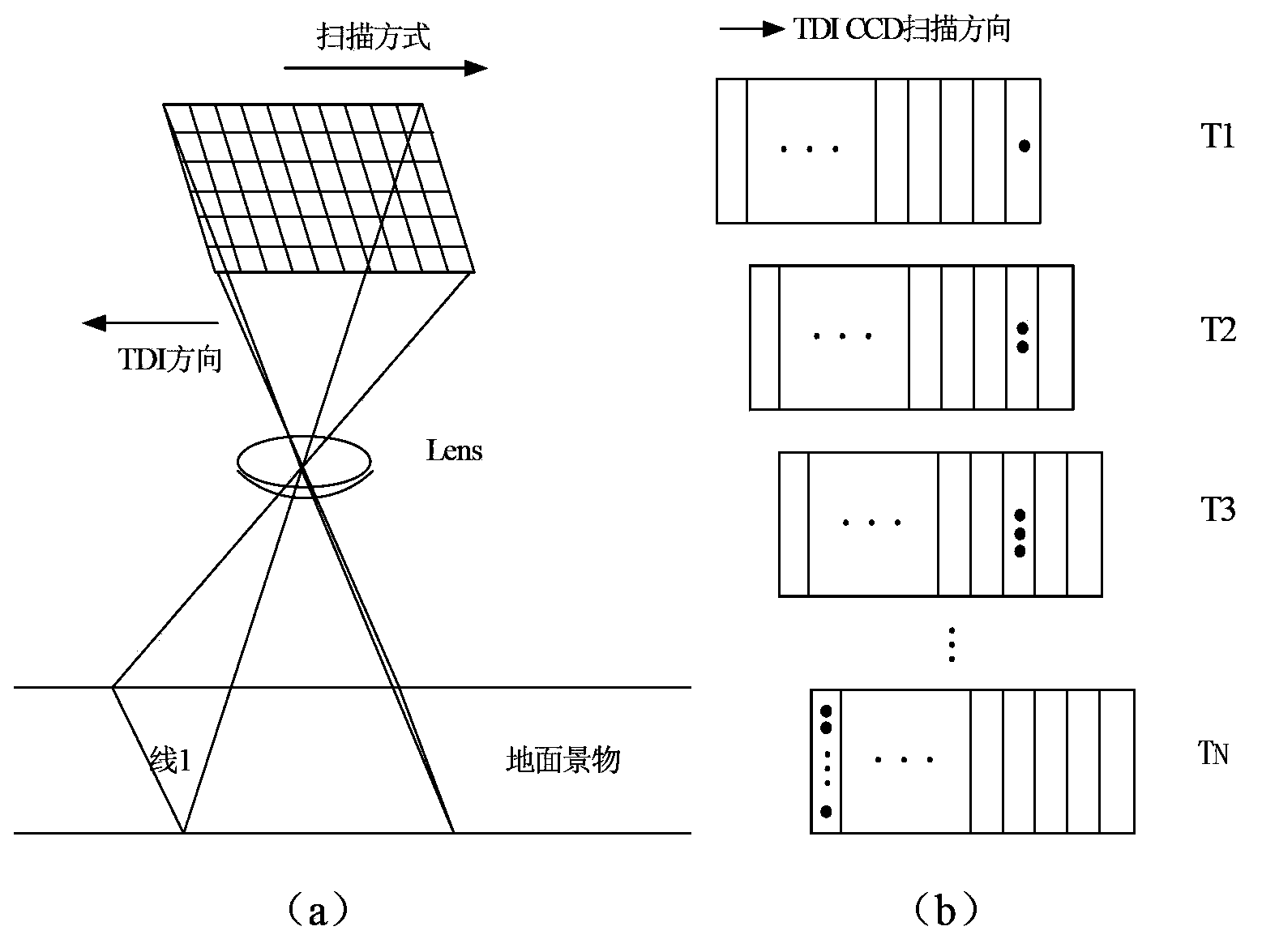

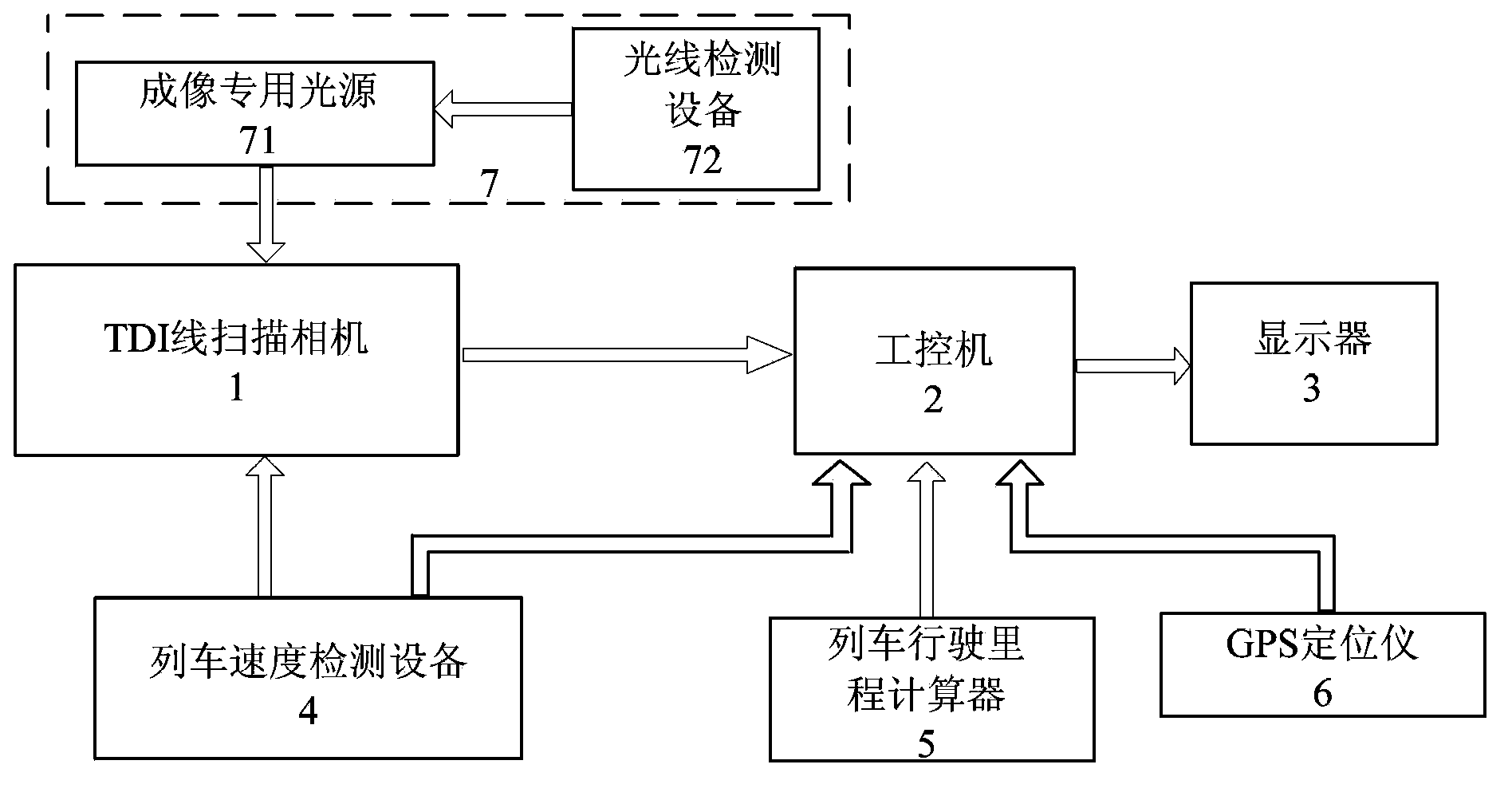

[0034] The high-speed dynamic real-time detection method for loose rail fasteners in this embodiment is a detection method based on image processing, and a TDI line scan camera is used to obtain images of rail fasteners. Such as figure 2 The schematic diagram of the working principle of the TDI line scan camera is shown, using the characteristic of TDI CCD to expose and accumulate the same scene multiple times. Multiple exposures are equivalent to prolonging the exposure duration by at least several times the TDI integral level, that is: total exposure duration = scan The time of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com